The production of aluminum alloy door and window profile can be divided into four processes: ingot preparation, extrusion molding, heat treatment and surface treatment. With the continuous improvement of people's living standards, the requirements for the appearance color of doors and windows are getting higher and higher, and with the gradual refinement of aluminum processing technology, some interconnected surface treatments have developed vigorously. The aluminum surface treatment processes we often see include electrophoresis, anodic oxidation, fluorocarbon coating spraying, etc. Here, it is very important for the editor to explain the surface treatment of the following five aluminum profiles.

I. Electrophoresis

Electrophoresis is an electrophoresis coating in the yin and yang poles. Under the action of voltage, charged coating ions move to the cathode and form insoluble substances with the alkaline interaction on the cathode surface, which are deposited on the surface of the workpiece. Aluminum profile Electrophoresis refers to the process of forming a layer of dense electrophoresis tank on the outer surface after the extruded aluminum alloy is placed within resin screen protector through direct current. The electrophoretic aluminum profile is very bright and has mirror surface result, which also improves the corrosion resistance.

Process Flow

Electrolysis (decomposition) ➤ electrophoresis (swimming, migration) ➤ electro-deposition (precipitation) ➤ electro-osmosis (dehydration)

II. Anodic oxidation

Anodized aluminum profiles refer to the process of forming a layer of oxide film on aluminum products (anodes) under the effect of applied current under the corresponding electrolyte and specific process conditions. However, the oxide film formed by the external surface of anodized aluminum is different from the common oxide film. Anodized aluminum can be dyed by electrolytic coloring. In order to overcome the defects of aluminum alloy surface hardness, abrasion resistance and other aspects, expand the application scope and prolong the service life, surface treatment technology has become an indispensable link in the use of aluminum alloy, however, anodic oxidation technology is currently the most widely used and successful.

Process Flow

Degreasing ➤ chemical polishing ➤ acid corrosion ➤ desmut ➤ anodic oxidation ➤ dyeing pretreatment ➤ dyeing ➤ hole sealing ➤ drying

The difference between anodic oxidation and electrophoresis: anodic oxidation is first oxidized and then colored, and electrophoresis is directly colored.

III. Electrostatic powder spraying

The powder coating is sprayed on the surface of the workpiece with electrostatic dusting equipment. Under the action of electrostatic, the powder will be evenly adsorbed on the surface of the workpiece to form a powder coating. The powder coating is leveled and cured by highbake, become the final coating with different effects. The spraying effect far exceeds the painting process in terms of mechanical strength, adhesion, corrosion resistance, aging resistance, etc.

Process Flow

External surface pretreatment ➤ spraying ➤ baking curing

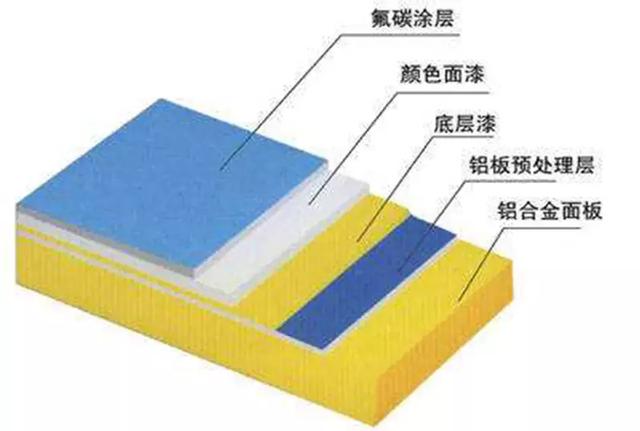

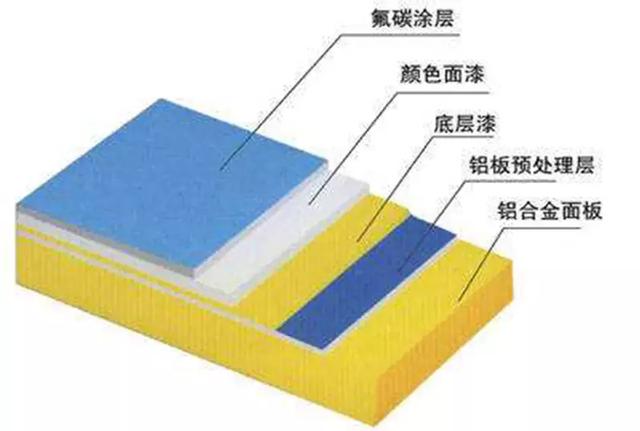

IV. Fluorocarbon spraying

Fluorocarbon spraying is a kind of Electrostatic spraying and also a way of liquid spraying. The Fluorocarbon spray coating used is made of polyvinylidene fluoride resin nCH2CF2 baking (CH2CF2)n(PVDF) as base material or metal aluminum powder as pigment. There are hanging and semi-hanging, hanging is the pre-treatment and spraying of aluminum, and the aluminum is suspended during curing. The excellent quality fluorocarbon coating has metallic luster, bright color and clear three-dimensional sense.

Process Flow

Pretreatment Process: deoiling and decontamination of aluminum... water washing... alkaline washing (degreasing)... water washing... acid washing... Chrome washing... pure water washing

Spraying process: spray primer ➤ topcoat ➤ varnish ➤ baking (180-250 ℃) ➤ quality inspection

The difference between electrostatic powder spraying and fluorocarbon spraying: powder spraying uses dusting equipment (Electrostatic spraying machine) to spray powder coating on the surface of the workpiece. Under the action of static electricity, the powder will be evenly adsorbed on the surface of the workpiece, A powder coating is formed. Fluorocarbon spraying is a kind of Electrostatic spraying and also a liquid spraying method, which is called fluorocarbon spraying and Hong Kong is called fluff.

5. Transfer wood grain

Wood grain transfer profile refers to the wood grain pattern on heat of sublimation or transfer paper by heating and pressurizing on the basis of powder spraying or electrophoretic painting according to the principle of high temperature transfer film penetration, quickly transfer and penetrate to the profile that has been sprayed or electrophoretic. Making the produced wood grain profiles have clear texture and strong stereoscopic impression, which can better reflect the natural feeling of wood grain. It is an ambitious energy-saving and environment-friendly material instead of value Wood.

Process Flow

Select base material ➤ wrap wood grain printing paper ➤ cover plastic bag ➤ vacuum ➤ baking ➤ tear off printing paper ➤ for surface cleaning