Fraud cases:

Expose a fraud about the hollow glass of home decoration doors and windows and other glass containing hollow layers (three glass and two cavity hollow, rubber-laminated hollow glass)-merchants earn unexpected money and the qualified rate of none of them.

01 if the doors and windows of the home are changed by yourself, 90% have been cheated or on the road

A piece of glass occupies more than 70% of the area of doors and windows. In the past, it was important for lighting at home. Up to now, it can strengthen sound insulation and heat preservation to meet the needs of different groups, glass has become an increasingly important part of doors and windows.

However, hollow glass, as the glass type with the largest usage in home decoration doors and windows at present, could have brought better sound insulation, heat preservation and beautiful use experience to the home;

However, due to the existence of a group of people, 90% of home decoration owners (whether you are a second-hand house decoration, self-built houses or a new house, balcony, window change, etc.) hidden dangers of poor performance and safety are covered:

These cases all come from fans of brother peng. Brother peng has received nearly 100 such cases. The main culprit behind them is: small hollow glass production workshops that cut corners, are crude and undisciplined (probably on the street, may be hidden in the corner of a door and window processing plant)

Behind these cases, there are tens of thousands of similar accidents that will happen or will not be detected. Because the small workshops that make these glass and the merchants who sell these glass are not good at it:

1) Home decoration doors and windows do not have professional supervision like engineering;

2) the hollow glass area of home decoration doors and windows is not large, and it is difficult for consumers to detect the defects such as error, thickness, smoothness, water ripple and strength;

3) hollow glass will be wrapped into the door and window frame, and the quality problems such as error, thickness and sealing treatment will be covered up;

4) consumers don't care about and don't understand. They don't feel much about the performance and don't know what kind of quality requirements they need for glass.

Most consumers will not find quality problems until there is water vapor in the hollow glass, and the reaction is helpless: Oh? How could this happen! Huh? Isn't it just two years ago! Alas, forget it, what can I do even if I find a merchant!

The drivers behind these cases are: balcony packages in various forms in the community (maybe it is still a small workshop itself), small couple shops on the street (maybe it is still a small workshop itself) even there are some brand stores in the mall, which use a lot of glass without quality.

It may be to "control costs" or to seek price difference. In short, most of the merchants deliberately do not cooperate with local reliable glass deep processing enterprises and do not buy compliant glass. We specially choose three small workshops operated by relatives that have no license, no professional equipment and do not produce according to the standard to purchase hollow glass (or they themselves are such small workshops).

02 hollow glass production process in small workshops 」

Before mentioning the "hollow glass manufacturing process", we should first understand why small workshops are popular? Why do businessmen often say that my glass is South glass (North glass, Faith)? There is no hollow glass filled with argon gas; Glass has no warranty.

Because in addition to some big-name door and window enterprises operating hollow glass production lines themselves, most door and window owners who come into contact with consumers usually buy finished windows from door and window factories (semi-finished products are assembled by themselves), at the same time, buy hollow glass in the local glass factory and assemble it in the warehouse or customer's home.

Originally, the regular glass factory did a good job: the production line of hollow glass & rarr; Glass cleaning and drying & rarr; Aluminum spacing strip filling desiccant, sealing sealant & rarr; Glass chip combination & rarr; inert gas (generally not charged) & rarr; The second glue seal (now there is a fully automatic combination machine) & rarr; The production is completed & rarr; Delivered to the door and window manufacturer.

The small workshop has a brainwave. If the door and window owners all buy glass from regular glass factories, the cost is much higher! Anyway, consumers are stupid and don't understand anything. Why don't I buy some glass with good cut size from the glass factory? My wife and I will take care of the next piece and glue filling, sell it to the door and window boss at a cheaper point to earn the difference.

This is a win-win situation! Do as you say:

Desiccant (scientific molecular sieve, which is the same as desiccant in food, is resistant to water vapor penetration and air permeability)? Absorbing the water vapor inside the hollow glass is nothing! I just don't fill it up or even don't fill it up! You can't see it, it is better to save cost calculation!

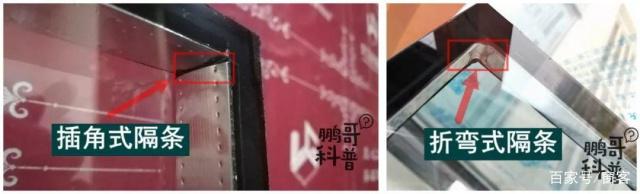

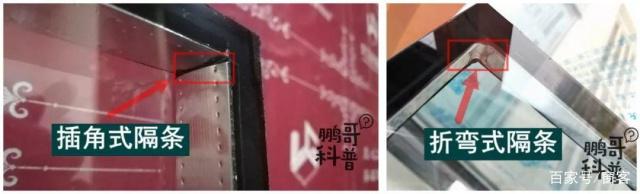

Aluminum spacing strip (bright silver between hollow glass, supporting)? This can't be saved, Hey Hey, but I also have a way! Although you can see it, you can't stop me if I buy a poor quality one. What! Now the aluminum spacer with the popular bending process, only one splicing seam barrier can make the glass quality better?

No, no, it costs tens of thousands of yuan for bending machine. I have no place to put it after buying it! I am still honest and useful with the original angle-inserting craft. XINGX points are practical, and children at home can help me insert it!

Butyl rubber (the first seal of hollow glass, water vapor resistance, good air permeability, very important), I only have craftsman small brushes, I can't apply it evenly if you give it to me (it is required to apply evenly and continuously, and the temperature heating glue is required. The processing plant is plain like a machine in the video)

Besides, this glue is still so expensive. I will use double-sided glue for you, that is, I have a conscience. Generally, my peers don't stick it! What I can't see costs me. I really want to tell you! Oh no, I can't tell you, but I have to count fifty cents of the cost on you.

Chip combination machine (the automation equipment of the processing plant uses force to evenly combine two pieces of glass on the barrier)? Ha ha ha, where can I put such a big equipment? I can't even afford a bending machine and buy a chip machine? It doesn't matter if you are fully automatic. My wife and I are one hundred and five for each person. After two pieces of glass are put, each person will sit on one side to ensure that the pressure is solid. It is not more cost-effective than the machine combination machine! No more, save ten yuan!

Filling argon gas (normal manufacturers can calculate a value-added service depending on the situation. Argon gas has worse thermal conductivity than ordinary air. When the area of single hollow glass is large, argon gas must be filled to ensure the flatness of glass)? Hard-working things, anyway, you (don't understand), just pretend to be fully understood, yes! Charging argon is a lie!

The second seal (directly related to the service life of hollow glass, there are three types of glue in the mainstream market: polysulfide glue, silicone adhesive, polyurethane glue. Polysulfide glue has good water vapor penetration resistance and air permeability resistance, silicone adhesive UV resistance and good durability).

The last process is really poor. The glue is so expensive and the usage is still so large, so I can't give people a living! Hey, there is, poor glue, kerosene, and water. Why is the cost low. Durable service life? Hey Hey Hey, I won't say it, fools, guess it!

Finally done! Hey? The country also has standards for insulating glass: How many millimeters should the thickness difference, diagonal difference and thickness difference of adhesive layer not exceed? What are the requirements for dew point (the temperature of condensation in the air layer of insulating glass) and what is the weather resistance test?

The glass is installed in the window frame anyway! Why are there so many requirements. I don't listen to the national hollow glass standard, I don't care, I want money.

If you ask GAO to find someone else, I will recognize these tricks:

1) the glass is from south glass (north glass, xinyi). There is nothing wrong with what I said, but the original piece comes from south glass, which has little influence on the quality of hollow glass and you don't understand.

2) there is no hollow glass filled with argon, yes, our small workshops do this, and we do it in the home decoration market, so there is no one filled with argon!

3) There is no warranty for glass. Of course, what regular manufacturers do has a service life of 15 years, of course, they can guarantee it. We make good products. One year's life span and two years's life span depends on mood and luck. Warranty is not cost! Ghost gives you a warranty!

A look at the balcony, small couple shops on the street, and brand shops in the mall. Oh, this is really good. The small workshop is so smart! Buy their home to make more money, cooperation and cooperation! (Others simply do the same yourself) glass factory fool! Consumers are stupid!

03 the scourge of non-compliance hollow glass, and its national standards

In this way, non-compliant hollow glass and other products flow into the home decoration market in large quantities, but consumers are always kept in the dark. When purchasing home decoration doors and windows, consumers "look at the door and window brands at best, choose the door and window series, choose the door and window type, and pay attention to the profile brand, series structure and glass type at most. I am not used to asking: where is your door and window factory address? How is your supply chain? Where is your glass processed? 」 The disadvantages are used seamlessly by bad merchants.

But Peng Ge Xin thought that passive consumers were completely due to the wrong information with merchants before. As long as more and more consumers know the importance of glass and know the performance of inferior glass and compliant glass, use difference, see how you people live!

Therefore, Brother Peng wants to let consumers simply understand some places that do not conform to national standards and the consequences caused by this in the following two chapters. And how consumers are most likely to purchase compliant glass.

There are detailed regulations on the size deviation of insulating glass in the national standard, such as length width, thickness difference, stack difference, diagonal difference, the allowable deviation of stacking difference is about ± 1 ~ ± 3mm (depending on the size of the area), which involves the precision of the processing machine and the proficiency of the processing personnel.

Because the machine is not good or the workers look at the mood, consumers are likely to observe obvious dislocation of two pieces of glass in inferior hollow glass and the thickness is less than standard specifications (obviously the merchant said that the glass thickness is 5mm hollow glass, the actual measurement of each piece of glass is only 4.3mm).

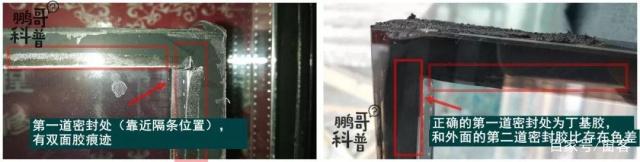

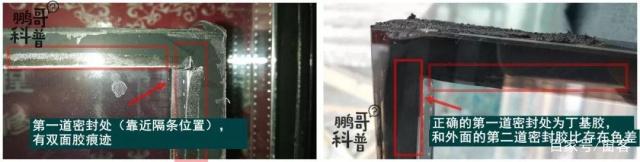

There are some regulations on the appearance quality of insulating glass in the national standard, such as the first seal (yes, the place where stupid merchants stick double-sided adhesive tape, I really don't know what they think) the glue should be applied evenly and continuously (very important), and the second seal (the thick black glue on the outside of the glass) should be uniform, without broken glue, and the glass should be less scratched or not scratched, aluminum spacing strip flat without distortion (that is, it looks smooth), and there is no foreign matter in the hollow glass. This involves insulating glass materials and production environment.

Due to the poor production environment and the supply of materials not considered, consumers are likely to observe the first incomplete seal or double-sided adhesive tape in inferior hollow glass (believe brother Peng, this kind of glass is quite a lot), there are small stains in the glass, and there are bursting edges (breakage) on the surface edge of the glass. The second seal falls off at a glance, too hard or too soft (good elasticity), and smells (the taste of inferior glue is unbearable, and it smells like rotten eggs or fart?).

In the national standard, there are also testing items such as dew point for insulating glass, that is, it is necessary to ensure that qualified insulating glass can be used for 15 years under normal circumstances. This is also the biggest disadvantage of inferior hollow glass mentioned by Brother Peng above: there is no water vapor in the hollow layer after 2 to 3 years of use, water droplets are fine (the hollow layer has water vapor, which means that this hollow glass has failed).

Non-compliant inferior glass also has great potential safety hazards, especially the dislocation of the glass, the stolen thickness of the glass and the poor glue used for the second seal, which greatly affect the strength of the glass. If the strength is not up to standard, the glass of doors and windows will shake and be fragile.

04 identification of advantages and disadvantages hollow, and resistance as consumers

Finally, Brother Peng himself summarized seven simple methods for distinguishing the advantages and disadvantages of hollow glass, some of which have been mentioned above (just mention it briefly):

1. Three-way question to determine whether the merchant's glass has reliable sources when purchasing doors and windows

I asked you where the glass was produced, and secondly, what is the home of the glass deep processing factory (composite)? Three questions, is there any manufacturer's photo?

The boss is arrogant and unclear. It is very likely that the glass produced by the small workshop is the glass. If the boss can guarantee the quality of the glass, show you the manufacturer's photo, or tell you the manufacturer's name, you can pass the photo, you can initially determine whether the glass source is reliable through online search and on-the-spot investigation.

Then it is divided into two steps. If you walk into the mall, there is generally no stock glass in the store, so you can only look at the sample window or wait until the glass is shipped to your home to check the authenticity of what the boss said; if you enter a store with glass inventory such as a street store, you can directly check the authenticity of the boss. The identification method is as follows:

2. The First Seal (important and easy to identify)

Identification method: the normal sealant is lighter than the second seal and continuously opens; However, small workshops are likely not to apply or use double-sided adhesive tape.

Note: This method is only useful when the glass is not framed.

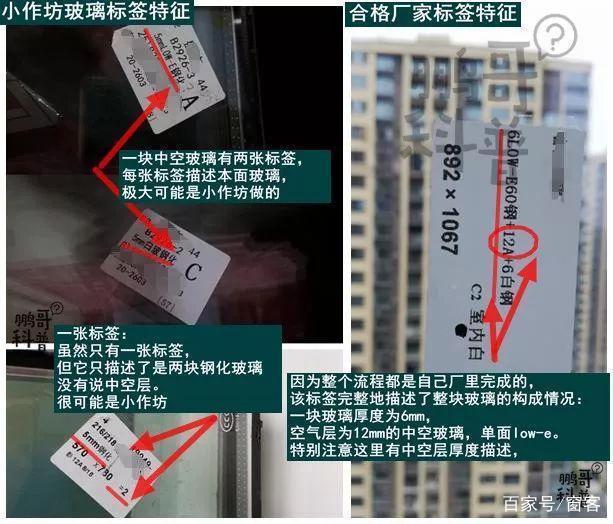

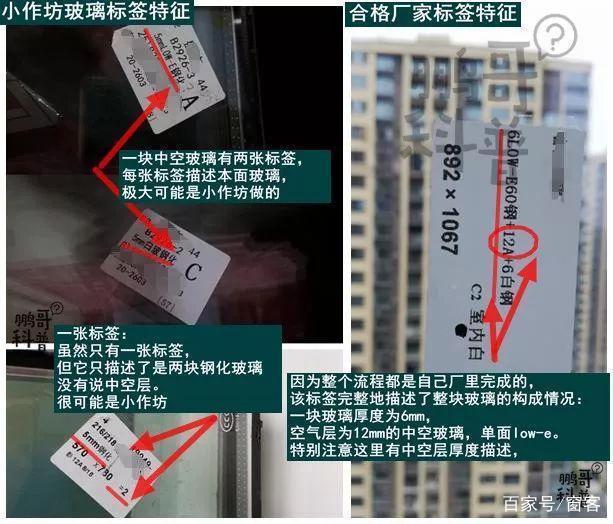

3. Look at the label (easy to identify)

Identification method: when the glass manufacturers peng met in hangzhou deliver the glass to the customer's home, they will leave label marks on the glass. If this piece of glass is produced by a powerful regular manufacturer, its label describes the whole piece of glass; And because the small workshop bought two pieces of glass of the same size separately from the glass manufacturer, it was combined by itself, so the label they used would not describe the whole hollow glass.

Note: it is only applicable to tempered glass (only tempered glass has labels, and small non-tempered glass workshops can cut it by themselves)

4. Look at the aluminum Spacer (crucial and easy to distinguish)

Identification method: look at the bright silver aluminum spacer between hollow glass. If the four corners of barrier are inserted corners with gaps, it may be produced by a small workshop; If it is self-curved seamless gap, it may be produced by regular manufacturers.

Note: it is not excluded that some compliance manufacturers are still using angle insertion technology, but small workshops will never use bending. This point is that we would rather kill mistakes than let them go.

5. Look at the second seal (difficult to identify)

Identification method: one look, two touches, three smells, one look, the second seal is not regular enough, two touches, whether the second seal drops, whether it is too hard or too soft (good elasticity), three smells bad (the smell of inferior glue is unbearable, and it smells like rotten eggs or fart?).

6. Look inside and outside the hollow glass (it is very important and easy to distinguish)

Identification method: the hollow glass of small workshops is prone to dislocation (important), the phenomenon that the thickness of single glass is not up to standard (life and death), and the phenomenon that small stains exist in the glass, the surface edge of glass has the phenomenon of bursting edge.

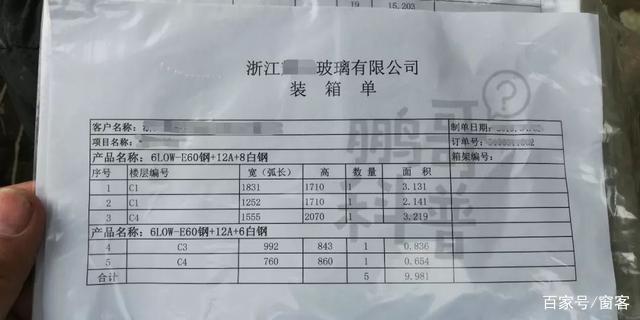

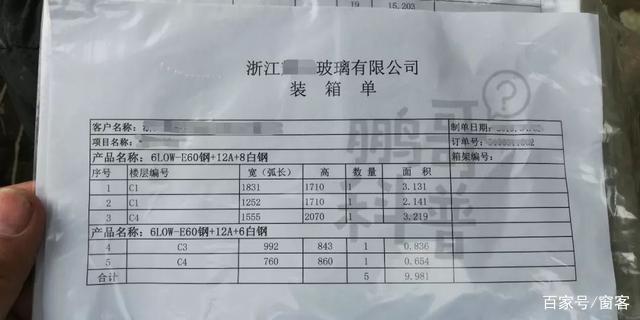

7. Ask if there is a packing list (easy to identify)

Identification method: regular glass manufacturers have their own delivery process, you can ask for it from the merchant

Through the above seven identification methods, the authenticity identification mentioned by the merchant can be realized relatively simply. While purchasing one more guarantee for yourself, (finding inferior glass does not match the seller's promise, let him lose three if he does! Tips: prepare evidence, recordings, contracts, etc. in advance)

The sound insulation glass is not all a lie. What lies to you is that the developer uses the hollow glass as the sound insulation glass, in fact, the real DEV glass, a professional sound insulation glass, is formed by pressing three layers of glass with different resonance rates together with two layers of ev film, the sound insulation is completely fine to deal with the noise on the road.

In fact, there are still sincere soundproof windows. The following cases:

Our family has been paying attention to the issue of soundproof window. I don't know if everyone is the same as us.

My downstairs is a big road, very noisy, I am old house.

I didn't know there were soundproof window products before, but later I really couldn't stand the noise, so I found du niang (I want to say there is a problem to find du niang) and it must be right.

Ha ha, sure enough, I found many companies about installing soundproof window.

As a result, I spent nearly half a year asking about which company is formal and which company is really powerful.

Finally, I made an appointment to talk in person (I won't say all the names of the merchants).

I didn't intend to talk about it, but recently I have seen countless netizens being cheated by irregular soundproof window companies.

Some say that the effect is not as good as that of their original window, or that the installation staff's attitude is extremely bad, and the goods are transported by express delivery, etc. I feel cheated.

Suddenly, I feel lucky and want to share it with you. I hope you can get some useful information through my post.

Let me just say the details of my choice (I can secretly say that I am glad that I chose the right one?)

First: everyone is very concerned about the price. The price of this store can be said to be medium-sized. (There are many businessmen who are black-hearted, and their opening is thousands of square meters, which makes me lose the mood to continue to understand)

I installed two types, one is a three-layer composite vacuum soundproof window, and the other is a three-layer composite vacuum laminated soundproof window (soundproof window the company's statement is called overclocking period soundproof window).

The price offered by his family is 800 yuan per square meter, and the price of laminated yuan per square meter is 960 yuan.

One window in my bedroom, with balcony window, laminated in my bedroom, vacuum in balcony, final transaction price, vacuum 760 yuan/square meter, 880 yuan per square meter for laminated.

Very small price. But the effect is really seen.

Second: We are also very concerned about service. After all, no matter before or after sales, we don't like trouble or quarrel.

Let's talk about pre-sales first. A fat young man came to talk to us. It was very kind. It can be said that he did what he said. Not pompous.

A must-ask type.

There is no problem with the after-sales service. I don't know yet. Ho ho.

Third: when installing. They arrived at the same car as the installation master and the window. The installation master was basically 40 or 50 years old. That experience is definitely talented.

I don't know much about the technology, but looking at their installation process, I want to say it is professional and won't mess things up.

Fourth: acceptance, I am very impressed by this point.

There was a little problem with one of the windows. I said that's it. I also plan to pay them the full amount (here is to say, here is to pay for the effect, there is no need to pay a deposit in the early stage. Very secure). Their master said: they were not satisfied, and they had to repair it for me, saying that they would deliver the goods only if they were the most well-deserved.

Let's be a warm customer.

Finally, I want to say that the effect is really good. I basically don't have to close the original window now. When I first started to install it, I will leave a little small seam specially (abnormal statement: A little too quiet and not used to it)