Article 1:

Broken Bridge aluminum doors and windows what glass to use

Of course, it is suitable for insulating glass. This kind of product is superior to ordinary double-layer glass due to various properties such as heat insulation, sound insulation, bees, frost prevention, dust prevention, etc. It also has the following features:

A. Thermal insulation performance: the coefficient of conduction heat k is less than 3.0kw/mm.k.

B. Sound insulation performance: But the incoming external noise is reduced by 27-53 decibels.

C. Sealing performance: not easy to enter dust.

D. Stable performance: not easy to break, resistant to wind pressure, long service life.

2. How to choose broken bridge aluminum doors and windows?

1. Profile wall thickness

Most door and window manufacturers in the home decoration market choose products with high output rate, that is, products with relatively thin wall thickness to reduce the cost. Some small manufacturers produce 1.2 mm-1.3mm thick is lower than the national standard, but the national standard stipulates that the thickness should be greater than or equal to 1.4mm;

Broken Bridge aluminum profiles are usually divided into 60 series (6cm) and 70 series (7cm), while the quality of broken bridge aluminum doors and windows depends not on which series of profiles are selected, but mainly depends on the material, wall thickness of broken bridge aluminum doors and windows, heat insulation strip, processing technology, etc.; The residential area is relatively quiet, and the windows are not very large. It is enough to choose 60 series profiles. If the residential area is facing the street and floor windows, it has high requirements for sealing, sound insulation and heat preservation, 70 series profiles can be selected.

2. Sealing design

Different brands of profiles have different sealing designs, including three, four, five, six, seven, nine, and even ten sealing designs, however, the raw materials produced by the top ten broken bridges aluminium formation product factory in china are two sealing strips opened outside and three sealing strips in-swinging casement window. In order to meet the needs of consumers, many aluminium formation product factory broken bridges in china produce aniseed broken bridge aluminum doors and windows, increase the track that can wear rubber strips inside, so that bridge-breaking aluminum merchants can wear rubber strips by themselves, thus the so-called series of seals appear. Theoretically, the more seals, the better the heat preservation effect, however, there is no corresponding monitoring evaluation and explanation from authoritative departments.

3. Supporting accessories

When consulting the price of broken bridge aluminum doors and windows, you must ask whether it includes the cost of supporting accessories such as beam, column, flat hardware, locator, car window shade, waterproof adhesive, and Styrofoam, because many broken bridge aluminum merchants have quotation traps, in order to attract customers, they first lower the unit price, and then the merchants pay a variety of auxiliary materials to make up the difference. However, the cost of these auxiliary materials usually costs several thousand yuan, and the final total price is not cheap at all.

4. Add auxiliary frame

The secondary frame is also called attached frame and protective frame. The door and window frame is fixed on the wall and is used to install basket of doors and windows. It is generally used for 70 series and below profiles. If the window needs to be covered with window frame (window opening), tiles need to be pasted around the window, when the ceiling is needed at the top of the window, the attached frame needs to be added, because the frame of the 70 series and below profiles is relatively narrow, which will hinder the opening of doors and windows. The advantage of installing the sub-frame is that there will be gaps on both sides of the doors and windows after installation, which is not very beautiful. After adding the sub-frame, the gaps can be covered, which is equivalent to the matte of the doors and windows in function, however, additional frames need to be charged separately.

According to the above, broken bridge aluminum doors and windows is generally made of solid stainless steel and some transparent glass, which makes them look beautiful outside. After long-term use, there will be no loss, so it is a new product with multiple factors of practicality and high cost performance. Furthermore, it can be found that the glass used in Broken Bridge aluminum doors and windows should also be paid special attention to in terms of selection, we can comprehensively understand for a rainy day, and believe that this can achieve satisfactory results.

Article 2:

We know that 30% of the area of a single door and window is the material frame, 70% of the area is mainly glass, the quality of glass, sound insulation and thermal insulation have a crucial influence on the overall energy saving of windows.

1. What are the common broken bridge aluminum glass configurations?

Ordinary hollow glass, tempered insulation glass, laminated hollow tempered glass, LOW-E hollow glass, LOW-E hollow laminated glass, which are also several common broken bridge aluminum glass configurations, and of course, better dimming glass, etc, the same broken bridge aluminum window is equipped with different glass, which makes great difference in heat insulation and energy saving. Don't underestimate the function of glass.

2. What are ordinary hollow glass and tempered insulation glass?

Ordinary hollow glass means that after the glass factory cuts off sheet glass according to the glass size of the customer, the glass cover is bonded with the aluminum alloy frame containing desiccant, and the composite binder with high strength and high air tightness is used around, seal two or more pieces of glass, fill dry gas in the middle, and fill the frame with desiccant to ensure the dryness of the air between glass cover.

Tempered insulation glass refers to putting the cut glass into sheet glass for heating on the basis of ordinary toughening furnace, then moving the glass out of the heating furnace, and then blowing high-pressure cold air to both sides of the glass with multi-head nozzle, the tempered glass can be made by cooling it to room temperature quickly and evenly. After the tempered glass is obtained, the hollow composite sheet is carried out to obtain tempered insulation glass, the tempered glass has higher strength and hardness than ordinary glass, which is also called safety glass.

(If the consumer budget is limited, at least tempered insulation glass should be standard)

3. What is LOW-E glass?

Low-E glass, also known as low-radiation glass, is a film-based product composed of multi-layer metal or other compounds plated on the glass surface. Its coating layer has the characteristics of high transmission of visible light and high reflection of COSCO infrared ray, which makes it compared with ordinary glass and traditional architectural coated glass, it has excellent heat insulation effect and good light transmission.

By using Low-E glass to make doors and windows of buildings, the transmission of indoor heat energy caused by radiation to the outside can be greatly reduced, achieving ideal energy saving effect. Other significant benefits brought by the reduction of indoor heat loss are environmental protection. In cold winter, the heating of buildings emits harmful gases such as CO2 and SO2, which are important pollution sources. If Low-E glass is used, by reducing heat loss, the fuel consumed by heating can be greatly reduced, and the emission of harmful gases can be reduced. Therefore, the benefits of using LOW-E glass in residential buildings are obvious, and more and more people begin to choose LOW-E glass.

Taking a 120-square-meter residential building in Shandong as an example, using LOW-E glass can save 781 yuan for heating, 232 yuan for refrigeration and 1013 yuan for comprehensive energy saving every year, especially for those who use floor heating and fresh air systems at home, LOW-E glass should be used, thus saving a sum of money every year.

4. Will LOW-E glass affect lighting?

The answer is that there is basically no effect, because the light transmittance of ordinary white glass is 89%, while the light transmittance of high-permeability LOW-E glass is over 80%, so choosing high-permeability LOW-E glass will not affect the lighting at home. (High permeability LOWE glass is most suitable for northern cities)

5. What kind of glass has good sound insulation, good heat insulation and energy saving?

Answer: LOW-E hollow laminated glass, this kind of glass cost is relatively high, generally suitable for villas or residential areas with noisy living environment, of which LOW-E glass ensures the thermal insulation of windows, laminated glass has sound insulation effect again. The combination of the two forms hollow glass. The energy saving effect is very good, but the price is not cheap. In this price-comparing era, many consumers only care about the price, don't pay attention to what glass you use, or energy saving, etc.

(If the economic conditions are limited, and if you want to reinject heat insulation and energy saving, you can choose high permeability LOW-E hollow glass, the price is not very expensive, and the cost performance is very high)

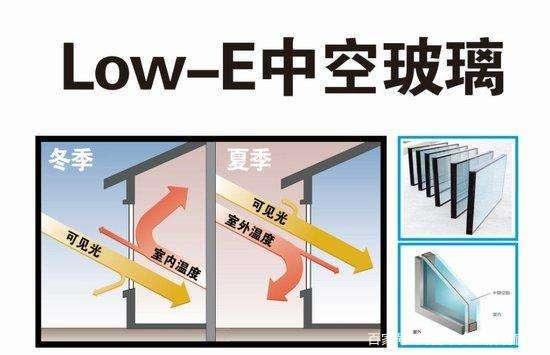

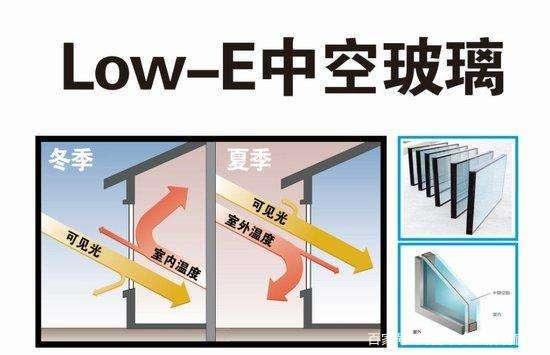

6. How does Low-E glass work in summer and winter?

In winter, the indoor temperature is higher than that of outdoor, and the far infrared heat radiation mainly comes from indoor. Low-E glass can reflect it back to indoor so as to keep the indoor heat from leaking out. For some solar radiation from outside, Low-E glass can still allow it to enter the room. This part of energy is absorbed by indoor objects and then converted into far infrared thermal radiation and left indoors. In summer, the outdoor temperature is higher than indoor, and the far infrared heat radiation mainly comes from outdoor. Low-E glass can reflect it out to prevent heat from entering indoor. For outdoor solar radiation, you can choose Low-E glass to limit its entry into the room, thus reducing refrigeration costs (air conditioning costs).

7. Is LOW-E glass facing outward or inward when installing?

Hollow glass has four surfaces, and the number from outdoor to indoor is 1#, 2#, 3# and 4# respectively. In areas where heating demand exceeds refrigeration demand (northern region),Low-E film layer is located on the 3rd surface. (That is to say, when installing LOW-E hollow glass for doors and windows in northern areas, LOWE glass should be installed on the indoor side)

On the contrary, in areas where the demand for refrigeration exceeds the demand for heating (southern regions), the Low-E film layer should be located on the second# surface. (LOW-E hollow glass should be installed in the South, which should be installed on the outdoor side)

For example, Shenzhen is hot most of the year. lowe will be printed on the outdoor glass, blocking light and temperature from the outside. In the north, it is usually in the indoor side glass, which prevents heat from being lost from indoor to outdoor.

, suggestion: there is no absolute position for the installation of LOW-E glass. It depends on your personal situation. For example, if you are from the northern region, your home is self-heating, and the air conditioner is less in summer, then Low-E glass will be installed towards the indoor side. If the air conditioner needs to be turned on for a long time every day in summer, the installation position doesn't matter. After all, it can save energy in winter, and it is easy to consume electricity in summer, there is no need to care about the glass installation position once it is positive and negative.

8. How many kinds of Low-E glass are there? How to choose?

Low-E glass can be divided into high permeability Low-E glass, sunshade Low-E glass and double silver Low-E glass according to its performance and application. Select suitable Low-E glass according to different regions, for example, broken bridge aluminum windows in Beijing and broken bridge aluminum windows in Guangzhou are different in choosing Low-E glass, and different types of glass are selected according to different regions and climate.