Energy-saving doors and windows are a kind of doors and windows to increase the lighting and ventilation area or to show the character characteristics of modern buildings. Energy-saving doors and windows will improve the optical performance, thermal performance and sealing performance of materials, and improve the structure of doors and windows to achieve the expected effect. Energy-saving doors and windows should be considered from the following aspects: first, the material of doors and windows; Second, glass; Third, energy saving of doors and windows is the overall energy saving. In a word, the energy saving of doors and windows depends not only on the material, but also on the glass, and more on the craft of doors and windows.

Judging from the materials of doors and windows, there are some energy-saving products with high technical content, such as aluminum alloy heat-breaking profiles, aluminum-wood composite profiles, steel-plastic integral extrusion profiles and UPVC plastic profiles, among them, UPVC plastic profiles are widely used, and the raw material used is polymer material-hard polyvinyl chloride.

In order to solve the problem of excessive energy loss caused by large-area glass, ordinary glass is processed into insulating glass, coated glass, high-strength LOW-E fireproof glass, the glass containing metal layer and the most special smart glass are plated by Magnetron vacuum sputtering radiation method.

Three properties: watertightness, air tightness, wind pressure resistance heat transfer coefficient is K value, the current standard 2.8 is expected to implement 2.0 energy saving certification in 2006.

When it comes to the energy saving of doors and windows, it is actually the overall energy saving. Relying on glass alone cannot achieve the purpose of energy saving. The sealing performance of doors and windows is also an important parameter affecting energy saving. If there is a problem with the sealing of doors and windows, energy will also be easily lost. The sealing of doors and windows includes the following aspects: firstly, the selection of sealing materials. Good sealing strips are flexible, elastic and weather resistant, and can maintain its toughness even at minus 20℃; secondly, in addition to the sealing strip, doors and windows also need to be processed by special technology, and the noise disturbing the outside world will disappear.

II. Three elements of energy saving for doors and windows

1. Material of doors and windows

Now the materials of doors and windows include aluminum alloy, plastic steel, plastic, solid wood and broken bridge aluminum. There is a common sense that everyone knows that the thermal conductivity of iron and aluminum is very high, and a little heat will be emitted, so the house is always very cold in winter. A few years ago, plastic-steel windows and instrument frame were popular, but the windows made of this material were insufficient rigidity large, which was easy to become brittle and safe. Wooden window has excellent energy saving and environmental protection performance, but wooden window has its own defects, which are easy to burn, rot, crack, etc., and the price of wooden window is also expensive. At present, broken bridge aluminum doors and windows has the best energy saving and environmental protection performance. It not only solves the defect of high thermal conductivity of aluminum alloy, but also makes up for the disadvantage of low strength of plastic steel and plastic, and the price is relatively low compared with solid wood.

2. Glass

Glass occupies most of the area of doors and windows, so it plays a very important role in energy saving index. There are several types of glass on the market: first, ordinary glass, which has not been tempered yet; Second, ordinary tempered glass; Third, coated glass; Fourth, low-e Glass. Each kind of glass can be subdivided. So which glass has the best energy saving effect? It should be low-e Glass, which can filter out harmful light such as infrared ray, far infrared ray and ultraviolet ray, with remarkable energy saving effect. In recent years, the state requires high-rise buildings to adopt hollow glass, which is two layers of glass. However, looking at the insulating glass in the market is specious, it may just be a simple two-layer combination, and the real heat insulation effect has not been achieved.

3. Energy saving of doors and windows is the overall energy saving

When it comes to the energy saving of doors and windows, it is actually the energy saving of the whole window. Relying on glass alone cannot achieve the purpose of energy saving. The sealing performance of doors and windows is also an important parameter affecting energy saving. If there is a problem with the sealing of doors and windows, energy will also be easily lost. The sealing of doors and windows includes the following aspects. The first is the selection of sealing materials. Good sealing strips are flexible and elastic, and have strong weather resistance. Even at minus 20 degrees, they can also maintain their toughness. In addition to the sealing strip, doors and windows also need to be processed by special technology, and the noise disturbing from the outside world will disappear.

All in all, the energy saving of doors and windows depends not only on the material, but also on the glass, but also on the craft of doors and windows!

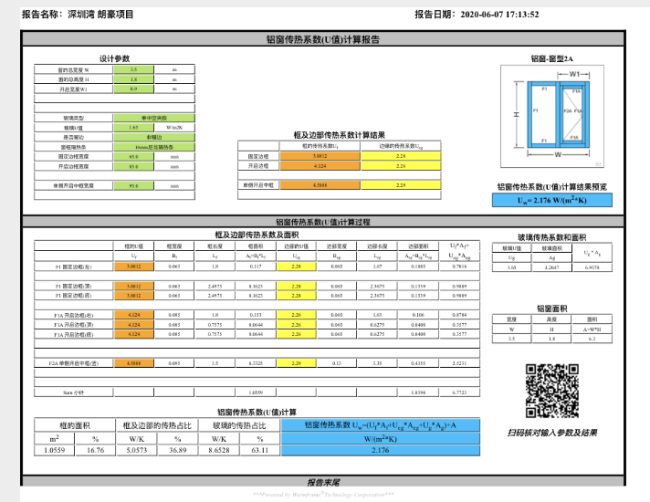

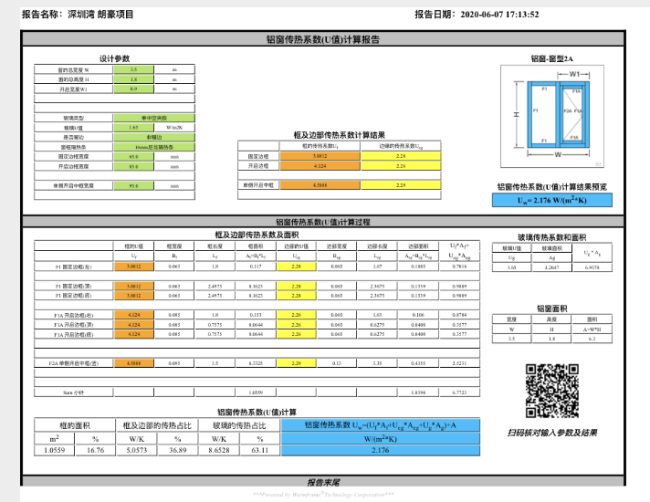

There are many factors that affect the energy saving of doors and windows, which need to be based on Section 4 "thermal calculation of glass curtain wall" in the latest edition of JGJ/T 151-2008 "thermal calculation of building doors and windows and curtain wall", use thermal calculation software to carry out quantitative thermal calculation on all kinds of door and window systems, weigh calculation with window-wall ratio, and compare the influence of various measures and schemes on the energy-saving performance of doors and windows, then compare the cost of each scheme for design optimization, which should be the main principle of energy saving of doors and windows and reducing thermal data design of exterior windows.