Cutting down trees, destroying the environment, and watching modern wood structures realize environmental protection

01

trees-natural carbon captors"

(Photo Source: Canadian wood Association-public number, invasion and deletion)

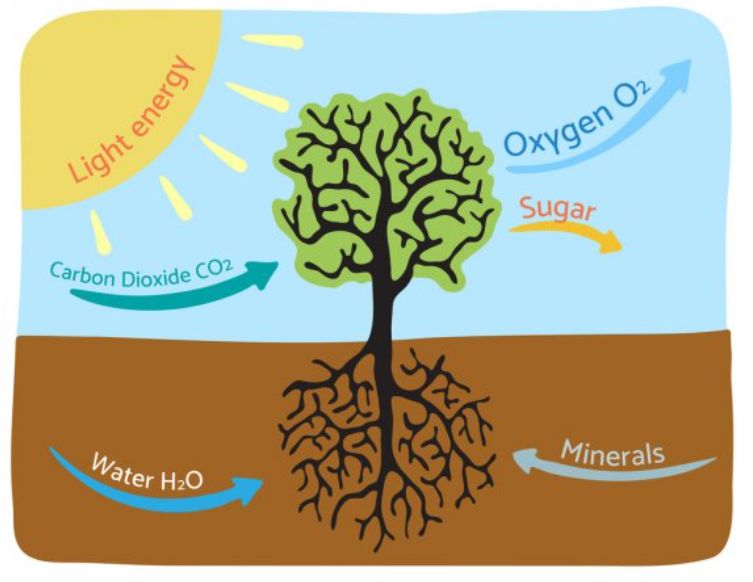

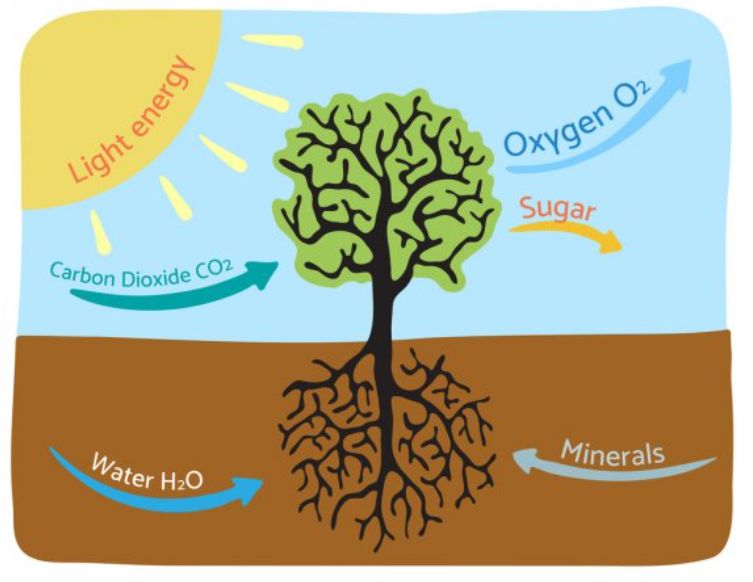

the whole Life of Trees is the process of continuous photosynthesis. Trees use the light energy of the sun to transfer CO in the air? Converted into organic matter fixed in the "body" for their own growth and consumption, while releasing oxygen into the air. In this process, trees absorb a large amount of carbon dioxide and convert carbon dioxide into wood.

(Photo Source: Canadian wood Association-public number, invasion and deletion)

02

cutting trees-one of the best ways to retain carbon

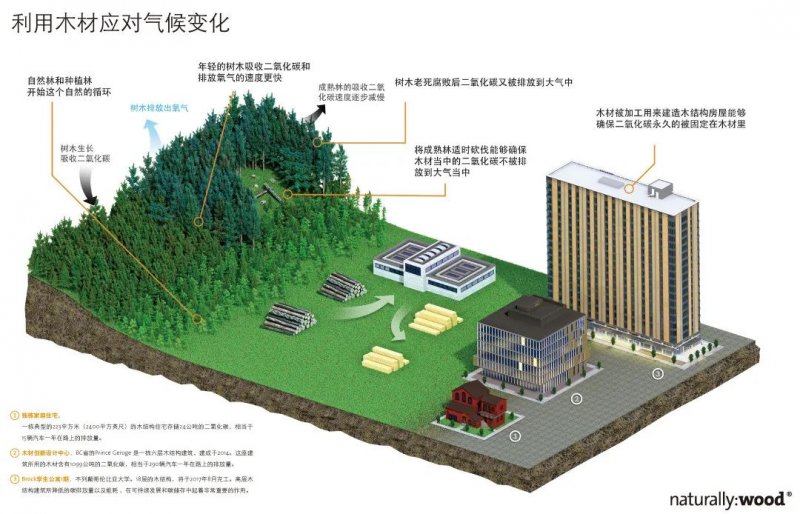

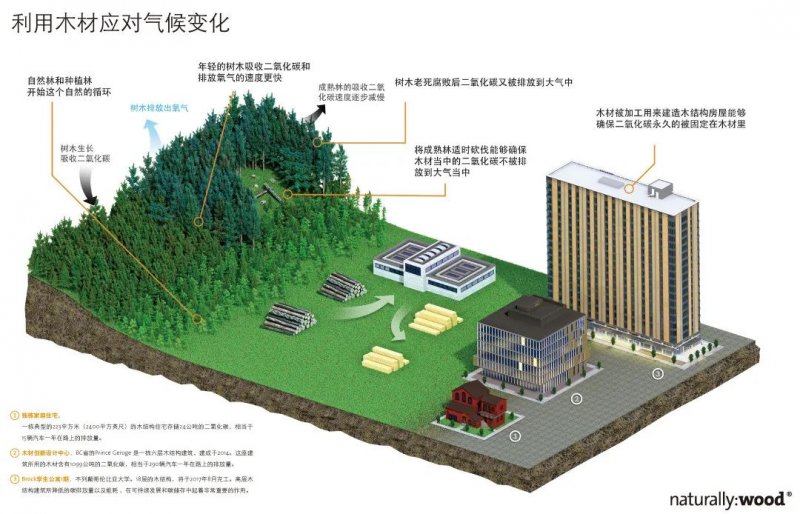

most of the wood used in the building comes from pine. Taking spruce as an example, it takes about 80 years to mature. During these years, it has become the net absorber of carbon. Once mature, they release carbon back to the atmosphere by dropping needles and branches. The forest land covered with pine needle is one of the major hidden dangers of forest fires.

And trees will also die of illness and illness. When they die naturally, the carbon stored in their bodies will be released back into the atmosphere.

Therefore, one of the best forms of carbon storage is to cut trees reasonably and prolong the time of carbon storage.

(Photo Source: Canadian wood Association-public number, invasion and deletion)

03

modern and sustainable forest management methods

(Photo Source: Canadian wood Association-public number, invasion and deletion)

the reason why modern wooden buildings can be vigorously promoted in all countries around the world today is to establish a sustainable forest management system. Take Canada as an example. As a global leader in sustainable forest management, large-scale clearance logging has withdrawn from the historical stage. For each felled tree, the forestry industry will replant it in three times the number. This can not only ensure the diversity of tree species, minimize the negative impact on nature, make the forest more vibrant, improve the wood yield, and the absorption rate of carbon dioxide of newly planted seedlings is much higher than that of adult trees.

Sustainable forest management is not only to retain the number of forests for future generations, but also to protect the biodiversity of forests and create environmental and sustainable congenital conditions for wood production and subsequent utilization. With the efforts of several generations, the current forestry practitioners in Canada have skilled cutting and planting techniques and strong awareness of environmental protection. Moreover, the judicial system, companies and professionals all participate in and are responsible for strict forest management planning and approval procedures, and have a sound supervision, monitoring and law enforcement system. All departments develop together and devote themselves to protecting the environment and improving the education and social development level of the staff.

(Photo Source: Canadian wood Association-public number, invasion and deletion)

04

negative carbon material, carbon reduction building-modern wood structure

production link

(Photo Source: Canadian wood Association-public number, invasion and deletion)

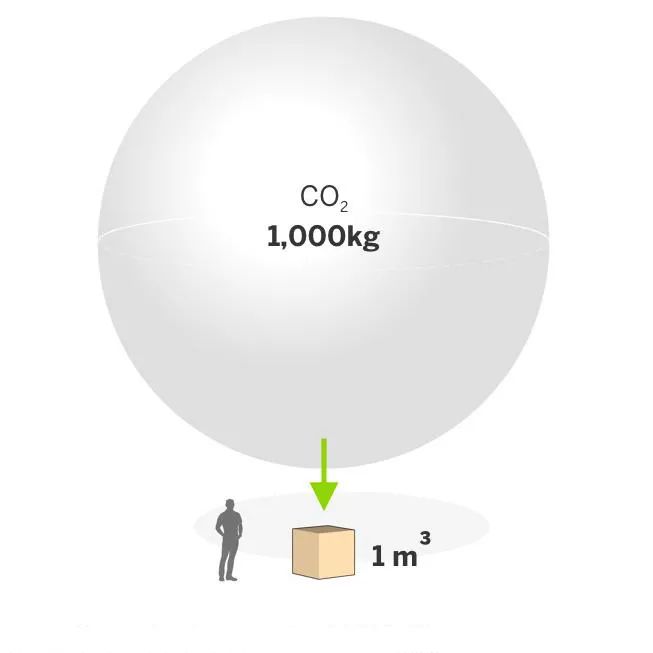

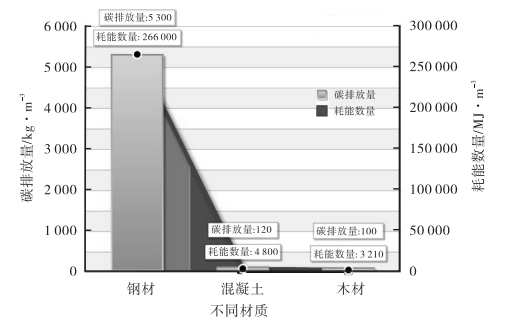

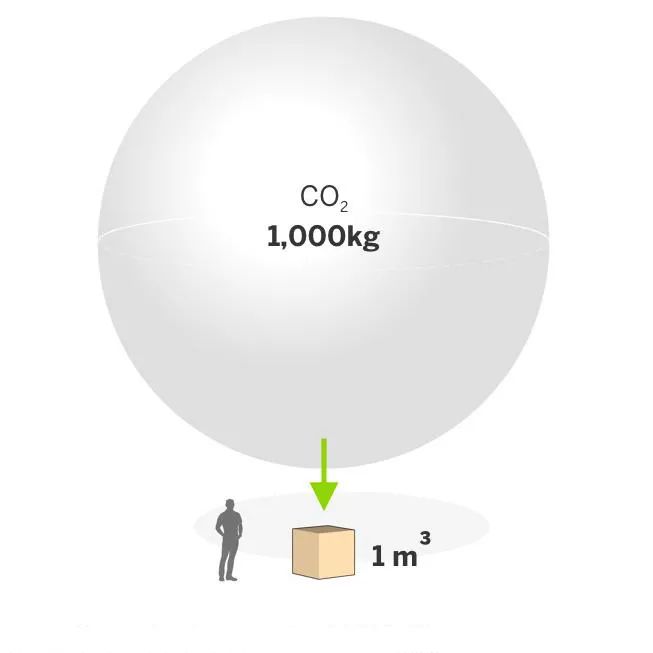

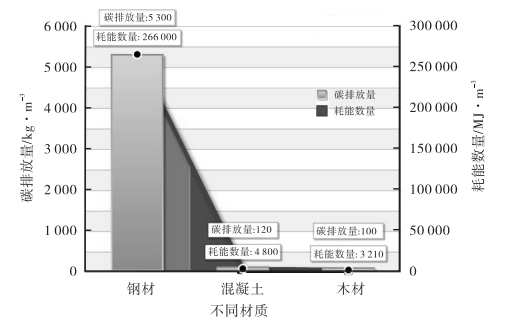

from the perspective of processing, compared with other building materials, wood has the characteristics of low energy consumption and low carbon emissions. From logs to plates, most of the energy consumed comes from by-products in the production process of wood itself. In the process of cutting, transportation and use, the carbon dioxide emitted is far less than the amount of carbon fixation in wood.

(Photo Source: Canadian wood Association-public number, invasion and deletion)

the production of building materials such as steel and cement is relatively dependent on the consumption of external resources, such as smelting and firing, and also releases a large amount of carbon dioxide. Relevant data show that the production of concrete weighing one ton or one cubic meter produces carbon dioxide equivalent to 410 kilograms. Arnim Seidel, a German architect, once said publicly, "building more wooden structures means storing more carbon dioxide and reducing carbon emissions."

less construction waste is generated during construction.

Different from the beam pillar of traditional in-situ processing-structure residential components, modern wood-structure buildings do not need to adopt "wet operation". Through mass processing and production of wooden components, "dry operation" becomes possible.

(Photo Source: Canadian wood Association-public number, invasion and deletion)

△Brock Commons construction site? naturallywood

thanks to the development of wood structure assembly technology, prefabricated components can be installed directly after being transported to the site. Orderly arrangement of wood components can not only avoid chaotic construction sites, but also improve construction efficiency, it can also reduce all kinds of losses in the construction process, and at the same time, dry operation has no dust pollution and no extra construction waste will be generated. In the construction process, low carbon and environmental protection are truly achieved.

Using wood to build is equivalent to storing the carbon captured by trees in buildings. With reasonable design and enclosure, wooden structures can easily reach more than 100 years, which also prolongs the carbon fixation cycle of trees.

Recyclable Wood

as Wood is a natural building material, any wood waste produced in the construction process can be turned into treasure and become a part of ecological circular economy.

Most waste wood can become the raw material of wood industry after being treated, while the remaining waste wood can be used as biomass energy and its calorific value is similar to that of ordinary coal, SO is almost not emitted during combustion? And NO, the impact on the environment is very small. Finally, the burnt ash can become a good fertilizer in agricultural production. The wood has been used to the greatest extent. It can be said that the whole body is full of treasures.

(Photo Source: Canadian wood Association-public number, invasion and deletion)

△Wood chips are used as fuel for biomass boilers to provide heating for ten community buildings

(Photo Source: Canadian wood Association-public number, invasion and deletion)

△ waste timber mill and wood chips from sawdust can be used to make panels, paper, etc.

(Photo Source: Canadian wood Association-public number, invasion and deletion)

△ engineering wood fiber mat that can replace automobile glass fiber parts

forest is the largest carbon pool in the terrestrial ecosystem. Forest vegetation can absorb carbon dioxide in the atmosphere through photosynthesis, play a huge carbon sink function, and has the characteristics of large carbon sink, low cost, high ecological added value, etc. The use of wood, a natural building material, is conducive to alleviating climate change and achieving the goal of carbon neutralization as soon as possible.

(Source: Canadian wood industry association-public number, invasion and deletion)