Recently, at the 29th Shanghai glass exhibition, the vacuum glass displayed by yaopi Glass Group attracted much attention. The so-called vacuum glass is to seal two pieces of flat glass around and place two pieces of glass

recently, at the 29th Shanghai glass exhibition, the vacuum glass displayed by yaopi Glass Group attracted much attention.

The so-called vacuum glass is to seal two pieces of flat glass around and draw air out between the two pieces of glass to make a vacuum space. A closer look shows that ceramic pillars are distributed between the two pieces of vacuum glass to support the whole piece of glass. This is because: the existing technical conditions cannot meet the complete vacuum state between the two pieces of glass, and there must be enough fulcrum to support between the two pieces of glass to further extract air. Therefore, if you look carefully at the vacuum glass in your life, you will see small particles one by one. Don't mistake these small black spots for dirty things!

Vacuum glass, as a new generation of glass products, its technical indicators are comparable to the four-glass three-chamber hollow glass products rarely used on the market. The 0.1-0.2mm vacuum layer technology and special metal film coating technology formed between the two layers of glass achieve the effect of efficient sound insulation and heat insulation although the glass is thin.

The specific advantages of vacuum glass are as follows--

i. Excellent thermal insulation effect

in cold winter, although there is heating, the room is difficult to warm, and the foot of the window is always chilly, which is caused by the low heat insulation performance of the window glass.

The heat insulation effect of vacuum glass applied on doors and windows is about 4 times that of a piece of ordinary veneer glass and 2 times that of ordinary hollow glass. The use of vacuum glass in the living room can ensure the efficient thermal insulation of the room, especially in winter. You can not only open the curtains, let warm sunshine enter the room, but also turn on the heating, let the heating warm the room quickly and maintain warmth for a long time, even if you are at home barefoot, you always feel warm from head to toe!

At present, the heat transfer coefficient of energy-saving walls in cold and cold areas is required to be 0.4-0.6

W(㎡/K). However, ordinary hollow glass can no longer meet the energy saving requirements of buildings in cold and cold areas in our country, and Low-E hollow glass cannot reach the index of heat transfer coefficient less than 1, only vacuum glass can meet the requirements of all energy saving standards in all regions of our country.

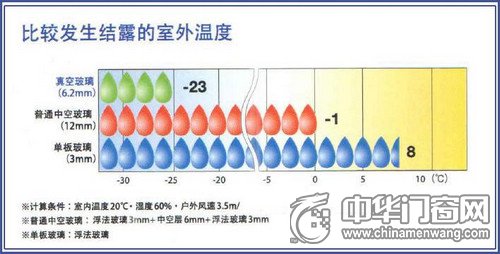

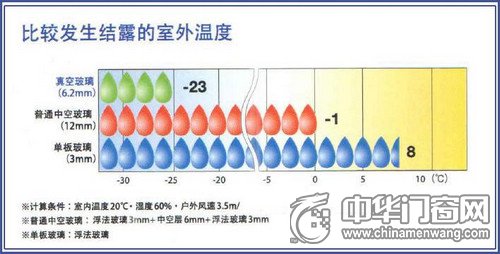

II. Anti-condensation and frost formation performance

although ordinary hollow glass doors and windows have certain energy-saving and heat insulation effects, condensation is especially easy to occur in cold winter and rainy season. It is not only easy to stain curtains and window frames, but also promotes the production of indoor mold. Since there is no gas inside the vacuum glass, the phenomenon of "internal condensation and fog" will not occur, and the thermal resistance of the vacuum glass is relatively high, and its frost-proof performance against external condensation will be correspondingly improved, compared with similar hollow glass, vacuum glass only condenses when the outdoor temperature is lower.

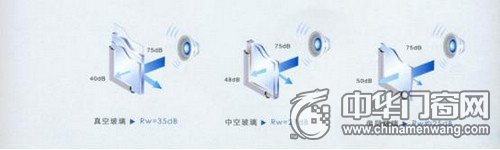

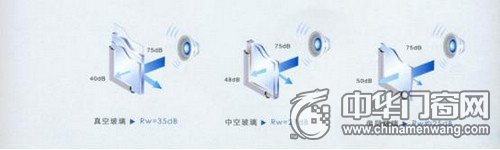

III. Sound insulation performance

because the transmission of sound depends on gas, liquid and solid as the medium, while vacuum glass forms a solid sound transmission structure (acoustic bridge effect) due to a large number of fulcrum between its glass and glass, therefore, the sound insulation capacity is greatly reduced, and there is no resonance generated when two hollow glass vibrates. Therefore, the sound insulation of vacuum glass can generally reach 35 decibels or more, with high-quality sound insulation effect.

In most frequency bands of sound, especially the medium and low frequency bands, the sound insulation performance of vacuum glass is better than that of hollow glass, and the overall sound insulation level is higher than that of hollow glass.

IV. Super composite performance

if vacuum glass is combined with glass deep processing products such as laminated glass, hollow glass, coated glass, fire-proof glass, tempered glass, etc. to form various "Super Glass", there will be various glass doors and windows that can meet customer needs and have different physical properties and good comprehensive properties.

V. Light and thin structure

vacuum glass is lighter and thinner than hollow glass in building doors and windows. In the case that its U value is much better than that of the three-glass and two-chamber hollow glass, the thickness of the vacuum glass is only about one quarter, and at the same time, the weight of the vacuum glass per square meter is reduced by more than 12kg.

VI. Long service life

since the spacer layer of vacuum glass is a sealed vacuum layer made of all glass materials and a long-acting getter is added, vacuum glass itself is a negative pressure device, there is no problem of expanding and cracking when transporting to low pressure areas on the plateau or encountering negative wind pressure, nor does there exist problems of increasing thermal conductivity of hollow glass when installing horizontal and inclination rates, therefore, modern vacuum technology can completely guarantee the vacuum life of vacuum glass for more than 20 years.

The appearance of vacuum glass provides an excellent solution for the realization of "zero energy consumption building" in the future society. Today, when energy conservation and emission reduction are advocated globally, vacuum glass has its unique advantages of super heat insulation, super insulated, anti-condensation, Super sound insulation, super attachment, light structure and long service life, it will be applied and expanded in various industries in the future.