During the production, processing and use of wooden doors, the problem of door leaf deformation is often encountered.

How to effectively avoid the deformation of wooden doors is a topic that everyone cares about.

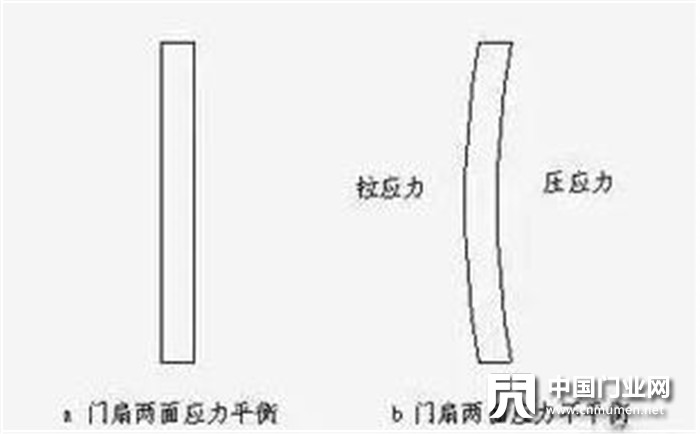

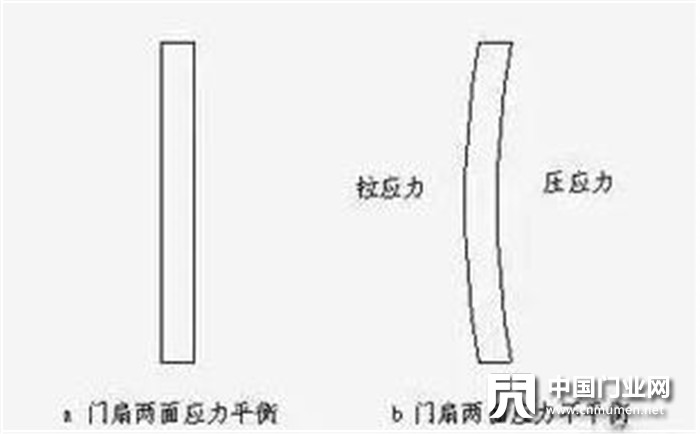

The wooden door is only connected with the door frame by the hinge (or hinge) on the left or right side of the door leaf during use, and the rest is in a free state. The reason for the deformation of wooden door lies in the unbalanced stress on both sides of the door leaf.

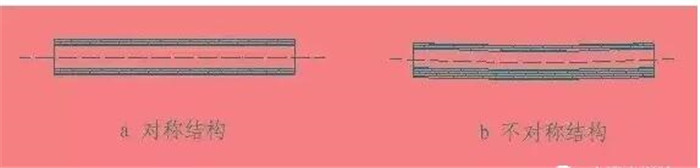

As shown in Figure 1, based on the thickness center of the door leaf, when the stress on both sides of the door leaf is equal, the door leaf is in a straight state;

As shown in Figure 1(a); When the stress on both sides of the door leaf is different, the stress balance is broken, and the bending deformation will occur;

As shown in Figure 1 (B), the bow surface of the door leaf is under tensile stress and the concave surface is under compressive stress.

This kind of stress imbalance is the result of the combined action of many factors, including the reasons of the wooden door itself and the external environment. The main factors leading to the deformation of wooden door leaf include the structure of the product, the materials used, the processing technology of wooden door, the storage, installation and use environment of wooden door, etc.

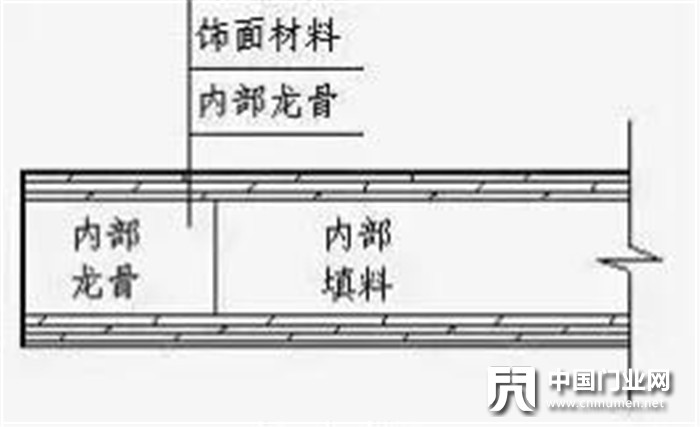

1. Deformation caused by asymmetric product structure

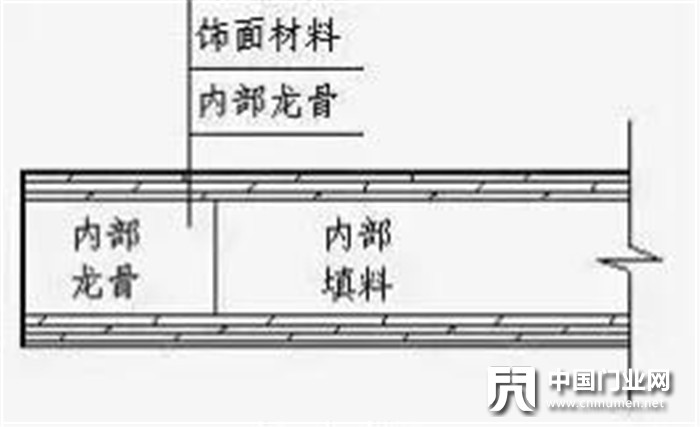

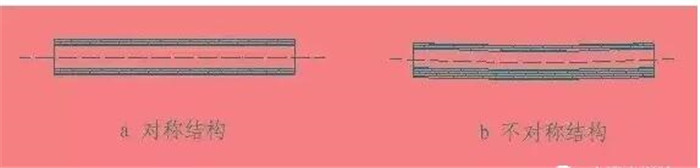

That is, the material characteristics of both sides of the door leaf should be inconsistent. In the case of Fig. 3 (B), due to the different thickness of the facing material, the distance between the adhesive layer on both sides of the door leaf and the center line of the door leaf is inconsistent, although the stress generated by the adhesive during curing process is the same, the door leaf is bent due to the difference of actuating arm.

Therefore, in the production process of products, the thickness, type, moisture content and structure of facing materials must be the same. Some small brand factories use good materials on the front and low-priced materials on the back when processing and manufacturing, which is prone to deformation.

2. Deformation caused by improper material selection

As we all know, Wood is a dry shrinkage and wet expansion material. Within a certain range of moisture content, with the change of moisture content of wood itself, the change of size and shape of wood itself is called the dry shrinkage and wet expansion of wood. This situation also exists in wooden doors made of wood processing. At the same time, Wood is an anisotropic material. The physical and mechanical properties vary greatly in different directions. Closely related to the deformation of the door leaf is the drying shrinkage coefficient of wood, which varies greatly in different directions. The drying shrinkage coefficient of wood is the largest chord, the second is radial, and the smallest is longitudinal. Generally, the chord direction is 1.5 times the radial direction, and the chord direction and radial direction are tens to hundreds of times the longitudinal direction. The dry shrinkage and wet expansion of wood varies with different tree species and density. The dry shrinkage of coniferous wood is smaller than that of broadleaf wood; The soft broadleaf wood is smaller than that of hard broadleaf wood; The greater the density, the greater the dry shrinkage.

The main materials used in the production and processing of wooden doors are wood or man-made Board. In terms of material selection, we should focus on controlling the moisture content of wood and use dried and qualified Wood, this can effectively reduce the dry shrinkage and wet expansion of wood. At the same time, attention should be paid to controlling the moisture content gradient of wood, and there should be no phenomenon that the local moisture content is too high or too low.

Using glued laminated timber as the main internal keel of the door leaf can improve the product's ability to resist external forces. Glued laminated timber, also known as glued wood, is a "V" type mortise and tenon with a certain end surface specification of small Batten (or a narrow and short small Batten), then, apply the adhesive in the mortise and groove for the length direction glue (end splicing), and then assemble the plate with a certain width (horizontal splicing) along the transverse glue, glue in the thickness direction can also be combined as needed. Glued laminated timber does not damage the structure of the wood itself, can maintain the natural texture and texture of the wood, overcome the natural wood is easy to deform, crack, surface defects such as knots, insect attack, tensile and compressive strength is better than wood, good material and high dimensional stability.

3. Deformation caused by unreasonable technology

For example, the door leaf cannot be processed in the next process immediately after the finishing material is pasted. On the one hand, the adhesive is not completely cured; On the other hand, the adhesive contains a large amount of moisture, the moisture does not spread evenly in the glued material. For products processed by hot pressing, the temperature is much higher than the ambient temperature, and subsequent processing needs to be carried out after the product temperature is balanced with the ambient temperature. This balance process is called "Chen Hua" professionally ". After hot pressing, it can be directly stacked and stored for aging. It can also be used to dry the the trigger device, which can reduce the temperature of the door leaf in a short time, achieve the balance between the product and the ambient temperature, and shorten the aging time in the later period.

4. Deformation caused by improper installation

The installation quality of wooden doors directly affects the deformation of wooden doors in use. When the wooden door is installed, the verticality of the door frame and the door leaf must be ensured, so that the center of gravity of the door leaf is on the middle line in the thickness direction of the door leaf, and the opening flexibility must be ensured. In addition, it is recommended to install 3 hinges for each door. The installation position of the hinge is 1/10 of the height of the upper and lower doors, and the Middle hinge is centered on the middle. Compared with the installation of 2 hinges per door, although the cost will increase, it will play a very good role in preventing or reducing the deformation of the door leaf.

5. Deformation caused by improper use

The deformation of wooden door is closely related to its environment. Besides deducting the factors of wooden door itself, the reason for the deformation of wooden door lies in the environmental factors. Because wood itself is easily affected by the surrounding environment, wooden doors made of wood materials are also easily deformed when the environmental conditions (mainly temperature and humidity) change greatly.

For places with relatively bad conditions, such as air ports, wooden doors are prone to deformation during use, and environmental conditions on both sides of the wooden doors should be avoided as much as possible for a long time. Pay special attention to the heating season and the wind season. In the heating season, it should be avoided that the environmental temperature difference between the inside and outside sides of the wooden door caused by heating is too large for a long time, and the environment on one side of the wooden door is too humid.

Editor: China Door Industry Network-dog thief

This kind of stress imbalance is the result of the combined action of many factors, including the reasons of the wooden door itself and the external environment. The main factors leading to the deformation of wooden door leaf include the structure of the product, the materials used, the processing technology of wooden door, the storage, installation and use environment of wooden door, etc.

This kind of stress imbalance is the result of the combined action of many factors, including the reasons of the wooden door itself and the external environment. The main factors leading to the deformation of wooden door leaf include the structure of the product, the materials used, the processing technology of wooden door, the storage, installation and use environment of wooden door, etc.

1. Deformation caused by asymmetric product structure

That is, the material characteristics of both sides of the door leaf should be inconsistent. In the case of Fig. 3 (B), due to the different thickness of the facing material, the distance between the adhesive layer on both sides of the door leaf and the center line of the door leaf is inconsistent, although the stress generated by the adhesive during curing process is the same, the door leaf is bent due to the difference of actuating arm.

Therefore, in the production process of products, the thickness, type, moisture content and structure of facing materials must be the same. Some small brand factories use good materials on the front and low-priced materials on the back when processing and manufacturing, which is prone to deformation.

1. Deformation caused by asymmetric product structure

That is, the material characteristics of both sides of the door leaf should be inconsistent. In the case of Fig. 3 (B), due to the different thickness of the facing material, the distance between the adhesive layer on both sides of the door leaf and the center line of the door leaf is inconsistent, although the stress generated by the adhesive during curing process is the same, the door leaf is bent due to the difference of actuating arm.

Therefore, in the production process of products, the thickness, type, moisture content and structure of facing materials must be the same. Some small brand factories use good materials on the front and low-priced materials on the back when processing and manufacturing, which is prone to deformation.

2. Deformation caused by improper material selection

As we all know, Wood is a dry shrinkage and wet expansion material. Within a certain range of moisture content, with the change of moisture content of wood itself, the change of size and shape of wood itself is called the dry shrinkage and wet expansion of wood. This situation also exists in wooden doors made of wood processing. At the same time, Wood is an anisotropic material. The physical and mechanical properties vary greatly in different directions. Closely related to the deformation of the door leaf is the drying shrinkage coefficient of wood, which varies greatly in different directions. The drying shrinkage coefficient of wood is the largest chord, the second is radial, and the smallest is longitudinal. Generally, the chord direction is 1.5 times the radial direction, and the chord direction and radial direction are tens to hundreds of times the longitudinal direction. The dry shrinkage and wet expansion of wood varies with different tree species and density. The dry shrinkage of coniferous wood is smaller than that of broadleaf wood; The soft broadleaf wood is smaller than that of hard broadleaf wood; The greater the density, the greater the dry shrinkage.

The main materials used in the production and processing of wooden doors are wood or man-made Board. In terms of material selection, we should focus on controlling the moisture content of wood and use dried and qualified Wood, this can effectively reduce the dry shrinkage and wet expansion of wood. At the same time, attention should be paid to controlling the moisture content gradient of wood, and there should be no phenomenon that the local moisture content is too high or too low.

Using glued laminated timber as the main internal keel of the door leaf can improve the product's ability to resist external forces. Glued laminated timber, also known as glued wood, is a "V" type mortise and tenon with a certain end surface specification of small Batten (or a narrow and short small Batten), then, apply the adhesive in the mortise and groove for the length direction glue (end splicing), and then assemble the plate with a certain width (horizontal splicing) along the transverse glue, glue in the thickness direction can also be combined as needed. Glued laminated timber does not damage the structure of the wood itself, can maintain the natural texture and texture of the wood, overcome the natural wood is easy to deform, crack, surface defects such as knots, insect attack, tensile and compressive strength is better than wood, good material and high dimensional stability.

3. Deformation caused by unreasonable technology

For example, the door leaf cannot be processed in the next process immediately after the finishing material is pasted. On the one hand, the adhesive is not completely cured; On the other hand, the adhesive contains a large amount of moisture, the moisture does not spread evenly in the glued material. For products processed by hot pressing, the temperature is much higher than the ambient temperature, and subsequent processing needs to be carried out after the product temperature is balanced with the ambient temperature. This balance process is called "Chen Hua" professionally ". After hot pressing, it can be directly stacked and stored for aging. It can also be used to dry the the trigger device, which can reduce the temperature of the door leaf in a short time, achieve the balance between the product and the ambient temperature, and shorten the aging time in the later period.

4. Deformation caused by improper installation

The installation quality of wooden doors directly affects the deformation of wooden doors in use. When the wooden door is installed, the verticality of the door frame and the door leaf must be ensured, so that the center of gravity of the door leaf is on the middle line in the thickness direction of the door leaf, and the opening flexibility must be ensured. In addition, it is recommended to install 3 hinges for each door. The installation position of the hinge is 1/10 of the height of the upper and lower doors, and the Middle hinge is centered on the middle. Compared with the installation of 2 hinges per door, although the cost will increase, it will play a very good role in preventing or reducing the deformation of the door leaf.

5. Deformation caused by improper use

The deformation of wooden door is closely related to its environment. Besides deducting the factors of wooden door itself, the reason for the deformation of wooden door lies in the environmental factors. Because wood itself is easily affected by the surrounding environment, wooden doors made of wood materials are also easily deformed when the environmental conditions (mainly temperature and humidity) change greatly.

For places with relatively bad conditions, such as air ports, wooden doors are prone to deformation during use, and environmental conditions on both sides of the wooden doors should be avoided as much as possible for a long time. Pay special attention to the heating season and the wind season. In the heating season, it should be avoided that the environmental temperature difference between the inside and outside sides of the wooden door caused by heating is too large for a long time, and the environment on one side of the wooden door is too humid.

Editor: China Door Industry Network-dog thief

2. Deformation caused by improper material selection

As we all know, Wood is a dry shrinkage and wet expansion material. Within a certain range of moisture content, with the change of moisture content of wood itself, the change of size and shape of wood itself is called the dry shrinkage and wet expansion of wood. This situation also exists in wooden doors made of wood processing. At the same time, Wood is an anisotropic material. The physical and mechanical properties vary greatly in different directions. Closely related to the deformation of the door leaf is the drying shrinkage coefficient of wood, which varies greatly in different directions. The drying shrinkage coefficient of wood is the largest chord, the second is radial, and the smallest is longitudinal. Generally, the chord direction is 1.5 times the radial direction, and the chord direction and radial direction are tens to hundreds of times the longitudinal direction. The dry shrinkage and wet expansion of wood varies with different tree species and density. The dry shrinkage of coniferous wood is smaller than that of broadleaf wood; The soft broadleaf wood is smaller than that of hard broadleaf wood; The greater the density, the greater the dry shrinkage.

The main materials used in the production and processing of wooden doors are wood or man-made Board. In terms of material selection, we should focus on controlling the moisture content of wood and use dried and qualified Wood, this can effectively reduce the dry shrinkage and wet expansion of wood. At the same time, attention should be paid to controlling the moisture content gradient of wood, and there should be no phenomenon that the local moisture content is too high or too low.

Using glued laminated timber as the main internal keel of the door leaf can improve the product's ability to resist external forces. Glued laminated timber, also known as glued wood, is a "V" type mortise and tenon with a certain end surface specification of small Batten (or a narrow and short small Batten), then, apply the adhesive in the mortise and groove for the length direction glue (end splicing), and then assemble the plate with a certain width (horizontal splicing) along the transverse glue, glue in the thickness direction can also be combined as needed. Glued laminated timber does not damage the structure of the wood itself, can maintain the natural texture and texture of the wood, overcome the natural wood is easy to deform, crack, surface defects such as knots, insect attack, tensile and compressive strength is better than wood, good material and high dimensional stability.

3. Deformation caused by unreasonable technology

For example, the door leaf cannot be processed in the next process immediately after the finishing material is pasted. On the one hand, the adhesive is not completely cured; On the other hand, the adhesive contains a large amount of moisture, the moisture does not spread evenly in the glued material. For products processed by hot pressing, the temperature is much higher than the ambient temperature, and subsequent processing needs to be carried out after the product temperature is balanced with the ambient temperature. This balance process is called "Chen Hua" professionally ". After hot pressing, it can be directly stacked and stored for aging. It can also be used to dry the the trigger device, which can reduce the temperature of the door leaf in a short time, achieve the balance between the product and the ambient temperature, and shorten the aging time in the later period.

4. Deformation caused by improper installation

The installation quality of wooden doors directly affects the deformation of wooden doors in use. When the wooden door is installed, the verticality of the door frame and the door leaf must be ensured, so that the center of gravity of the door leaf is on the middle line in the thickness direction of the door leaf, and the opening flexibility must be ensured. In addition, it is recommended to install 3 hinges for each door. The installation position of the hinge is 1/10 of the height of the upper and lower doors, and the Middle hinge is centered on the middle. Compared with the installation of 2 hinges per door, although the cost will increase, it will play a very good role in preventing or reducing the deformation of the door leaf.

5. Deformation caused by improper use

The deformation of wooden door is closely related to its environment. Besides deducting the factors of wooden door itself, the reason for the deformation of wooden door lies in the environmental factors. Because wood itself is easily affected by the surrounding environment, wooden doors made of wood materials are also easily deformed when the environmental conditions (mainly temperature and humidity) change greatly.

For places with relatively bad conditions, such as air ports, wooden doors are prone to deformation during use, and environmental conditions on both sides of the wooden doors should be avoided as much as possible for a long time. Pay special attention to the heating season and the wind season. In the heating season, it should be avoided that the environmental temperature difference between the inside and outside sides of the wooden door caused by heating is too large for a long time, and the environment on one side of the wooden door is too humid.

Editor: China Door Industry Network-dog thief