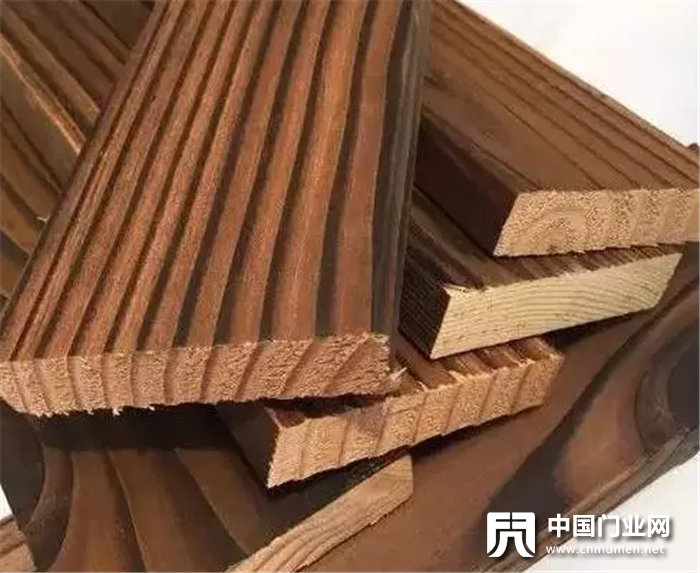

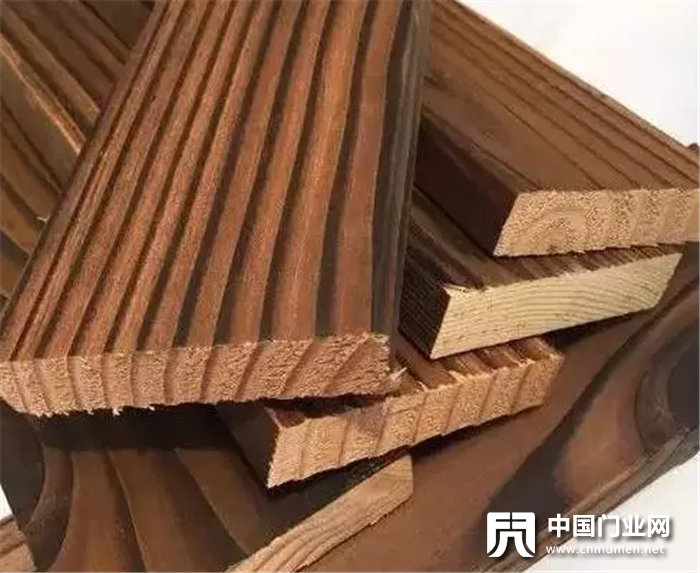

Solid wood composite door is made of natural wood leather, which is actually made of density plate external solid wood leather. Due to the uneven surface of furniture and different shapes, the machine cannot be operated. Therefore, artificial veneer can solve the problem that the machine cannot make complicated modeling.

However, in the process of veneer sticking, we often encounter a problem: manual veneer is easy to blister, and after foaming, the veneer will crack again after ironing the surface of the veneer with an iron. This problem has been bothering many front-line workers all the time, so how to stick solid wood leather without foaming and cracking?

First of all, let's analyze the causes of blister and easy cracking of veneer.

1. Base material bottom uneven

That is, the density plate base material is not polished properly and the surface is uneven.

2. The veneer used is too thick

The veneer used is too thick and does not wet the veneer at the same time. Generally, the thickness of handmade sticker veneer is less than 0.3mm. If it is too thick, it is difficult to use handmade sticker, and it is easy to cause problems.

3. The temperature of the iron is not well controlled.

Generally, if the temperature is too low, it is easy to blister and crack during ironing. In addition to the above problems, it is also related to too high ironing temperature, too frequent ironing times and too short interval.

4. Glue problem

Not up to standard glue is used, resulting in insufficient adhesive force or uneven glue coating. Therefore, choosing high-quality glue is the key to stick the veneer well.

Precautions to prevent skin foaming and cracking:

1. The base material is processed smoothly. It is very important to select a flat substrate without deformation.

2. The wood skin of handmade sticker should be 0.2mm, and should not exceed 0.25mm as far as possible.

3. The temperature of the iron should not be too low. Of course, it should not be too high, and the temperature should be appropriate.

4. The viscosity of the glue should be appropriate, and the solid content should not be too low. Apply glue evenly, pay attention to the quality of glue.

5. The veneer should be soaked, and then dried until the dry humidity is suitable for reuse, but the veneer should not be too wet.

6. Iron the end face or curved surface several times and pay attention to the interval.

7. Try not to cut off the veneer on the end surface with a blade, and use a wooden pad coarse abrasive cloth rubbing off.

Editor: China Door Industry Network-dog thief

2. The veneer used is too thick

The veneer used is too thick and does not wet the veneer at the same time. Generally, the thickness of handmade sticker veneer is less than 0.3mm. If it is too thick, it is difficult to use handmade sticker, and it is easy to cause problems.

2. The veneer used is too thick

The veneer used is too thick and does not wet the veneer at the same time. Generally, the thickness of handmade sticker veneer is less than 0.3mm. If it is too thick, it is difficult to use handmade sticker, and it is easy to cause problems.

3. The temperature of the iron is not well controlled.

Generally, if the temperature is too low, it is easy to blister and crack during ironing. In addition to the above problems, it is also related to too high ironing temperature, too frequent ironing times and too short interval.

4. Glue problem

3. The temperature of the iron is not well controlled.

Generally, if the temperature is too low, it is easy to blister and crack during ironing. In addition to the above problems, it is also related to too high ironing temperature, too frequent ironing times and too short interval.

4. Glue problem

Not up to standard glue is used, resulting in insufficient adhesive force or uneven glue coating. Therefore, choosing high-quality glue is the key to stick the veneer well.

Precautions to prevent skin foaming and cracking:

1. The base material is processed smoothly. It is very important to select a flat substrate without deformation.

2. The wood skin of handmade sticker should be 0.2mm, and should not exceed 0.25mm as far as possible.

3. The temperature of the iron should not be too low. Of course, it should not be too high, and the temperature should be appropriate.

4. The viscosity of the glue should be appropriate, and the solid content should not be too low. Apply glue evenly, pay attention to the quality of glue.

5. The veneer should be soaked, and then dried until the dry humidity is suitable for reuse, but the veneer should not be too wet.

6. Iron the end face or curved surface several times and pay attention to the interval.

7. Try not to cut off the veneer on the end surface with a blade, and use a wooden pad coarse abrasive cloth rubbing off.

Editor: China Door Industry Network-dog thief

Not up to standard glue is used, resulting in insufficient adhesive force or uneven glue coating. Therefore, choosing high-quality glue is the key to stick the veneer well.

Precautions to prevent skin foaming and cracking:

1. The base material is processed smoothly. It is very important to select a flat substrate without deformation.

2. The wood skin of handmade sticker should be 0.2mm, and should not exceed 0.25mm as far as possible.

3. The temperature of the iron should not be too low. Of course, it should not be too high, and the temperature should be appropriate.

4. The viscosity of the glue should be appropriate, and the solid content should not be too low. Apply glue evenly, pay attention to the quality of glue.

5. The veneer should be soaked, and then dried until the dry humidity is suitable for reuse, but the veneer should not be too wet.

6. Iron the end face or curved surface several times and pay attention to the interval.

7. Try not to cut off the veneer on the end surface with a blade, and use a wooden pad coarse abrasive cloth rubbing off.

Editor: China Door Industry Network-dog thief