At present, the setting angle of aluminum alloy doors and windows in China adopts the combination of angle squeezing machine extrusion aluminium profile materials bottom surface and angle code. The working principle of this angle setting method is unscientific. When the angle squeezing knife of the angle squeezing machine is pushed into the surface of the aluminum profile, the resistance strength of the aluminum profile encountered by the two angle squeezing knives during the jacking process is different, the progress of jacking cannot be consistent, and the failure stress of the angle squeezing knife on the aluminum profile cannot be restricted, resulting in local distortion of the shape of the aluminum profile and affecting the quality of the angle setting.

In Europe, the angle of aluminum alloy doors and windows adopts the angle setting method of movable angle code, and its advantages are as follows:

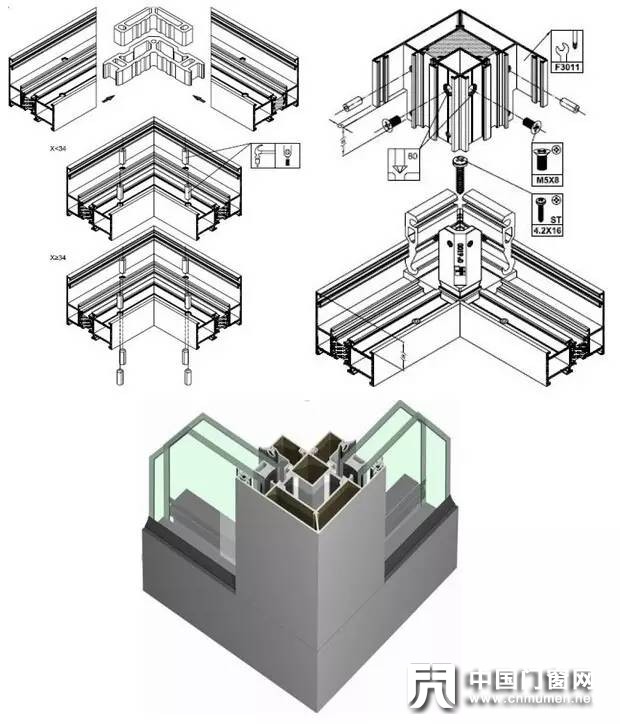

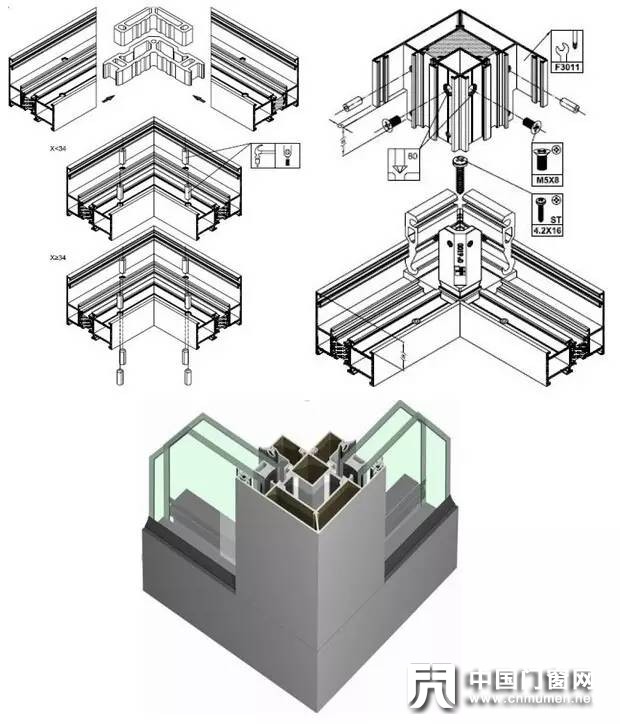

1. The corner connector (movable angle code) is connected by high-strength connecting bolts, and the movable angle code does not damage the chamber of the aluminum profile in the way of squeezing angle unit angle (the external dimension does not distort) the problem of angle 4 offset is avoided. Each worker can Group boxes from 15 to 25 per hour.

2. Angle connector (movable angle code) has passed the "L" shape single angle stress test (can reach more than 35000 Newton), which is more than squeezing angle code (about 1800~2000 Newton) more than 20 times larger (due to the unreasonable connection structure, when the angle strength test is conducted, when the external pressure acts on the test angle, the extruded outer skin of the aluminum alloy profile is affected by the external force, gradually flatten the final angle code and break away; However, due to the reasonable connection structure, the pressure of the active angle code is directly transmitted to the active angle code itself during the test, and it will not be damaged until the active angle code completely destroys the test angle).

3. The biggest advantage is that when there is dislocation in the corner set, you can loosen it and adjust it again. This is incomparable to ordinary angle-squeezing angle codes!

4. The movable angle code can realize the on-site assembly of doors and windows. The aluminum alloy door and window factory in Europe can do the Asian door and window engineering is guaranteed by the characteristic of the movable angle code, after receiving the order, the factory cut the aluminum alloy profile and rushed out the mounting hole of the movable angle code, directly packed it, and directly shipped it to the site for assembly with movable angle code, door and window hardware, etc.

5. Comprehensive Cost performance: Although the price of the movable angle code is slightly higher than that of the squeezing angle code, the work efficiency is 5 to 8 times that of the squeezing angle unit angle (5 yuan/per hour/per person); the meter weight of the extruded angle code is about 2.0~3.2 kg/m, but due to the unreasonable angle setting method, the angle strength cannot be proportional to the weight of the extruded angle code.

6. Profile cost: due to the advanced principle of movable angle code connection, its corner strength is realized by structure, with small aluminum content and small profile chamber requirements (thickness 14mm) compared with the traditional extrusion angle code (thickness is about 20mm), the standard window material consumption of the profile using the movable angle code can save 10% ~ 15% of the aluminum consumption of the profile.

In Europe, the angle of aluminum alloy doors and windows adopts the angle setting method of movable angle code, and its advantages are as follows:

1. The corner connector (movable angle code) is connected by high-strength connecting bolts, and the movable angle code does not damage the chamber of the aluminum profile in the way of squeezing angle unit angle (the external dimension does not distort) the problem of angle 4 offset is avoided. Each worker can Group boxes from 15 to 25 per hour.

2. Angle connector (movable angle code) has passed the "L" shape single angle stress test (can reach more than 35000 Newton), which is more than squeezing angle code (about 1800~2000 Newton) more than 20 times larger (due to the unreasonable connection structure, when the angle strength test is conducted, when the external pressure acts on the test angle, the extruded outer skin of the aluminum alloy profile is affected by the external force, gradually flatten the final angle code and break away; However, due to the reasonable connection structure, the pressure of the active angle code is directly transmitted to the active angle code itself during the test, and it will not be damaged until the active angle code completely destroys the test angle).

In Europe, the angle of aluminum alloy doors and windows adopts the angle setting method of movable angle code, and its advantages are as follows:

1. The corner connector (movable angle code) is connected by high-strength connecting bolts, and the movable angle code does not damage the chamber of the aluminum profile in the way of squeezing angle unit angle (the external dimension does not distort) the problem of angle 4 offset is avoided. Each worker can Group boxes from 15 to 25 per hour.

2. Angle connector (movable angle code) has passed the "L" shape single angle stress test (can reach more than 35000 Newton), which is more than squeezing angle code (about 1800~2000 Newton) more than 20 times larger (due to the unreasonable connection structure, when the angle strength test is conducted, when the external pressure acts on the test angle, the extruded outer skin of the aluminum alloy profile is affected by the external force, gradually flatten the final angle code and break away; However, due to the reasonable connection structure, the pressure of the active angle code is directly transmitted to the active angle code itself during the test, and it will not be damaged until the active angle code completely destroys the test angle).

3. The biggest advantage is that when there is dislocation in the corner set, you can loosen it and adjust it again. This is incomparable to ordinary angle-squeezing angle codes!

4. The movable angle code can realize the on-site assembly of doors and windows. The aluminum alloy door and window factory in Europe can do the Asian door and window engineering is guaranteed by the characteristic of the movable angle code, after receiving the order, the factory cut the aluminum alloy profile and rushed out the mounting hole of the movable angle code, directly packed it, and directly shipped it to the site for assembly with movable angle code, door and window hardware, etc.

5. Comprehensive Cost performance: Although the price of the movable angle code is slightly higher than that of the squeezing angle code, the work efficiency is 5 to 8 times that of the squeezing angle unit angle (5 yuan/per hour/per person); the meter weight of the extruded angle code is about 2.0~3.2 kg/m, but due to the unreasonable angle setting method, the angle strength cannot be proportional to the weight of the extruded angle code.

6. Profile cost: due to the advanced principle of movable angle code connection, its corner strength is realized by structure, with small aluminum content and small profile chamber requirements (thickness 14mm) compared with the traditional extrusion angle code (thickness is about 20mm), the standard window material consumption of the profile using the movable angle code can save 10% ~ 15% of the aluminum consumption of the profile.

3. The biggest advantage is that when there is dislocation in the corner set, you can loosen it and adjust it again. This is incomparable to ordinary angle-squeezing angle codes!

4. The movable angle code can realize the on-site assembly of doors and windows. The aluminum alloy door and window factory in Europe can do the Asian door and window engineering is guaranteed by the characteristic of the movable angle code, after receiving the order, the factory cut the aluminum alloy profile and rushed out the mounting hole of the movable angle code, directly packed it, and directly shipped it to the site for assembly with movable angle code, door and window hardware, etc.

5. Comprehensive Cost performance: Although the price of the movable angle code is slightly higher than that of the squeezing angle code, the work efficiency is 5 to 8 times that of the squeezing angle unit angle (5 yuan/per hour/per person); the meter weight of the extruded angle code is about 2.0~3.2 kg/m, but due to the unreasonable angle setting method, the angle strength cannot be proportional to the weight of the extruded angle code.

6. Profile cost: due to the advanced principle of movable angle code connection, its corner strength is realized by structure, with small aluminum content and small profile chamber requirements (thickness 14mm) compared with the traditional extrusion angle code (thickness is about 20mm), the standard window material consumption of the profile using the movable angle code can save 10% ~ 15% of the aluminum consumption of the profile.