Energy-saving thermal insulation doors and windows are a perfect combination of systems. The comprehensive results of each link performance are indispensable. Three factors should be considered to measure whether building doors and windows are energy-saving, namely heat loss (heat exchange), convection of heat and conduction and radiation of heat.

1. Convection is the circulation flow of hot and cold air through the gap between doors and windows, and heat exchange is made through gaseous exchange, resulting in heat loss;

2. Heat conduction is the heat transfer by the molecular movement of the materials used by doors and windows, which is transferred to the other side through one side of the material itself, resulting in heat loss;

3. Radiation is mainly transmitted directly in the form of radiation, resulting in loss of energy consumption.

From the perspective of three elements, we should pay attention to the following aspects for energy-saving doors and windows:

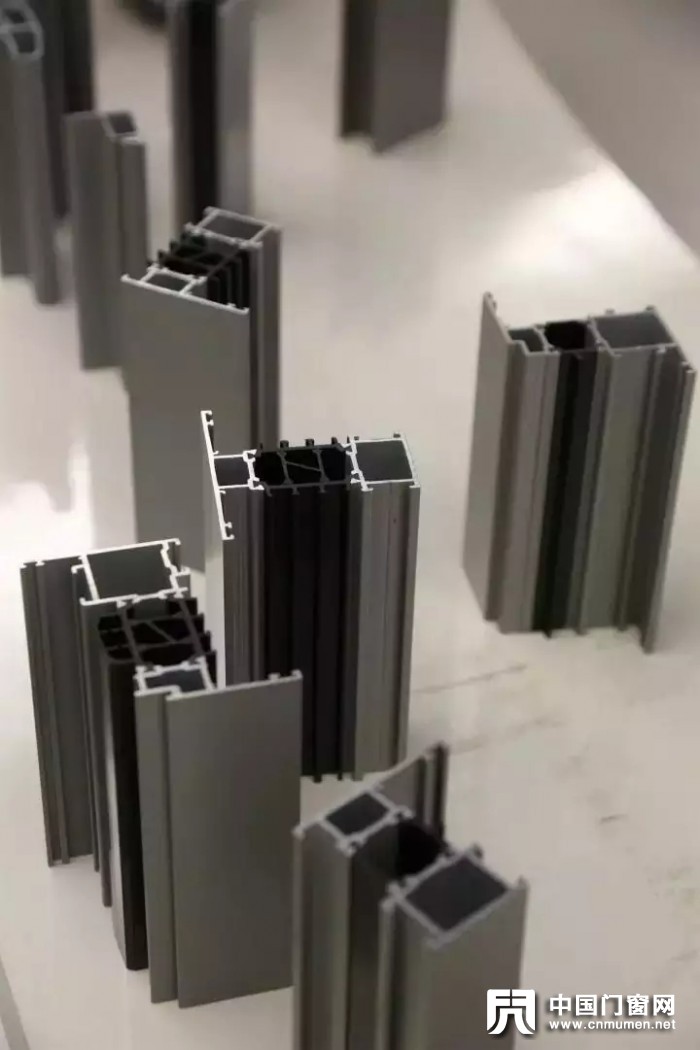

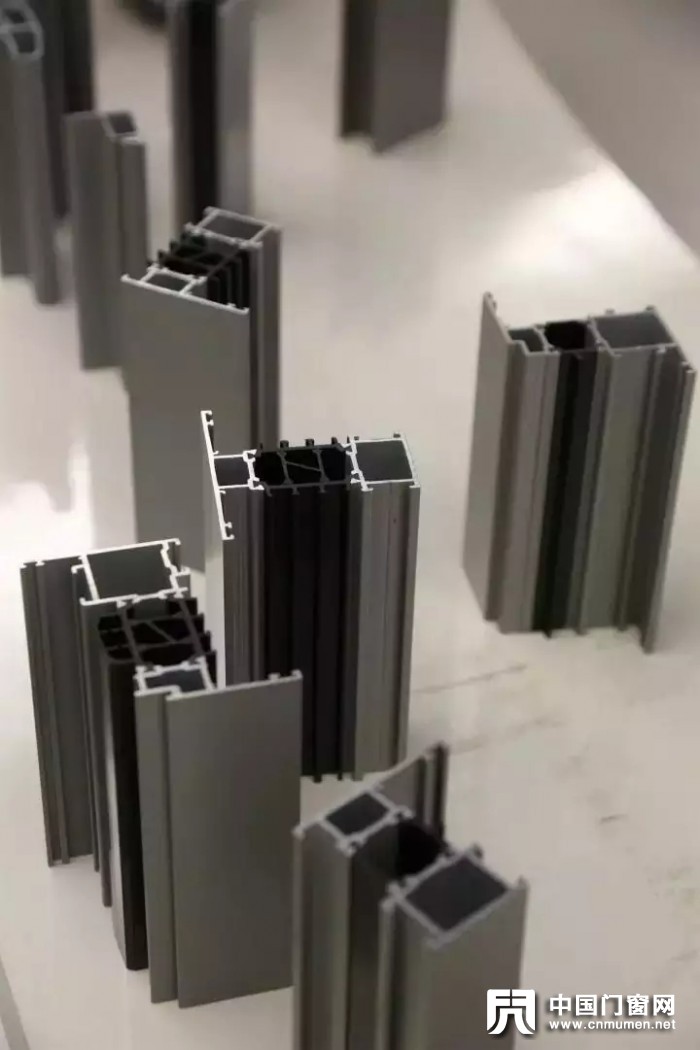

i. Design and selection of profiles

first of all, choose profiles of different materials. Their performance is different, mainly because different heat-conduction coefficient determines the energy consumption of doors and windows. When you choose a material, it is very important to design the profile section. Take aluminum alloy profiles to discuss: now there are construction units in most areas that only consider the cost and do not pay attention to performance in the selection of profiles.

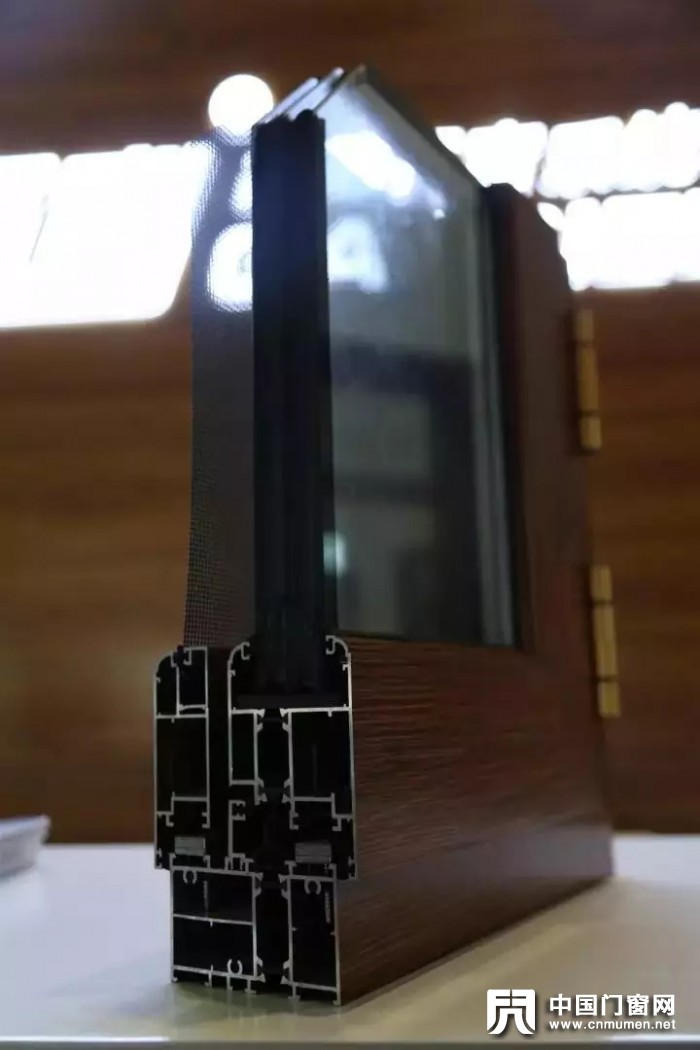

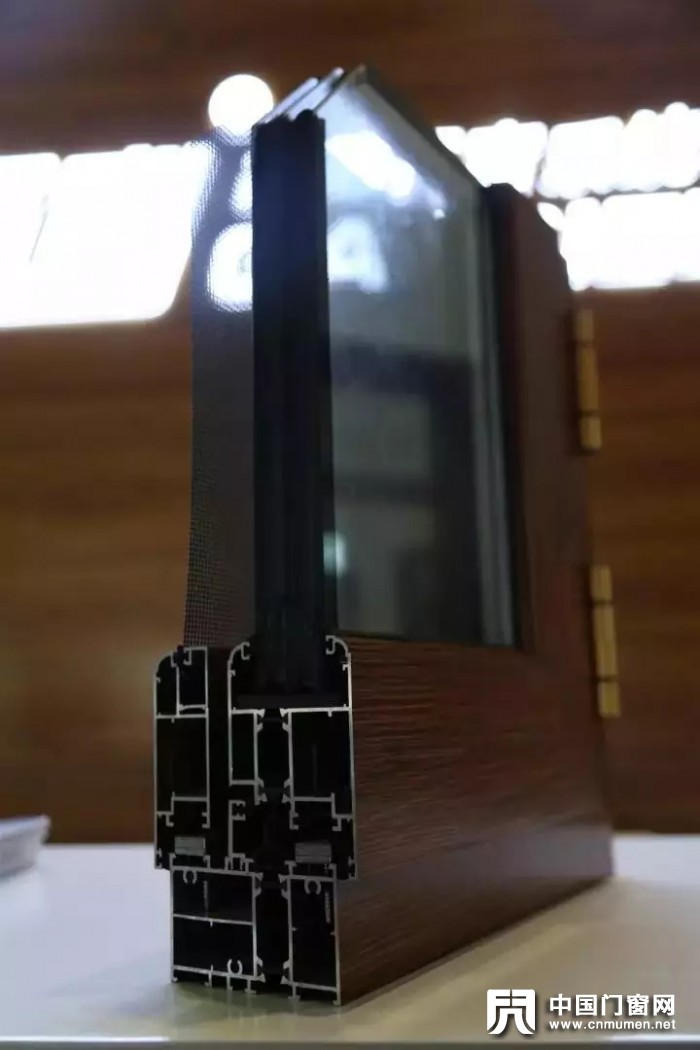

In order to avoid the shortage of aluminum alloy itself, the multi-cavity aluminum alloy profile of heat insulation cold Bridge was developed. The way of heat insulation and cold bridge prevents the rapid heat conduction of aluminum alloy profiles, thus realizing energy saving. The design of aluminum profiles that can be insulated and broken bridges often ignores details.

The heat insulation strips on the frame and fan material are not on the same side (by outdoor or indoor), so that after the hardware accessories are installed, the indoor and outdoor profiles are connected to each other through metal hardware accessories bypassing the heat insulation strips, thus making the heat transfer quickly, affect the energy saving performance of doors and windows, etc.

Of course, whether the improvement of profiles can achieve energy saving effect on the whole window is also related to the choice of window opening form, such as flat doors and windows, and the energy saving effect of adopting insulated Bridge aluminum alloy profiles is obvious.

For sliding doors and windows, the use of heat insulation broken bridge aluminum profiles can only be said to be difficult to sound alone. Due to the structural form of sliding doors and windows, the two casement are not in the same plane when they are closed, however, there is no sealing pressure between the two casement and around them, only relying on wool tops to overlap and overlap, and there is a gap between the wool tops, forming convection phenomenon.

Experts once analyzed the heat transfer coefficient and heat consumption ratio of various components of basic buildings in Beijing. One of the contents is that the energy consumption of air infiltration accounts for of the whole, however, the energy consumption of air infiltration is mainly lost through the gap between doors and windows.

It can be imagined that if sliding doors and windows are adopted, the energy loss caused by air penetration will be more serious. Therefore, even if sliding doors and windows use heat insulation broken bridge aluminum profiles, they are not energy-saving doors and windows. Due to the limitation of sliding window's own structure, it is meaningless to use heat insulation broken bridge aluminum profiles.

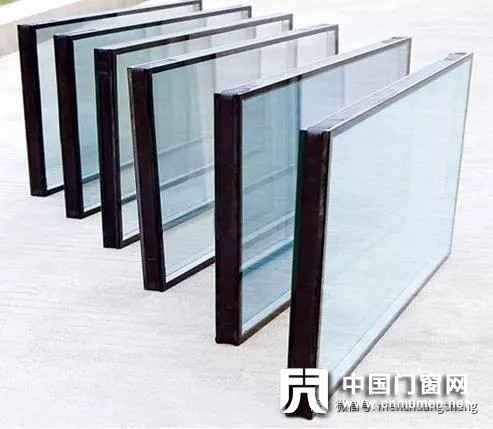

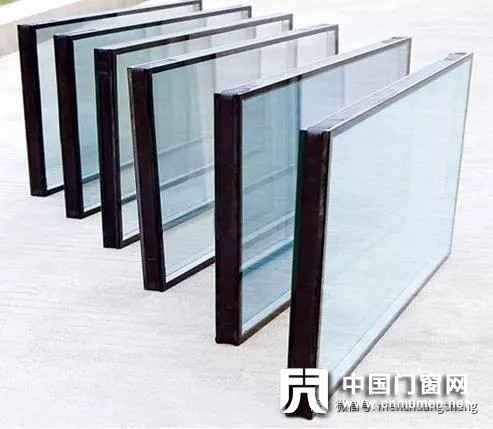

Second, the choice of glass

the use of glass for building doors and windows is relatively mature in our country. Glass with different properties can be selected according to different energy saving indexes in different regions to meet the requirements of energy saving. We know that energy loss is mainly caused by convection, conduction and radiation.

While glass is mainly heat radiation energy loss, so when we choose the glass of building doors and windows, to ensure the energy saving of the whole building, we have to choose glass reasonably to meet the needs of different buildings in different places, select glass with corresponding heat transfer coefficient and shading coefficient.

3. Accessories

"Hardware accessories are the heart of doors and windows, not supporting angles". Hardware accessories play a very important role in energy-saving doors and windows. They are not only closely related to the air tightness, water tightness and wind pressure resistance of doors and windows, but also play a very important role in safety and other performance. Energy-saving doors and windows hardware accessories should take into account the following aspects:

selection of hardware accessories material selection hardware accessories with good materials are the basic guarantee of good quality energy-saving doors and windows. Hardware accessories with poor materials are easy to age and crack. In this way, doors and windows can not be opened flexibly or can not be opened or closed. This will not only ensure the air tightness and energy saving of building doors and windows, but also bring harm to people's life safety.

Therefore, when choosing hardware accessories, we must choose brand products with quality assurance, and we cannot covet cheap products to make small losses.

Reasonable configuration and design of hardware accessories for energy-saving doors and windows above the configuration of hardware accessories for energy-saving doors and windows, a well-locked multi-point locking system should be selected to ensure that the doors are deformed and synchronized under the action of wind pressure, effectively ensure the reasonable cooperation of sealing materials, so that the sealing strip can keep good sealing performance under the strong state of pressure at any time.

You cannot choose cheap and simple single-point lock hardware configuration, because when single-point lock hardware configuration, when doors and windows are under positive wind pressure or negative wind pressure, doors and windows will be deformed without locking points. However, it cannot be homing after deformation, resulting in gaps between fans and frames, making hot and cold air circulate through the gaps between doors and windows, forming convection, which cannot save energy for doors and windows.

IV. Correct assembly

the previous points are the requirements of door and window components, but reasonable selection of components is very important, and the correct combination of various components into a system is a perfect energy-saving door and window, therefore, when we choose door and window assembly plants, it is also crucial to choose powerful and experienced door and window assembly plants.

Judging from the three elements of measuring building doors and windows, sliding doors and windows are not in the same plane when they are closed due to structural reasons, while there is no sealing pressure between the two casement and around them, just rely on wool tops to overlap, and there is a gap between wool tops, forming convection phenomenon, so sliding doors and windows are not energy-saving windows.

Are other open doors and windows energy-saving doors and windows? Other open forms of doors and windows also need comprehensive consideration and reasonable design to meet the requirements of energy saving of doors and windows. But only using energy-saving profiles or energy-saving glass is energy-saving doors and windows? From the above analysis, it is not enough to use only good profiles or glass and accessories for energy-saving doors and windows. The perfect combination of good materials is the element of systematic comprehensive evaluation.

1. Convection is the circulation flow of hot and cold air through the gap between doors and windows, and heat exchange is made through gaseous exchange, resulting in heat loss;

2. Heat conduction is the heat transfer by the molecular movement of the materials used by doors and windows, which is transferred to the other side through one side of the material itself, resulting in heat loss;

3. Radiation is mainly transmitted directly in the form of radiation, resulting in loss of energy consumption.

From the perspective of three elements, we should pay attention to the following aspects for energy-saving doors and windows:

i. Design and selection of profiles

first of all, choose profiles of different materials. Their performance is different, mainly because different heat-conduction coefficient determines the energy consumption of doors and windows. When you choose a material, it is very important to design the profile section. Take aluminum alloy profiles to discuss: now there are construction units in most areas that only consider the cost and do not pay attention to performance in the selection of profiles.

In order to avoid the shortage of aluminum alloy itself, the multi-cavity aluminum alloy profile of heat insulation cold Bridge was developed. The way of heat insulation and cold bridge prevents the rapid heat conduction of aluminum alloy profiles, thus realizing energy saving. The design of aluminum profiles that can be insulated and broken bridges often ignores details.

The heat insulation strips on the frame and fan material are not on the same side (by outdoor or indoor), so that after the hardware accessories are installed, the indoor and outdoor profiles are connected to each other through metal hardware accessories bypassing the heat insulation strips, thus making the heat transfer quickly, affect the energy saving performance of doors and windows, etc.

1. Convection is the circulation flow of hot and cold air through the gap between doors and windows, and heat exchange is made through gaseous exchange, resulting in heat loss;

2. Heat conduction is the heat transfer by the molecular movement of the materials used by doors and windows, which is transferred to the other side through one side of the material itself, resulting in heat loss;

3. Radiation is mainly transmitted directly in the form of radiation, resulting in loss of energy consumption.

From the perspective of three elements, we should pay attention to the following aspects for energy-saving doors and windows:

i. Design and selection of profiles

first of all, choose profiles of different materials. Their performance is different, mainly because different heat-conduction coefficient determines the energy consumption of doors and windows. When you choose a material, it is very important to design the profile section. Take aluminum alloy profiles to discuss: now there are construction units in most areas that only consider the cost and do not pay attention to performance in the selection of profiles.

In order to avoid the shortage of aluminum alloy itself, the multi-cavity aluminum alloy profile of heat insulation cold Bridge was developed. The way of heat insulation and cold bridge prevents the rapid heat conduction of aluminum alloy profiles, thus realizing energy saving. The design of aluminum profiles that can be insulated and broken bridges often ignores details.

The heat insulation strips on the frame and fan material are not on the same side (by outdoor or indoor), so that after the hardware accessories are installed, the indoor and outdoor profiles are connected to each other through metal hardware accessories bypassing the heat insulation strips, thus making the heat transfer quickly, affect the energy saving performance of doors and windows, etc.

Of course, whether the improvement of profiles can achieve energy saving effect on the whole window is also related to the choice of window opening form, such as flat doors and windows, and the energy saving effect of adopting insulated Bridge aluminum alloy profiles is obvious.

For sliding doors and windows, the use of heat insulation broken bridge aluminum profiles can only be said to be difficult to sound alone. Due to the structural form of sliding doors and windows, the two casement are not in the same plane when they are closed, however, there is no sealing pressure between the two casement and around them, only relying on wool tops to overlap and overlap, and there is a gap between the wool tops, forming convection phenomenon.

Experts once analyzed the heat transfer coefficient and heat consumption ratio of various components of basic buildings in Beijing. One of the contents is that the energy consumption of air infiltration accounts for of the whole, however, the energy consumption of air infiltration is mainly lost through the gap between doors and windows.

It can be imagined that if sliding doors and windows are adopted, the energy loss caused by air penetration will be more serious. Therefore, even if sliding doors and windows use heat insulation broken bridge aluminum profiles, they are not energy-saving doors and windows. Due to the limitation of sliding window's own structure, it is meaningless to use heat insulation broken bridge aluminum profiles.

Of course, whether the improvement of profiles can achieve energy saving effect on the whole window is also related to the choice of window opening form, such as flat doors and windows, and the energy saving effect of adopting insulated Bridge aluminum alloy profiles is obvious.

For sliding doors and windows, the use of heat insulation broken bridge aluminum profiles can only be said to be difficult to sound alone. Due to the structural form of sliding doors and windows, the two casement are not in the same plane when they are closed, however, there is no sealing pressure between the two casement and around them, only relying on wool tops to overlap and overlap, and there is a gap between the wool tops, forming convection phenomenon.

Experts once analyzed the heat transfer coefficient and heat consumption ratio of various components of basic buildings in Beijing. One of the contents is that the energy consumption of air infiltration accounts for of the whole, however, the energy consumption of air infiltration is mainly lost through the gap between doors and windows.

It can be imagined that if sliding doors and windows are adopted, the energy loss caused by air penetration will be more serious. Therefore, even if sliding doors and windows use heat insulation broken bridge aluminum profiles, they are not energy-saving doors and windows. Due to the limitation of sliding window's own structure, it is meaningless to use heat insulation broken bridge aluminum profiles.

Second, the choice of glass

the use of glass for building doors and windows is relatively mature in our country. Glass with different properties can be selected according to different energy saving indexes in different regions to meet the requirements of energy saving. We know that energy loss is mainly caused by convection, conduction and radiation.

While glass is mainly heat radiation energy loss, so when we choose the glass of building doors and windows, to ensure the energy saving of the whole building, we have to choose glass reasonably to meet the needs of different buildings in different places, select glass with corresponding heat transfer coefficient and shading coefficient.

Second, the choice of glass

the use of glass for building doors and windows is relatively mature in our country. Glass with different properties can be selected according to different energy saving indexes in different regions to meet the requirements of energy saving. We know that energy loss is mainly caused by convection, conduction and radiation.

While glass is mainly heat radiation energy loss, so when we choose the glass of building doors and windows, to ensure the energy saving of the whole building, we have to choose glass reasonably to meet the needs of different buildings in different places, select glass with corresponding heat transfer coefficient and shading coefficient.

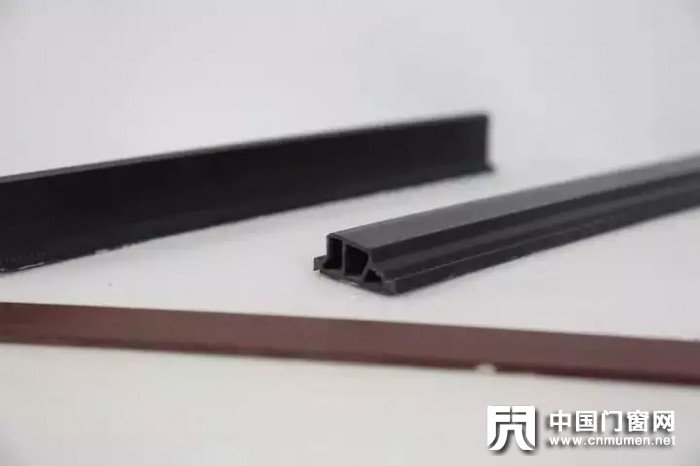

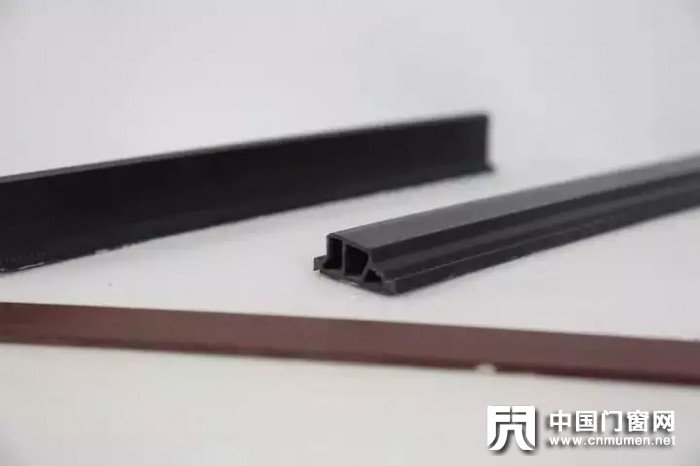

3. Accessories

"Hardware accessories are the heart of doors and windows, not supporting angles". Hardware accessories play a very important role in energy-saving doors and windows. They are not only closely related to the air tightness, water tightness and wind pressure resistance of doors and windows, but also play a very important role in safety and other performance. Energy-saving doors and windows hardware accessories should take into account the following aspects:

selection of hardware accessories material selection hardware accessories with good materials are the basic guarantee of good quality energy-saving doors and windows. Hardware accessories with poor materials are easy to age and crack. In this way, doors and windows can not be opened flexibly or can not be opened or closed. This will not only ensure the air tightness and energy saving of building doors and windows, but also bring harm to people's life safety.

Therefore, when choosing hardware accessories, we must choose brand products with quality assurance, and we cannot covet cheap products to make small losses.

Reasonable configuration and design of hardware accessories for energy-saving doors and windows above the configuration of hardware accessories for energy-saving doors and windows, a well-locked multi-point locking system should be selected to ensure that the doors are deformed and synchronized under the action of wind pressure, effectively ensure the reasonable cooperation of sealing materials, so that the sealing strip can keep good sealing performance under the strong state of pressure at any time.

You cannot choose cheap and simple single-point lock hardware configuration, because when single-point lock hardware configuration, when doors and windows are under positive wind pressure or negative wind pressure, doors and windows will be deformed without locking points. However, it cannot be homing after deformation, resulting in gaps between fans and frames, making hot and cold air circulate through the gaps between doors and windows, forming convection, which cannot save energy for doors and windows.

3. Accessories

"Hardware accessories are the heart of doors and windows, not supporting angles". Hardware accessories play a very important role in energy-saving doors and windows. They are not only closely related to the air tightness, water tightness and wind pressure resistance of doors and windows, but also play a very important role in safety and other performance. Energy-saving doors and windows hardware accessories should take into account the following aspects:

selection of hardware accessories material selection hardware accessories with good materials are the basic guarantee of good quality energy-saving doors and windows. Hardware accessories with poor materials are easy to age and crack. In this way, doors and windows can not be opened flexibly or can not be opened or closed. This will not only ensure the air tightness and energy saving of building doors and windows, but also bring harm to people's life safety.

Therefore, when choosing hardware accessories, we must choose brand products with quality assurance, and we cannot covet cheap products to make small losses.

Reasonable configuration and design of hardware accessories for energy-saving doors and windows above the configuration of hardware accessories for energy-saving doors and windows, a well-locked multi-point locking system should be selected to ensure that the doors are deformed and synchronized under the action of wind pressure, effectively ensure the reasonable cooperation of sealing materials, so that the sealing strip can keep good sealing performance under the strong state of pressure at any time.

You cannot choose cheap and simple single-point lock hardware configuration, because when single-point lock hardware configuration, when doors and windows are under positive wind pressure or negative wind pressure, doors and windows will be deformed without locking points. However, it cannot be homing after deformation, resulting in gaps between fans and frames, making hot and cold air circulate through the gaps between doors and windows, forming convection, which cannot save energy for doors and windows.

IV. Correct assembly

the previous points are the requirements of door and window components, but reasonable selection of components is very important, and the correct combination of various components into a system is a perfect energy-saving door and window, therefore, when we choose door and window assembly plants, it is also crucial to choose powerful and experienced door and window assembly plants.

IV. Correct assembly

the previous points are the requirements of door and window components, but reasonable selection of components is very important, and the correct combination of various components into a system is a perfect energy-saving door and window, therefore, when we choose door and window assembly plants, it is also crucial to choose powerful and experienced door and window assembly plants.

Judging from the three elements of measuring building doors and windows, sliding doors and windows are not in the same plane when they are closed due to structural reasons, while there is no sealing pressure between the two casement and around them, just rely on wool tops to overlap, and there is a gap between wool tops, forming convection phenomenon, so sliding doors and windows are not energy-saving windows.

Judging from the three elements of measuring building doors and windows, sliding doors and windows are not in the same plane when they are closed due to structural reasons, while there is no sealing pressure between the two casement and around them, just rely on wool tops to overlap, and there is a gap between wool tops, forming convection phenomenon, so sliding doors and windows are not energy-saving windows.

Are other open doors and windows energy-saving doors and windows? Other open forms of doors and windows also need comprehensive consideration and reasonable design to meet the requirements of energy saving of doors and windows. But only using energy-saving profiles or energy-saving glass is energy-saving doors and windows? From the above analysis, it is not enough to use only good profiles or glass and accessories for energy-saving doors and windows. The perfect combination of good materials is the element of systematic comprehensive evaluation.

Are other open doors and windows energy-saving doors and windows? Other open forms of doors and windows also need comprehensive consideration and reasonable design to meet the requirements of energy saving of doors and windows. But only using energy-saving profiles or energy-saving glass is energy-saving doors and windows? From the above analysis, it is not enough to use only good profiles or glass and accessories for energy-saving doors and windows. The perfect combination of good materials is the element of systematic comprehensive evaluation.