Foaming agent is mainly used for filling, sealing and bonding the side joints of building doors and windows, expansion joints of components and holes. It is a polyurethane elastic sealed foam material that relies on Moisture curing. It is divided into two types: gun type and tube type. Gun type requires special polyurethane foam gun to be used, and tube type is equipped with disposable hose. It is a single component, Moisture curing, multi-purpose polyurethane foam filling elastic sealing material.

With people's understanding of foaming agent, foaming agent has been widely used in construction, decoration and real estate industries. Due to the huge market of foaming agent, foaming agent manufacturers are springing up like bamboo shoots after a spring rain, which leads to a mixture of good and bad in the foaming agent market, thus "true and false" foaming agent comes out in the market. The so-called "fake" foaming agent is that some illegal manufacturers adopt the method of adding inferior materials to reduce costs to deceive and deceive consumers so as to obtain ultra-high profits.

1. Add powder

In order to reduce the cost, some manufacturers add low-cost powder to the foaming agent, which will not affect the use of the product, but there will be quality problems such as greatly reducing the foaming amount, blocking the valve, shortening the shelf life, etc.

2. Gaza

In order to increase the gram weight of the product, some manufacturers add sand to the product to fake it. If the product is not clean and there is something in the jar after it is finished, it is likely that it is mixed with sand.

3. Come on

This product will ooze grease at the bottom after foaming.

This kind of foaming agent with powder, Gaza, refueling and various additives is aimed at reducing costs to deceive consumers and disrupt the market. So how can our consumption distinguish the quality of foaming agent?

How to distinguish

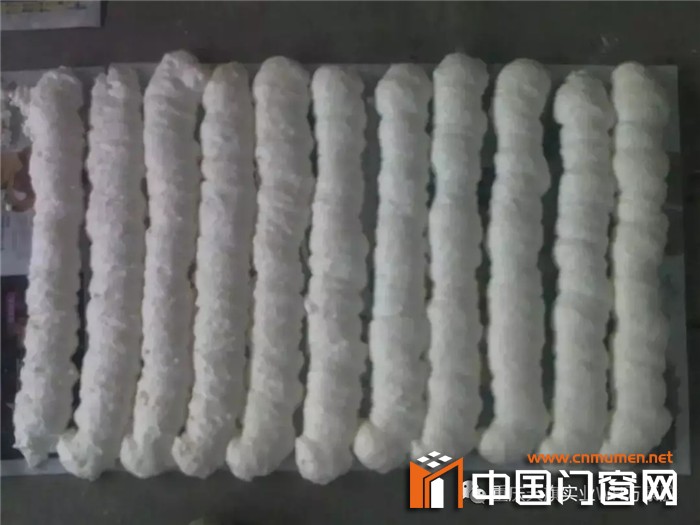

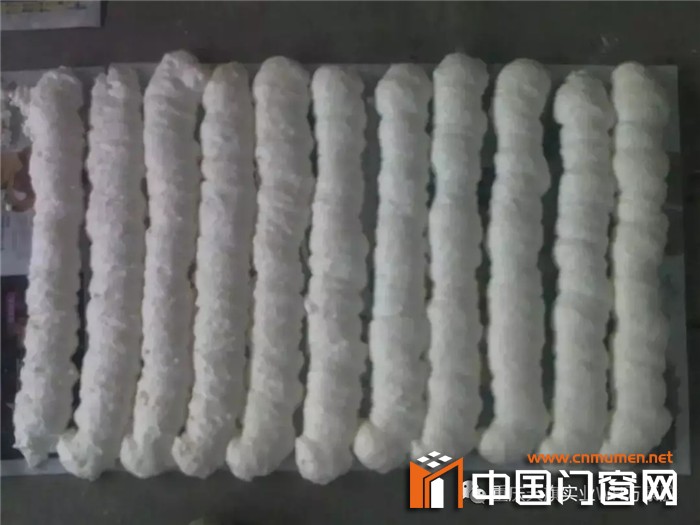

First, look at the size of the foam, the good foam is full and round; The poor foam is small and collapsed.

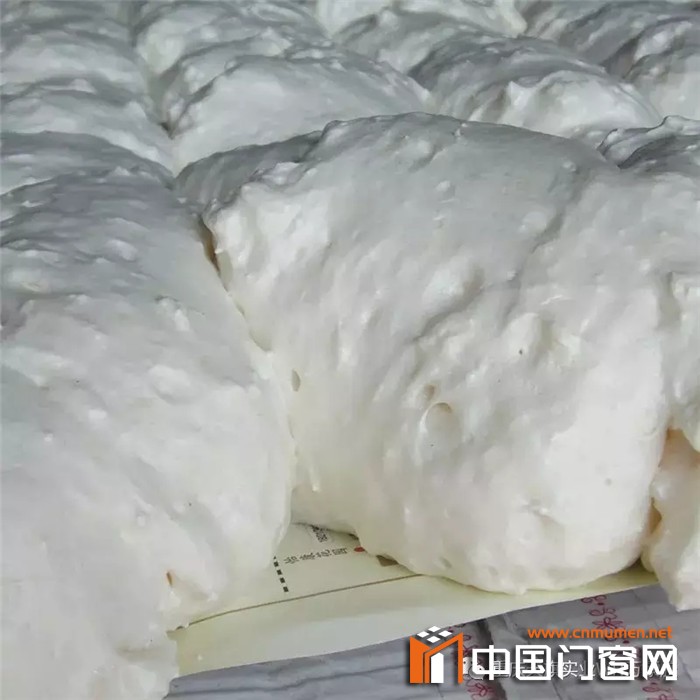

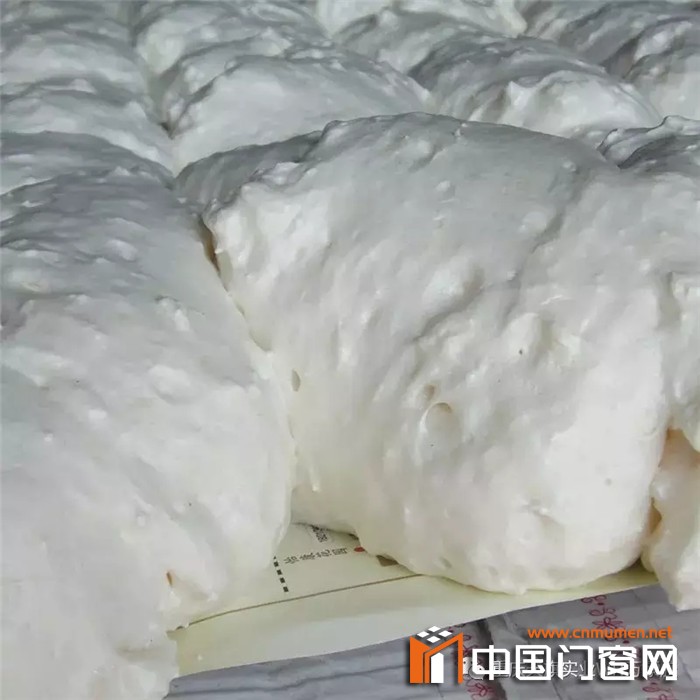

Second, cut the foam, look at the bubble hole, the bubble hole is uniform and fine as good foam, if the bubble hole is very large, and the density is not good.

3. Depending on the adhesion, good foam has strong adhesion, while poor ones have poor adhesion.

4. Gun type, when foam is played, the sprayed foam should not be too thin, not too thick, too thin foam will not collapse, too thick foam will dry, and the foam will shrink easily.

5. Squeeze Styrofoam pieces by hand. Good glue has good dimensional stability. It is elastic after being completely cured, and neither soft nor hard is good.

6. Judging from the color. High-quality foaming agent is Milky White after being injected. The color turns white or yellow is not very good.

VII. After the product is used, shake the tank. Good products will not fail to be cleaned.

Little knowledge

When the construction is under low temperature in winter, due to the low temperature and humidity, the curing speed of colloid becomes slower, and friable phenomenon occurs during the curing process, and even pulverization occurs in severe cases. To solve this problem, we need to start from the following aspects:

① soak material tank in warm water (30 ℃ ~ 50 ℃) before use;

② spray water mist on the substrate surface and colloid surface before and after construction;

③ the formula of Styrofoam is also adjusted with seasonal changes. Choosing winter products will effectively improve the use effect of low temperature;

④ construction is not recommended when the ambient temperature is lower than-5℃, or special measures are taken before construction;

⑤ choose regular manufacturers or distributors channels, which is more trustworthy.

Chinese door and window net-dew for Frost

With people's understanding of foaming agent, foaming agent has been widely used in construction, decoration and real estate industries. Due to the huge market of foaming agent, foaming agent manufacturers are springing up like bamboo shoots after a spring rain, which leads to a mixture of good and bad in the foaming agent market, thus "true and false" foaming agent comes out in the market. The so-called "fake" foaming agent is that some illegal manufacturers adopt the method of adding inferior materials to reduce costs to deceive and deceive consumers so as to obtain ultra-high profits.

1. Add powder

In order to reduce the cost, some manufacturers add low-cost powder to the foaming agent, which will not affect the use of the product, but there will be quality problems such as greatly reducing the foaming amount, blocking the valve, shortening the shelf life, etc.

With people's understanding of foaming agent, foaming agent has been widely used in construction, decoration and real estate industries. Due to the huge market of foaming agent, foaming agent manufacturers are springing up like bamboo shoots after a spring rain, which leads to a mixture of good and bad in the foaming agent market, thus "true and false" foaming agent comes out in the market. The so-called "fake" foaming agent is that some illegal manufacturers adopt the method of adding inferior materials to reduce costs to deceive and deceive consumers so as to obtain ultra-high profits.

1. Add powder

In order to reduce the cost, some manufacturers add low-cost powder to the foaming agent, which will not affect the use of the product, but there will be quality problems such as greatly reducing the foaming amount, blocking the valve, shortening the shelf life, etc.

2. Gaza

In order to increase the gram weight of the product, some manufacturers add sand to the product to fake it. If the product is not clean and there is something in the jar after it is finished, it is likely that it is mixed with sand.

2. Gaza

In order to increase the gram weight of the product, some manufacturers add sand to the product to fake it. If the product is not clean and there is something in the jar after it is finished, it is likely that it is mixed with sand.

3. Come on

This product will ooze grease at the bottom after foaming.

3. Come on

This product will ooze grease at the bottom after foaming.

This kind of foaming agent with powder, Gaza, refueling and various additives is aimed at reducing costs to deceive consumers and disrupt the market. So how can our consumption distinguish the quality of foaming agent?

How to distinguish

First, look at the size of the foam, the good foam is full and round; The poor foam is small and collapsed.

Second, cut the foam, look at the bubble hole, the bubble hole is uniform and fine as good foam, if the bubble hole is very large, and the density is not good.

3. Depending on the adhesion, good foam has strong adhesion, while poor ones have poor adhesion.

4. Gun type, when foam is played, the sprayed foam should not be too thin, not too thick, too thin foam will not collapse, too thick foam will dry, and the foam will shrink easily.

5. Squeeze Styrofoam pieces by hand. Good glue has good dimensional stability. It is elastic after being completely cured, and neither soft nor hard is good.

6. Judging from the color. High-quality foaming agent is Milky White after being injected. The color turns white or yellow is not very good.

VII. After the product is used, shake the tank. Good products will not fail to be cleaned.

This kind of foaming agent with powder, Gaza, refueling and various additives is aimed at reducing costs to deceive consumers and disrupt the market. So how can our consumption distinguish the quality of foaming agent?

How to distinguish

First, look at the size of the foam, the good foam is full and round; The poor foam is small and collapsed.

Second, cut the foam, look at the bubble hole, the bubble hole is uniform and fine as good foam, if the bubble hole is very large, and the density is not good.

3. Depending on the adhesion, good foam has strong adhesion, while poor ones have poor adhesion.

4. Gun type, when foam is played, the sprayed foam should not be too thin, not too thick, too thin foam will not collapse, too thick foam will dry, and the foam will shrink easily.

5. Squeeze Styrofoam pieces by hand. Good glue has good dimensional stability. It is elastic after being completely cured, and neither soft nor hard is good.

6. Judging from the color. High-quality foaming agent is Milky White after being injected. The color turns white or yellow is not very good.

VII. After the product is used, shake the tank. Good products will not fail to be cleaned.

Little knowledge

When the construction is under low temperature in winter, due to the low temperature and humidity, the curing speed of colloid becomes slower, and friable phenomenon occurs during the curing process, and even pulverization occurs in severe cases. To solve this problem, we need to start from the following aspects:

① soak material tank in warm water (30 ℃ ~ 50 ℃) before use;

② spray water mist on the substrate surface and colloid surface before and after construction;

③ the formula of Styrofoam is also adjusted with seasonal changes. Choosing winter products will effectively improve the use effect of low temperature;

④ construction is not recommended when the ambient temperature is lower than-5℃, or special measures are taken before construction;

⑤ choose regular manufacturers or distributors channels, which is more trustworthy.

Chinese door and window net-dew for Frost

Little knowledge

When the construction is under low temperature in winter, due to the low temperature and humidity, the curing speed of colloid becomes slower, and friable phenomenon occurs during the curing process, and even pulverization occurs in severe cases. To solve this problem, we need to start from the following aspects:

① soak material tank in warm water (30 ℃ ~ 50 ℃) before use;

② spray water mist on the substrate surface and colloid surface before and after construction;

③ the formula of Styrofoam is also adjusted with seasonal changes. Choosing winter products will effectively improve the use effect of low temperature;

④ construction is not recommended when the ambient temperature is lower than-5℃, or special measures are taken before construction;

⑤ choose regular manufacturers or distributors channels, which is more trustworthy.

Chinese door and window net-dew for Frost