Many families also install broken bridge aluminum doors and windows as the preferred product, the home decoration market is getting bigger and bigger, attracting many door and window manufacturers to join the home decoration market. Then we will encounter a problem, how to choose good quality broken bridge aluminum doors and windows? How do we analyze its quality? Because of the impact broken bridge aluminum doors and windows there are many factors of quality, so many friends want to know which aspects should they judge its quality? Here we can judge from the following aspects.

In order to protect everyone from suffering, briefly introduce how to identify high-quality profiles and how to choose products that meet national standards from several aspects. First of all, we analyze from three points: first, materials used for profiles, second, processing technology, and third, price.

断桥铝门窗型材用料" alt="断桥铝门窗型材用料" width="850" vspace="0" hspace="0" height="639" border="0" />

断桥铝门窗型材用料" alt="断桥铝门窗型材用料" width="850" vspace="0" hspace="0" height="639" border="0" />

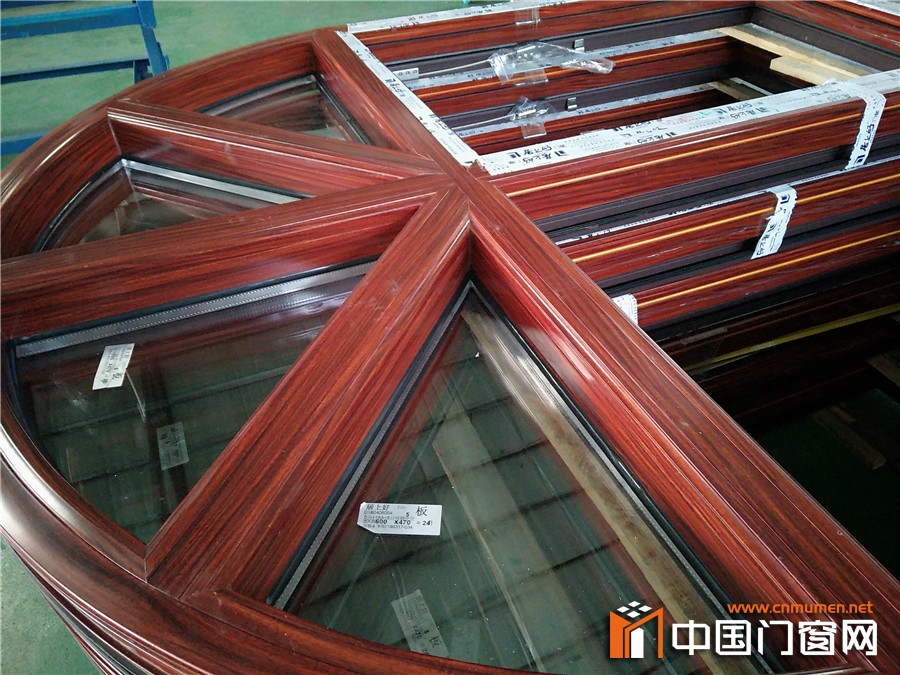

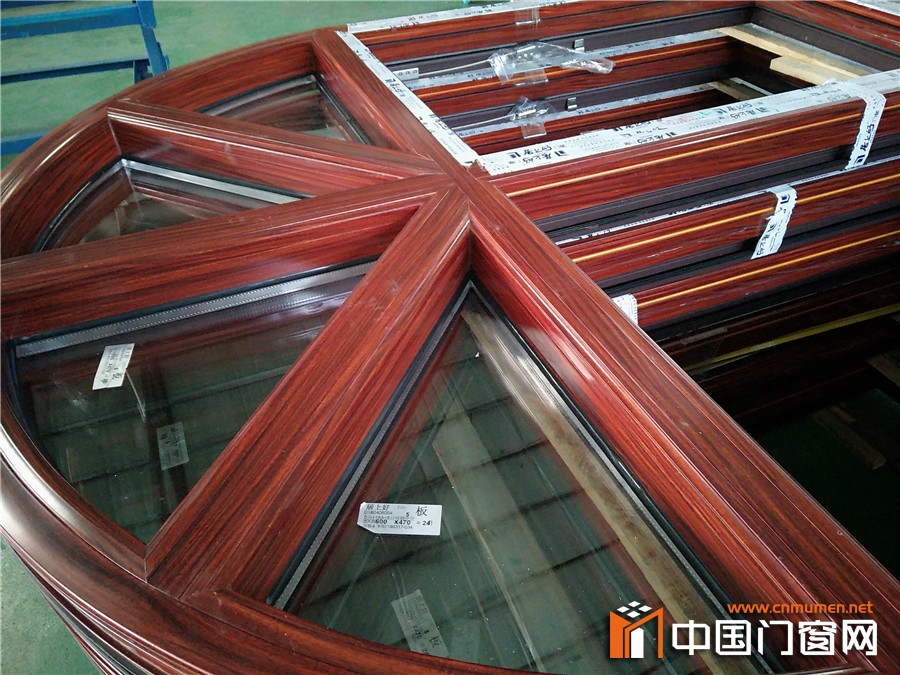

First, look at the materials used for profiles: aluminum profiles used for high-quality aluminum alloy doors and windows, such as thickness, strength and oxide film, shall conform to the relevant national standards and regulations, and the wall thickness shall be above 1.2mm, the tensile strength reaches 157 newtons per square millimeter, the yield strength should reach 108 newtons per square millimeter, and the thickness of oxide film should reach 10 micrometers. If it does not meet the above standards, it is inferior aluminum alloy doors and windows, which cannot be used. According to the National Building Materials standard, aluminum alloy grades of 6063 or 6061 should be used for broken bridge aluminum profiles, which have good rigidity, strength and erosion resistance, at present, the strength, rigidity and erosion resistance of some industrial aluminum alloy or recycled aluminum alloy extruded profiles with bad profiles are much lower than the national standard. If such profiles are used, their product quality is poor.

Profile surface spraying: broken bridge aluminum doors and windows whether the profile is beautiful or not depends mainly on the spraying material and quality. High-grade products generally use fluorine carbon spraying, and home decoration mostly uses powder spraying. Powder spraying is divided into inlet powder and domestic powder, national designated profile production enterprises mostly use inlet powder, which is produced strictly according to the national standard. Many small profile factories simplify the spraying process. Without cadmium treatment equipment, the spraying quality cannot be guaranteed.

断桥铝门窗质量辨别" alt="断桥铝门窗质量辨别" style="white-space: normal; width: 850px; height: 639px;" width="850" vspace="0" hspace="0" height="639" border="0" />

断桥铝门窗质量辨别" alt="断桥铝门窗质量辨别" style="white-space: normal; width: 850px; height: 639px;" width="850" vspace="0" hspace="0" height="639" border="0" />

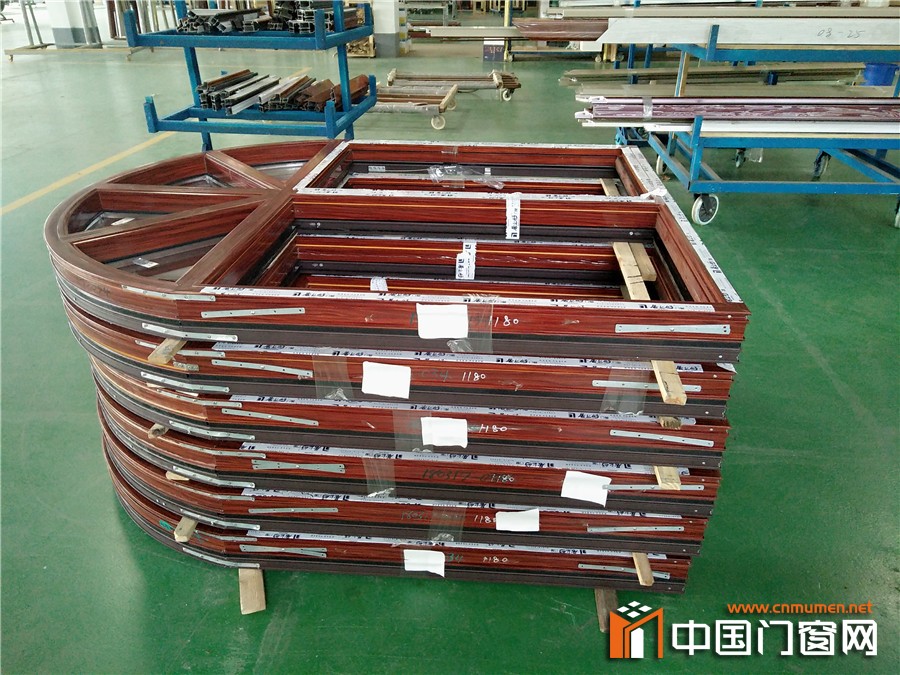

Broken Bridge aluminum insulation strip: currently, broken bridge aluminum doors and windows it has become a commonly used equipment for medium and high-grade buildings in Foshan. Only the low-end market of plastic-steel windows is close to exiting the historical stage, and it is only widely used in affordable housing. Secondly, the cutting surface of the profile can be observed. The section of the national standard product is smooth and bright, the density is high, the heat insulation strip is dark, the alloy section density of the inferior product is low, the gloss is dark, and the heat insulation strip is rough. According to the national standard, PA66 nylon material must be used for the insulation strip of broken bridge aluminum profile. Because only PA66 nylon has very close strength, temperature deformation coefficient and mechanical function to aluminum alloy, and it has good aging resistance, only when PA66 nylon heat insulation strip is used can the strength between the heat insulation strip and aluminum alloy ensure the overall durability of the product in case of temperature change and mechanical deformation.

How to identify inferior profiles: the price of inferior aluminum alloy door and window profile is 10-20% lower than that of national standard products. Once used, the loss to customers will be incalculable. How can we identify it??

Manufacturers can be required to provide product invoices, profile factory production license and product factory certificate, and go to the door and window factory to check whether the profile packaging is consistent with the document. The coating thickness of the national standard products is relatively large and uniform. The metal surface is cadmium-treated before spraying, and the process is slightly yellow, with a strength of adhesion of coatings. At present, many manufacturers in the home decoration market choose PVC plastic insulation Strip Products. Because the strength of PVC is far lower than that of aluminum alloy and the deformation coefficient is far different from that of aluminum alloy, the anti-aging ability is general, therefore, the use of such profiles will seriously affect the safety and service life of doors and windows.

Profile wall thickness: the national standard stipulates that the wall thickness of broken bridge aluminum main profile should not be less than 1.4mm. At present, there are many products in the home decoration market whose thickness is lower than this standard. Generally, small factories will not tell you.

断桥铝门窗生产加工" alt="断桥铝门窗生产加工" style="white-space: normal; width: 850px; height: 639px;" width="850" vspace="0" hspace="0" height="639" border="0" />

断桥铝门窗生产加工" alt="断桥铝门窗生产加工" style="white-space: normal; width: 850px; height: 639px;" width="850" vspace="0" hspace="0" height="639" border="0" />

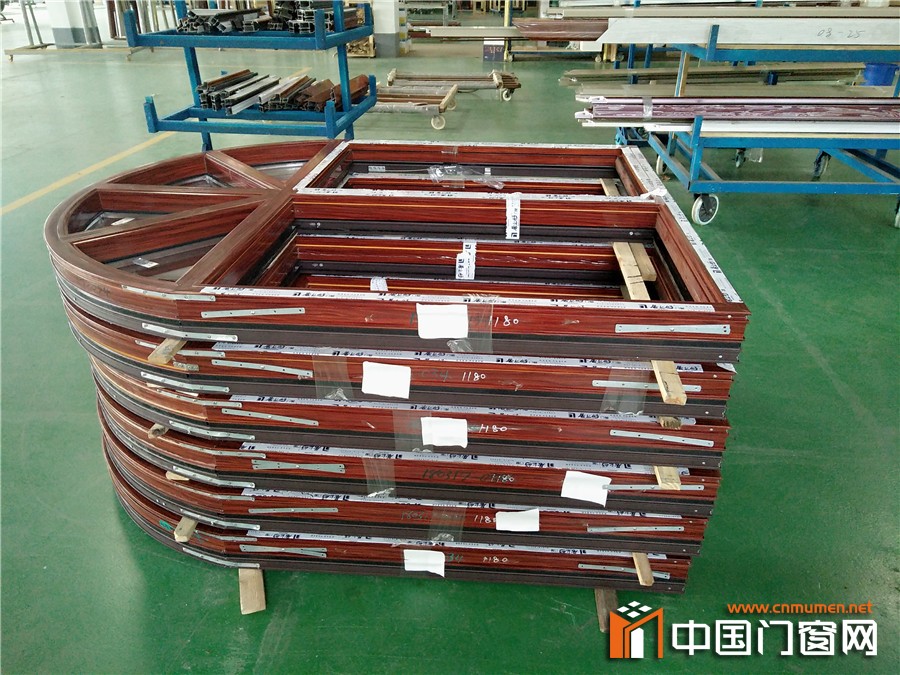

Second, look at the processing. High quality aluminum alloy doors and windows, finely processed, exquisite installation, good sealing performance, easy to switch. The inferior aluminum alloy doors and windows blindly select aluminum profile series and specifications, and process rough and crude products. Saw cutting is used instead of milling. They are not installed as required. The sealing performance is poor and the switch is not easy, not only leakage of wind, leakage of rain and cracking of glass, but also encounter strong wind and external force, which makes it easy to scrape or knock off the push and pull part or glass, damaging things and hurting people. In order to reduce costs, some manufacturers use products that do not conform to national standards during home decoration, causing serious potential safety hazards to customers.

3. Look at the price. Under normal circumstances, the price of high-quality aluminum alloy doors and windows is about 30% higher than that of inferior aluminum alloy doors and windows due to the high production cost. Some aluminum alloy doors and windows with a wall thickness of only 0.6-0.8mm are made of aluminum profiles, and the tensile strength and yield strength are much lower than the relevant national standards, so it is not safe to use. In addition, at present, there are many self-employed workers processing aluminum alloy doors and windows, and they do not know the structural characteristics and performance of aluminum alloy doors and windows. In order to reduce costs, cut corners and shoddy, the hidden danger of the product is relatively large, which is generally not suitable for use. About identification good quality aluminum alloy doors and windows there are many parameters, and it is best to choose the doors and windows of regular aluminum alloy doors and windows manufacturers.

断桥铝门窗型材用料" alt="

断桥铝门窗型材用料" alt=" 断桥铝门窗质量辨别" alt="

断桥铝门窗质量辨别" alt=" 断桥铝门窗生产加工" alt="

断桥铝门窗生产加工" alt="