As people pay more and more attention to balcony space, the functional requirements of balcony windows are getting higher and higher,

broken bridge aluminum doors and windows adopting heat insulation broken bridge aluminum profile and hollow glass, it has the functions of energy saving, sound insulation, noise protection, dustproof, waterproof and so on. About

broken bridge aluminum doors and windows, how much do you know?

Broken Bridge aluminum advantages:

1. Reduce Heat Conduction: adopt insulation broken bridge aluminum alloy profile, and its heat-conduction coefficient is 1.8~3.5W/? · k is much lower than ordinary aluminum alloy profiles 140~170W/? · k; Using hollow glass structure, its heat-conduction coefficient is 2.0~3.59W/m2 · k is much lower than that of ordinary aluminum alloy profiles 6.69~6.84W/? · k, effectively reduces the heat conduction through doors and windows.

2. Prevent condensation: the temperature of the inner surface of the profile with heat insulation strip is close to the indoor temperature, reducing the possibility that indoor moisture condenses on the surface of the profile due to saturation.

3. Energy saving: in winter, the window frame with heat insulation strip can reduce 1/3 of the lost heat through the window frame; In summer, if there is air conditioning, window frames with heat insulation strips can reduce energy loss more.

4. Environmental Protection: through the application of heat insulation system, energy consumption can be reduced, and environmental radiation caused by air conditioning and heating can be reduced at the same time. Good for health: the heat exchange between human body and environment depends on indoor air temperature, air flow speed and outdoor air temperature. By adjusting the indoor temperature of doors and windows to make it not less than 12 ~ 13℃, it has reached the most comfortable environment.

5. Noise reduction: the hollow glass structure with different thickness and the cavity structure of heat insulation broken bridge aluminum profile can effectively reduce the resonance effect of sound waves, prevent the transmission of sound, and reduce the noise by more than 30dB.

6. Colorful colors: aluminum profiles of different colors can be produced after surface treatment with anodic oxidation, powder spraying and fluorocarbon spraying. After rolling combination, insulated aluminum alloy doors and windows can be produced indoors, two-tone windows of different colors outside.

Broken Bridge aluminum performance:

1,

broken bridge aluminum doors and windows good thermal insulation. It adopts the soft combination of inner and outer frames of heat insulation profiles, and the frame adopts a plastic strip and three sealing forms of double wool strips. It is tightly closed, with excellent air tightness, water tightness and excellent heat preservation performance; Casement adopts hollow glass structure, the window really shows sound insulation, heat insulation, heat preservation and excellent function, greatly saving the cost of mining and refrigeration. The heat transfer coefficient K value is less than 2.23-2.94w/2K after testing, and the energy saving effect is remarkable, several years of energy-saving costs are enough to make up for the previous investment.

2,

broken bridge aluminum doors and windows waterproof function. The structural drainage system is designed by using the principle of pressure balance, and the inclined surface step type is designed for sliding down, and the drainage port is set, so that the drainage is smooth and the water tightness is good.

3,

broken bridge aluminum doors and windows anti-condensation and frost. The Broken Bridge aluminum profile can realize the three sealing structure of doors and windows, reasonably separate the water vapor chamber, successfully realize the equal pressure balance of air and water, significantly improve the water tightness and air tightness of doors and windows, and achieve the effect of clean and bright windows.

4,

broken bridge aluminum doors and windows anti Mosquito car window shade design. Invisible car window shade, support inner and outer choose to install and use, with anti mosquito, flies, especially suitable for mosquito areas in the north.

5,

broken bridge aluminum doors and windows anti-theft and anti-loosening device. Equipped with standard hardware locks to ensure the stability and safety of windows in use.

6,

broken bridge aluminum doors and windows noise protection sound insulation. The structure is carefully designed, the joints are tight, and the test results show that the air sound insulation reaches 30-40db, which can ensure that residents within 50 meters on both sides of the expressway are not disturbed by noise, adjacent to the downtown can also ensure the quiet and warm interior.

7,

broken bridge aluminum doors and windows fire resistance. Aluminum Alloy is made of metal material, and the insulation strip is made of PA66 + GF25 (commonly known as nylon insulation strip) without burning and has good high temperature resistance.

8,

broken bridge aluminum doors and windows, against wind and sand, wind pressure resistance. Inner frame straight material adopts hollow design, strong wind pressure deformation resistance and good off register resistance. It can be used in high-rise buildings and residential buildings, and can design large-area window type with large lighting area. This kind of window has good air tightness and can ensure that there is no dust on the indoor windowsill and floor in areas with large wind and sand.

9,

broken bridge aluminum doors and windows high strength unchanged type, maintenance-free. Broken Bridge aluminum The form has high tensile strength, shear strength and thermal deformation resistance, and is strong and durable. Broken Bridge aluminum the profile is not easily eroded by acid and alkali, is not easy to turn yellow and fade, and almost does not need maintenance.

10,

broken bridge aluminum doors and windows A variety of colors, very decorative. It can achieve different colors of indoor and outdoor surfaces of doors and windows, meet customers' preference for color effect, and meet the aesthetic requirements of color gamut space, and meet the personalized design requirements of architects. The aluminum profile adopts streamlined design and is luxurious and stylish.

11,

broken bridge aluminum doors and windows green building materials, circular economy.

Broken bridge aluminum doors and windows in the production process, not only harmful materials will not be generated, but all materials can be recycled and recycled. It is a green building material environmental protection product, which conforms to the sustainable development of human beings.

12,

broken bridge aluminum doors and windows there are many opening forms, which are comfortable and durable. It has flat type, incline type, upper suspension type, push-pull type, flat type, incline type and compound type, etc.

Broken bridge aluminum doors and windows

Broken bridge aluminum doors and windows scope of Application:

Applicable to public buildings, residential quarters and municipal projects; High-quality hardware accessories are durable, and the operating handle is designed with humanized design, which is beautiful and comfortable, convenient and flexible to open, and every use action has been tested, fatigue test times are over tens of thousands of times, sliding easily and silently, mature and perfect door and window processing technology, high precision program control processing center for production, stable and guaranteed quality.

The outstanding advantages of insulation broken bridge aluminum alloy doors and windows are: high strength, good thermal insulation, good rigidity, good fire resistance, large lighting area, good atmospheric corrosion resistance, high comprehensive performance, long service life and good decorative effect, using high-grade aluminum alloy doors and windows with broken bridge partition profiles is the first choice for high-grade building windows.

Broken bridge aluminum doors and windows classification:

1. According to the opening method, it can be divided into: fixed windows, upper hanging window, middle hanging window, lower hanging window, vertical window, flat open door and window, pulley casement window, pulley window, flat open lower hanging door and window, sliding door window, push and pull casement window, folding door, floor spring door, lifting sliding door, sliding folding door, pour inside side sliding door.

2. According to the performance, it can be divided into: ordinary doors and windows, sound insulation doors and windows, insulation doors and windows.

3. According to the application parts, it can be divided into internal doors and windows and external doors and windows.

Among them, the mainstream market is divided into the following three categories:

Upper suspension type

Hanging window this is a kind of aluminum alloy and plastic steel window that appeared later. It is a new form developed on the basis of casement window. It has two opening modes, which can be opened flat and pushed away from the upper part. When Casement window is closed, pull the upper part of the window inward to open a gap of about ten centimeters, that is, the window can be opened a little from above, and the open part is suspended in the air, it is connected and fixed with window frame through hinges and so on, so it is called upper suspension type. Its advantages are: it can not only ventilate, but also ensure safety. Because there are hinges, the window can only open the seam of ten centimeters, and it cannot be reached from the outside, which is especially suitable for use when no one is at home. This function is not only limited to flat windows, but also can be opened on the sliding window.

Vertical hinged door

Vertical hinged door has single open vertical hinged door and double open vertical hinged door: single door means only one door panel, while double door has two door panels. Vertical hinged door is divided into one-way opening and two-way opening. One-way opening can only open in one direction (only push in or pull out) two-way opening is that the door leaf can open in two directions (for example, falling door). Vertical hinged door is divided relative to other opening methods, because the door also has mobile opening, upturning, rolling shutter lifting, vertical lifting, rotary, etc.

Sliding door

Sliding Door originated from China and spread to North Korea and Japan through Chinese culture. In terms of meaning: push the pull door; In terms of materials: There are wood, metal, organic and inorganic materials; In terms of use: Used in bookcases, closet, bedrooms, living rooms, the door of the exhibition hall is used. Sliding Door originated in China and spread to Korea and Japan through Chinese culture. There is no way to verify the specific time, but we can see scattered sliding door from some ancient paintings in China. For example, there are sliding door landscape paintings in Song Dynasty. The original sliding door was only used for sliding door of the bedroom or wardrobe in the stool room, but with the development of technology and the diversification of decoration methods, from traditional plate surface to glass, fabric, rattan, aluminum alloy profiles, from sliding door, folding door to partition door, the functions and usage range of sliding door are constantly expanding. In this case, the application of sliding door began to become diverse and abundant. In addition to the most common partition door, sliding door is widely used in bookcases, closet, living rooms, showrooms, sliding doors, etc.

Broken bridge aluminum doors and windows

Broken bridge aluminum doors and windows distinction between advantages and disadvantages:

I. Look at the surface quality of profiles

The quality of the profile can be observed from the surface of the Broken Bridge aluminum profile. The surface of the good Broken Bridge aluminum profile is glossy and textured, and the surface spraying color treatment will also be natural, and it feels smooth when looking at it; Secondary

broken bridge aluminum doors and windows the surface is rough, not shiny, looks unnatural, after using it for a period of time, it is poor

broken bridge aluminum doors and windows there will be discoloration or fading, and the color will not be full.

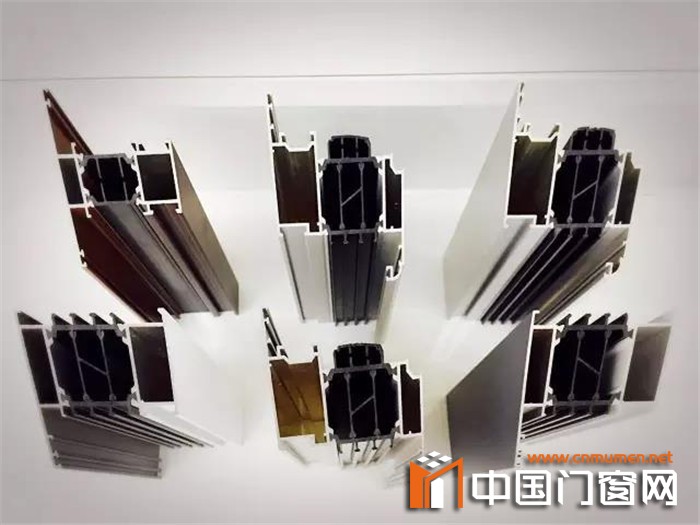

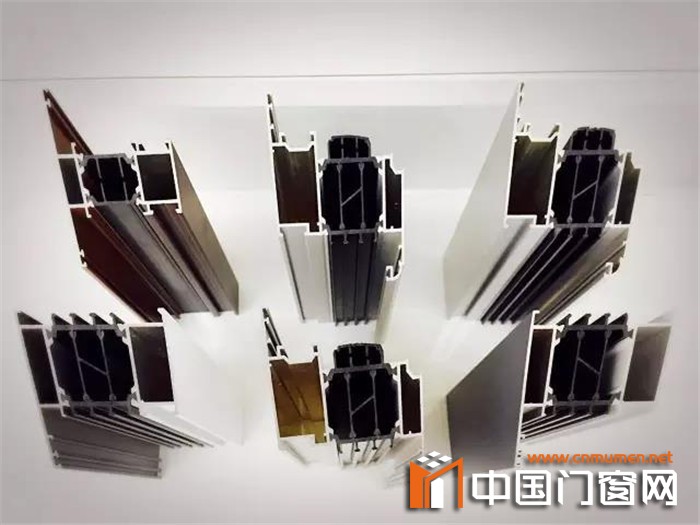

Second, look at the profile section structure

OK

broken bridge aluminum doors and windows the geometric angle of the profile section is accurate, the profile will not be bent and twisted, and the angle is correct. And the thickness of the cut surface is sufficient, for example, the 60 model you customized

broken bridge aluminum doors and windows, 60 refers to the thickness of the profile is 6 centimeters, and these 6 centimeters are divided into full broken bridge aluminum materials, and the proportion of threading is small;

broken bridge aluminum doors and windows, 60 profiles with virtual support will be used, and the thickness will be supported by wearing strips. The material of aluminum is relatively small.

3. Look at the heat insulation strip of the profile

Insulation strips are imported and domestic. Most domestic insulation strips are made of plastic PVC, while imported insulation strips are made of polyamide, that is, nylon insulation strips. Good quality

broken bridge aluminum doors and windows, the imported heat insulation strip adopted has better high temperature resistance and low temperature resistance, and low heat conduction value, which can better realize the effect of heat insulation, environmental protection and energy saving, and can save 20%-30% of energy.

Inferior quality

broken bridge aluminum doors and windows the five most commonly used "moves"

The first is "stealing beams and changing columns":

The relevant state departments with low cost clearly stipulate that it can only be used for general plastics of non-structural materials --- polyvinyl chloride (PVC) insulation strip (hereinafter referred to as PVC insulation strip) to replace the glass fiber reinforced polyamide nylon (PA66) insulation strip (hereinafter referred to as nylon 66 insulation strip) which has been widely used in europe for decades. Because the linear expansion coeffcient (8.3*10-5K-1) of PVC is far from the linear expansion coeffcient (2.35*10-5K-1) of aluminum alloy, and its strength is low (only about 30N/mm2) and its heat resistance is poor (80℃), many defects, such as poor aging quality resistance, lead to the thermal insulation doors and windows made of insulated aluminum profiles made of PVC thermal insulation strips through strips. After actual installation and use, due to thermal expansion and contraction, PVC thermal insulation strips will loosen in aluminum profiles, even completely separated, light will lead to loose and deformed windows, thus damaging the air tightness and water tightness of doors and windows, while heavy will lead to loose and separated windows as a whole.

The second is to hide from the world and cross the sea ":

In the case of thermal insulation aluminum doors and windows project, there are many enterprises bidding with thermal insulation sample windows of imported Nylon 66 thermal insulation strips, after winning the bid, PVC insulation strips or domestic nylon insulation strips are used for actual processing or imported nylon 66 insulation strips are mixed with PVC or other insulation strips, while imported nylon 66 insulation strips with trademark marks are facing outside, to "prove" the "quality grade identity" of the heat insulation strip used ". This kind of "hiding from the World" has strong concealment. The owners of heat-insulated aluminum doors and windows can only identify the heat-insulated aluminum profiles before they are processed, because only the two heat insulation strips at this time can be identified.

The third is "fishing in troubled waters":

The material of heat insulation strip is the basic guarantee of the quality of heat insulation doors and windows, but it is by no means the only guarantee. In 2003, domestic nylon insulation strips began to be put on the market. In order to reduce costs, domestic nylon insulation strips used general mineral materials (commonly known as fillers) to fill polyamide nylon for processing and production instead of glass fibers. This kind of heat insulation strip cannot be compared with nylon 66 heat insulation strip reinforced by glass fiber in terms of mechanical strength, heat resistance and aging quality resistance. Moreover, since the industry standard of "heat insulation strip" for national construction is still in the final approval process, domestic nylon heat insulation strip carries out relevant performance testing with injection molding parts made by mixing nylon with common minerals, and the obtained test report is used as the performance test report of the finished heat insulation strip. The test data of this raw material can only represent its material performance, and the performance of finished products produced after hot extrusion, cooling and other processing technologies will greatly change.

The fourth is "opportunistic":

Some insulated aluminum doors and windows enterprises have fully studied and grasped PVC insulation strips, after the big performance difference between domestic nylon insulation strip and imported Nylon 66 insulation strip, a compromise scheme of both economy and relative insurance is adopted: the window frame aluminum profile adopts low quality and low price PVC or domestic nylon insulation strip, casement aluminum profile adopts high quality imported Nylon 66 heat insulation strip. They believe that the window frame aluminum profile is fixed on the wall, even if there is a quality risk, there will be no big problem, while the Casement aluminum profile is movable and bears stress alone, therefore, we cannot and dare not have quality risks.

The fifth is "filling up the number of excessive flowers":

Some insulated aluminum doors and windows enterprises are studying people's psychology. People only care about the material quality of heat insulation strips, but seldom consider the alloy quality of the outer two layers of aluminum alloy. According to the national standard, the aluminum alloy of building profiles is 6063-brand alloy, however, some enterprises use substandard aluminum alloy for insulated aluminum composite doors and windows, resulting in casement. The corners of window frames are not tight, and it is difficult for doors and windows to be insulated and insulated. Therefore, not only the insulation strip has good or bad quality, but also its aluminum alloy depends on its hardness and strength. There are also differences between Electrostatic spraying and electrophoretic painting on the surface of the profile. The former is a physical change, for more information, see Baidu Encyclopedia "Electrostatic spraying technology", the latter is chemical change, please see Baidu Encyclopedia "electrophoresis technology". "Electrophoresis process" was founded in the 1960 s and was first applied to automobile primer by Ford Motor Company. Due to its excellent non-fading and anti-corrosion functions, it was soon widely used in the military industry. It has only been applied to the surface treatment of doors and windows in recent years. Due to its excellent quality and high environmental protection, it is gradually replacing traditional paint spraying. Electrophoresis is that under the action of voltage, the charged paint ions move to the cathode and form insoluble matter with the alkaline action on the cathode surface, the paint is deposited on the surface of the aluminum alloy.

To sum up, we can see that before the industry standard of special insulation strip for insulated aluminum alloy doors and windows has not yet been issued, there has been a worrying phenomenon in the insulated aluminum doors and windows market, however, the main reason for these phenomena is that the owners of the insulated doors and windows project do not have a comprehensive and profound understanding of the new technology of insulated aluminum doors and windows. However, we should appeal to people of insight in the door and window industry to standardize this disorderly competition as soon as possible with an objective and scientific attitude, a state that regards product quality as its lifeblood, and a professional ethics that is responsible to consumers. The professional attitude of being responsible for the quality of products and the quality of people's lives is the principle of establishing enterprises and people. Otherwise, even if relevant standards are issued, it is useless. Setting standards is to check the quality of products, without quality awareness, everything becomes useless.

How do consumers buy

broken bridge aluminum doors and windows what about it?

See materials:

Aluminum profiles used for high-quality aluminum alloy doors and windows, such as thickness, strength and oxide film, shall conform to the relevant national standards and regulations. The wall thickness of the inelastic window assembly structure shall be more than 1.4mm, the wall thickness of door inelastic assembly structure is over 2.0mm. The tensile strength reaches 157 newtons per square millimeter, the yield strength should reach 108 newtons per square millimeter, and the thickness of oxide film should reach 10 micrometers. If it does not meet the above standards, it is inferior aluminum alloy doors and windows, which cannot be used.

See processing:

High quality aluminum alloy doors and windows, finely processed, exquisite installation, good sealing performance, easy to switch. Inferior aluminum alloy doors and windows blindly choose aluminum profile series and specifications, rough processing, saw cutting instead of milling processing, do not install as required, poor sealing performance, not easy to switch, not only leakage of wind, leakage of rain and cracking of glass, but also encounter strong wind and external force, which makes it easy to scrape or knock off the push and pull part or glass, damaging things and hurting people.

Look at the price:

Under normal circumstances, high-quality aluminum alloy doors and windows are about 30% higher than inferior aluminum alloy doors and windows due to their high production cost. Some aluminum alloy doors and windows with a wall thickness of only 0.6-0.8mm are made of aluminum profiles, and the tensile strength and yield strength are much lower than the relevant national standards and regulations, so it is not safe to use.

Editor: China door and window network -- ak

2. Prevent condensation: the temperature of the inner surface of the profile with heat insulation strip is close to the indoor temperature, reducing the possibility that indoor moisture condenses on the surface of the profile due to saturation.

3. Energy saving: in winter, the window frame with heat insulation strip can reduce 1/3 of the lost heat through the window frame; In summer, if there is air conditioning, window frames with heat insulation strips can reduce energy loss more.

4. Environmental Protection: through the application of heat insulation system, energy consumption can be reduced, and environmental radiation caused by air conditioning and heating can be reduced at the same time. Good for health: the heat exchange between human body and environment depends on indoor air temperature, air flow speed and outdoor air temperature. By adjusting the indoor temperature of doors and windows to make it not less than 12 ~ 13℃, it has reached the most comfortable environment.

5. Noise reduction: the hollow glass structure with different thickness and the cavity structure of heat insulation broken bridge aluminum profile can effectively reduce the resonance effect of sound waves, prevent the transmission of sound, and reduce the noise by more than 30dB.

6. Colorful colors: aluminum profiles of different colors can be produced after surface treatment with anodic oxidation, powder spraying and fluorocarbon spraying. After rolling combination, insulated aluminum alloy doors and windows can be produced indoors, two-tone windows of different colors outside.

2. Prevent condensation: the temperature of the inner surface of the profile with heat insulation strip is close to the indoor temperature, reducing the possibility that indoor moisture condenses on the surface of the profile due to saturation.

3. Energy saving: in winter, the window frame with heat insulation strip can reduce 1/3 of the lost heat through the window frame; In summer, if there is air conditioning, window frames with heat insulation strips can reduce energy loss more.

4. Environmental Protection: through the application of heat insulation system, energy consumption can be reduced, and environmental radiation caused by air conditioning and heating can be reduced at the same time. Good for health: the heat exchange between human body and environment depends on indoor air temperature, air flow speed and outdoor air temperature. By adjusting the indoor temperature of doors and windows to make it not less than 12 ~ 13℃, it has reached the most comfortable environment.

5. Noise reduction: the hollow glass structure with different thickness and the cavity structure of heat insulation broken bridge aluminum profile can effectively reduce the resonance effect of sound waves, prevent the transmission of sound, and reduce the noise by more than 30dB.

6. Colorful colors: aluminum profiles of different colors can be produced after surface treatment with anodic oxidation, powder spraying and fluorocarbon spraying. After rolling combination, insulated aluminum alloy doors and windows can be produced indoors, two-tone windows of different colors outside.

Broken Bridge aluminum performance:

1,

Broken Bridge aluminum performance:

1,

Among them, the mainstream market is divided into the following three categories:

Upper suspension type

Hanging window this is a kind of aluminum alloy and plastic steel window that appeared later. It is a new form developed on the basis of casement window. It has two opening modes, which can be opened flat and pushed away from the upper part. When Casement window is closed, pull the upper part of the window inward to open a gap of about ten centimeters, that is, the window can be opened a little from above, and the open part is suspended in the air, it is connected and fixed with window frame through hinges and so on, so it is called upper suspension type. Its advantages are: it can not only ventilate, but also ensure safety. Because there are hinges, the window can only open the seam of ten centimeters, and it cannot be reached from the outside, which is especially suitable for use when no one is at home. This function is not only limited to flat windows, but also can be opened on the sliding window.

Vertical hinged door

Vertical hinged door has single open vertical hinged door and double open vertical hinged door: single door means only one door panel, while double door has two door panels. Vertical hinged door is divided into one-way opening and two-way opening. One-way opening can only open in one direction (only push in or pull out) two-way opening is that the door leaf can open in two directions (for example, falling door). Vertical hinged door is divided relative to other opening methods, because the door also has mobile opening, upturning, rolling shutter lifting, vertical lifting, rotary, etc.

Sliding door

Sliding Door originated from China and spread to North Korea and Japan through Chinese culture. In terms of meaning: push the pull door; In terms of materials: There are wood, metal, organic and inorganic materials; In terms of use: Used in bookcases, closet, bedrooms, living rooms, the door of the exhibition hall is used. Sliding Door originated in China and spread to Korea and Japan through Chinese culture. There is no way to verify the specific time, but we can see scattered sliding door from some ancient paintings in China. For example, there are sliding door landscape paintings in Song Dynasty. The original sliding door was only used for sliding door of the bedroom or wardrobe in the stool room, but with the development of technology and the diversification of decoration methods, from traditional plate surface to glass, fabric, rattan, aluminum alloy profiles, from sliding door, folding door to partition door, the functions and usage range of sliding door are constantly expanding. In this case, the application of sliding door began to become diverse and abundant. In addition to the most common partition door, sliding door is widely used in bookcases, closet, living rooms, showrooms, sliding doors, etc.

Among them, the mainstream market is divided into the following three categories:

Upper suspension type

Hanging window this is a kind of aluminum alloy and plastic steel window that appeared later. It is a new form developed on the basis of casement window. It has two opening modes, which can be opened flat and pushed away from the upper part. When Casement window is closed, pull the upper part of the window inward to open a gap of about ten centimeters, that is, the window can be opened a little from above, and the open part is suspended in the air, it is connected and fixed with window frame through hinges and so on, so it is called upper suspension type. Its advantages are: it can not only ventilate, but also ensure safety. Because there are hinges, the window can only open the seam of ten centimeters, and it cannot be reached from the outside, which is especially suitable for use when no one is at home. This function is not only limited to flat windows, but also can be opened on the sliding window.

Vertical hinged door

Vertical hinged door has single open vertical hinged door and double open vertical hinged door: single door means only one door panel, while double door has two door panels. Vertical hinged door is divided into one-way opening and two-way opening. One-way opening can only open in one direction (only push in or pull out) two-way opening is that the door leaf can open in two directions (for example, falling door). Vertical hinged door is divided relative to other opening methods, because the door also has mobile opening, upturning, rolling shutter lifting, vertical lifting, rotary, etc.

Sliding door

Sliding Door originated from China and spread to North Korea and Japan through Chinese culture. In terms of meaning: push the pull door; In terms of materials: There are wood, metal, organic and inorganic materials; In terms of use: Used in bookcases, closet, bedrooms, living rooms, the door of the exhibition hall is used. Sliding Door originated in China and spread to Korea and Japan through Chinese culture. There is no way to verify the specific time, but we can see scattered sliding door from some ancient paintings in China. For example, there are sliding door landscape paintings in Song Dynasty. The original sliding door was only used for sliding door of the bedroom or wardrobe in the stool room, but with the development of technology and the diversification of decoration methods, from traditional plate surface to glass, fabric, rattan, aluminum alloy profiles, from sliding door, folding door to partition door, the functions and usage range of sliding door are constantly expanding. In this case, the application of sliding door began to become diverse and abundant. In addition to the most common partition door, sliding door is widely used in bookcases, closet, living rooms, showrooms, sliding doors, etc.