Broken Bridge insulated aluminum alloy doors and windows have outstanding advantages such as high strength, good thermal insulation, good rigidity, good fire resistance, large lighting area, good corrosion resistance, high comprehensive performance, long service life, good decorative effect, etc, more and more favored by the market. High-grade broken bridge insulated aluminum alloy doors and windows have gradually become the preferred product for high-grade building windows.

Why is it called "Broken Bridge insulation aluminum"?

"Bridge" in the name of "Broken Bridge insulation aluminum" refers to "cold and hot Bridge" in the sense of material science, while the word "broken" indicates action, that is, "breaking cold and hot Bridge".

Specifically, because aluminum alloy is a metal, the heat conduction is relatively fast, so when the indoor and outdoor temperatures differ a lot, aluminum alloy can become a "bridge" that transfers heat. Such materials are made into doors and windows, its thermal insulation performance is not good. However, broken bridge aluminum disconnects the aluminum alloy from the middle. It uses heat insulation strips to connect the disconnected aluminum alloy into one. In this way, heat cannot easily pass through the whole material, and the heat insulation performance of the material becomes better, this is the origin of the name "Broken Bridge insulation aluminum.

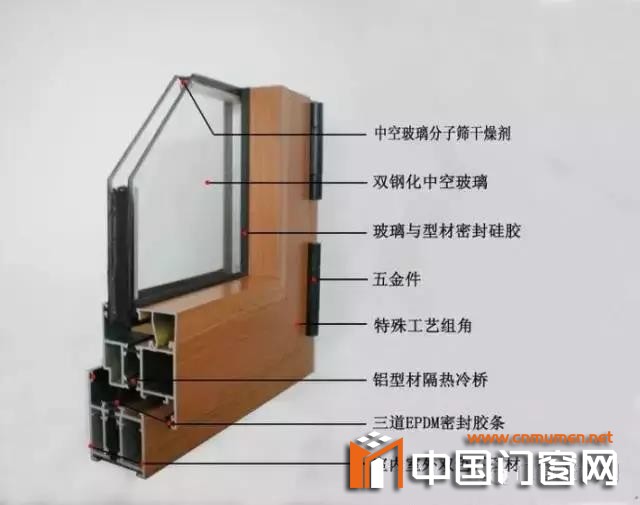

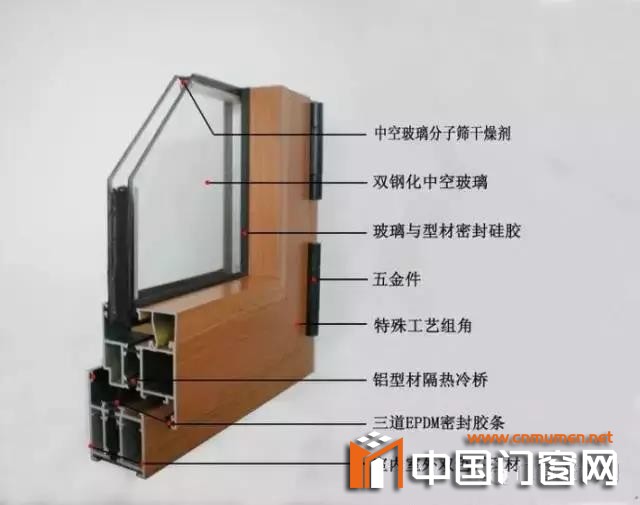

Broken bridge aluminum doors and windows generally speaking, it contains two main bodies: Broken Bridge insulated aluminum profile and hollow glass.

Analysis of advantages of broken bridge insulation aluminum

1. Broken Bridge insulation aluminum thermal insulation is good. The inner and outer frame of the heat insulation profile is combined with the softness, and the frame is sealed by EPDM strip, which is tightly closed, with excellent air tightness, water tightness and excellent heat preservation performance. Casement the hollow glass structure is adopted to make the window truly show sound insulation, heat insulation, heat preservation, excellent function, a large amount of savings in mining and refrigeration costs, heat transfer coefficient K value after testing 1.8-2.5w/2K, energy saving effect is remarkable, several years of energy-saving costs are enough to make up for the previous investment.

2. Broken Bridge insulation aluminum waterproof function. The structural drainage system is designed by using the principle of pressure balance, and the drainage port is set, so that the drainage is smooth and the water tightness is good.

3. Broken Bridge insulation aluminum prevents condensation and frost. The Broken Bridge aluminum profile can realize the three-way sealing structure of doors and windows, many of which can even reach 8 seals, reasonably separate the water vapor chamber, successfully realize the equal pressure balance between air and water, and significantly improve the water tightness and air tightness of doors and windows, achieve the effect of clear and bright windows.

4. Design of broken bridge insulation aluminum anti mosquito car window shade. Invisible car window shade, support inner and outer choose to install and use, with anti mosquito, flies, especially suitable for mosquito areas in the north. You can also select security screen window, which has anti-theft function.

5. Broken Bridge insulation aluminum anti-theft and anti-loosening device. Equipped with unique multi-point hardware locks to ensure the stability and safety of windows in use.

6. Broken Bridge insulation aluminum noise protection sound insulation. The structure is carefully designed, the joints are tight, and the test results show that the air sound insulation reaches 30-40db, which can ensure that residents within 50 meters on both sides of the expressway are not disturbed by noise, adjacent to the downtown can also ensure the quiet and warm interior.

7. Broken Bridge insulation aluminum fire resistance. Aluminum Alloy is metal material and will not burn.

8. Broken Bridge insulation aluminum against wind and sand, wind pressure resistance. Inner frame straight material adopts hollow design, strong wind pressure deformation resistance and good off register resistance. Can be used in high-rise buildings and residential buildings, can design large-area window type, large lighting area; The air tightness of this window is better than any aluminum or plastic window, it can ensure that there is no dust on the indoor windowsill and floor in areas with strong wind and sand.

9. Broken Bridge insulation aluminum high strength unchanged type, maintenance-free.

Broken bridge aluminum doors and windows the tensile strength, shear strength and thermal deformation resistance of the body are high, strong and durable. Broken Bridge aluminum profile is not easy to be eroded by acid and alkali, not easy to turn yellow and fade, almost no maintenance.

10. Broken Bridge insulation aluminum has many colors and is very decorative. It can achieve different colors of indoor and outdoor surfaces of doors and windows, meet customers' preference for color effect, and meet the aesthetic requirements of color gamut space, and meet the personalized design requirements of architects. The aluminum profile adopts streamlined design and is luxurious and stylish.

11. Broken Bridge insulation aluminum aluminum green building materials, circular economy.

Broken bridge aluminum doors and windows in the production process, not only harmful materials will not be generated, but all materials can be recycled and recycled. It is a green building material environmental protection product, which conforms to the sustainable development of human beings.

12. There are many open forms of broken bridge insulation aluminum, which are comfortable and durable. It has flat open type, incline type, upper suspension type, push-pull type, flat open type, incline type and composite type, etc., and is suitable for public buildings, residential quarters and municipal engineering; High-quality hardware accessories are durable, and the user-friendly design of the operating handle, beautiful and comfortable, easy to open and flexible, every use action has been tested, the number of fatigue tests has reached more than tens of thousands of times, sliding easily and silently, mature and perfect door and window processing technology, high precision program control machining center for production, stable and guaranteed quality.

Material characteristics of broken bridge insulation aluminum

01. Bridge-cutoff aluminum alloy doors and windows is a relatively high-grade aluminum alloy doors and windows. It is the fifth generation of new thermal insulation and energy-saving doors and windows after wooden windows, iron window, plastic steel doors and windows and ordinary colored aluminum alloy doors and windows. Its surface can be painted into various colors.

02. The composition structure of the broken bridge color aluminum alloy doors and windows is combined with wooden window environmental protection, iron window and copper window solid security, plastic steel doors and windows heat preservation and energy saving. Its structure is more complex than ordinary aluminum doors and windows, and its cost is higher. Ordinary colored aluminum does not have heat insulation strips, and heat preservation not available does not save energy. It is only sprayed on the surface.

03. The wall thickness of profile section of bridge-cutoff aluminum alloy doors and windows strictly follows the national standard. The wall thickness requirements must be between 1.4 and 2.0mm, because the wall thickness is related to the assembly technology and the firm safety of the doors and windows. The wall thickness of ordinary color aluminum doors and windows should generally be below 1.4mm.

04. The color aluminum doors and windows of the Broken Bridge use a special angle code of more than 3mm to set the angle, and the angle glue should be injected into the corner to seal. However, ordinary doors and windows are only connected by pull rivet or screws, and their firmness and safety are poor, but the cost is low. And assembled color

broken bridge aluminum doors and windows there will be no problem for adults to stand up and walk. The technical requirements of assembling complete sets of equipment are far different from those assembled by manual on-site operation. Special broken bridge aluminum profile and ordinary aluminum profile are not of the same grade and cannot be compared.

How to judge the advantages and disadvantages of broken bridge aluminum profiles?

Profile wall thickness:

generally, for home decoration products, most door and window factories choose products with high output rate, that is, products with relatively thin wall thickness to reduce the cost, and 1.3 thick is lower than the national standard. The national standard stipulates that the thickness of the profile should be greater than or equal to 1.4mm.

Heat insulation strip:

PA66 nylon must be used for the most critical part of the Broken Bridge aluminum profile, which is stipulated by the national standard. However, many manufacturers in the decoration market use cheap PVC plastic insulation strips at present, this will seriously affect the service life and safety of the product.

Why is it called "Broken Bridge insulation aluminum"?

"Bridge" in the name of "Broken Bridge insulation aluminum" refers to "cold and hot Bridge" in the sense of material science, while the word "broken" indicates action, that is, "breaking cold and hot Bridge".

Specifically, because aluminum alloy is a metal, the heat conduction is relatively fast, so when the indoor and outdoor temperatures differ a lot, aluminum alloy can become a "bridge" that transfers heat. Such materials are made into doors and windows, its thermal insulation performance is not good. However, broken bridge aluminum disconnects the aluminum alloy from the middle. It uses heat insulation strips to connect the disconnected aluminum alloy into one. In this way, heat cannot easily pass through the whole material, and the heat insulation performance of the material becomes better, this is the origin of the name "Broken Bridge insulation aluminum.

Why is it called "Broken Bridge insulation aluminum"?

"Bridge" in the name of "Broken Bridge insulation aluminum" refers to "cold and hot Bridge" in the sense of material science, while the word "broken" indicates action, that is, "breaking cold and hot Bridge".

Specifically, because aluminum alloy is a metal, the heat conduction is relatively fast, so when the indoor and outdoor temperatures differ a lot, aluminum alloy can become a "bridge" that transfers heat. Such materials are made into doors and windows, its thermal insulation performance is not good. However, broken bridge aluminum disconnects the aluminum alloy from the middle. It uses heat insulation strips to connect the disconnected aluminum alloy into one. In this way, heat cannot easily pass through the whole material, and the heat insulation performance of the material becomes better, this is the origin of the name "Broken Bridge insulation aluminum.

Analysis of advantages of broken bridge insulation aluminum

1. Broken Bridge insulation aluminum thermal insulation is good. The inner and outer frame of the heat insulation profile is combined with the softness, and the frame is sealed by EPDM strip, which is tightly closed, with excellent air tightness, water tightness and excellent heat preservation performance. Casement the hollow glass structure is adopted to make the window truly show sound insulation, heat insulation, heat preservation, excellent function, a large amount of savings in mining and refrigeration costs, heat transfer coefficient K value after testing 1.8-2.5w/2K, energy saving effect is remarkable, several years of energy-saving costs are enough to make up for the previous investment.

2. Broken Bridge insulation aluminum waterproof function. The structural drainage system is designed by using the principle of pressure balance, and the drainage port is set, so that the drainage is smooth and the water tightness is good.

3. Broken Bridge insulation aluminum prevents condensation and frost. The Broken Bridge aluminum profile can realize the three-way sealing structure of doors and windows, many of which can even reach 8 seals, reasonably separate the water vapor chamber, successfully realize the equal pressure balance between air and water, and significantly improve the water tightness and air tightness of doors and windows, achieve the effect of clear and bright windows.

4. Design of broken bridge insulation aluminum anti mosquito car window shade. Invisible car window shade, support inner and outer choose to install and use, with anti mosquito, flies, especially suitable for mosquito areas in the north. You can also select security screen window, which has anti-theft function.

5. Broken Bridge insulation aluminum anti-theft and anti-loosening device. Equipped with unique multi-point hardware locks to ensure the stability and safety of windows in use.

6. Broken Bridge insulation aluminum noise protection sound insulation. The structure is carefully designed, the joints are tight, and the test results show that the air sound insulation reaches 30-40db, which can ensure that residents within 50 meters on both sides of the expressway are not disturbed by noise, adjacent to the downtown can also ensure the quiet and warm interior.

7. Broken Bridge insulation aluminum fire resistance. Aluminum Alloy is metal material and will not burn.

8. Broken Bridge insulation aluminum against wind and sand, wind pressure resistance. Inner frame straight material adopts hollow design, strong wind pressure deformation resistance and good off register resistance. Can be used in high-rise buildings and residential buildings, can design large-area window type, large lighting area; The air tightness of this window is better than any aluminum or plastic window, it can ensure that there is no dust on the indoor windowsill and floor in areas with strong wind and sand.

9. Broken Bridge insulation aluminum high strength unchanged type, maintenance-free.

Analysis of advantages of broken bridge insulation aluminum

1. Broken Bridge insulation aluminum thermal insulation is good. The inner and outer frame of the heat insulation profile is combined with the softness, and the frame is sealed by EPDM strip, which is tightly closed, with excellent air tightness, water tightness and excellent heat preservation performance. Casement the hollow glass structure is adopted to make the window truly show sound insulation, heat insulation, heat preservation, excellent function, a large amount of savings in mining and refrigeration costs, heat transfer coefficient K value after testing 1.8-2.5w/2K, energy saving effect is remarkable, several years of energy-saving costs are enough to make up for the previous investment.

2. Broken Bridge insulation aluminum waterproof function. The structural drainage system is designed by using the principle of pressure balance, and the drainage port is set, so that the drainage is smooth and the water tightness is good.

3. Broken Bridge insulation aluminum prevents condensation and frost. The Broken Bridge aluminum profile can realize the three-way sealing structure of doors and windows, many of which can even reach 8 seals, reasonably separate the water vapor chamber, successfully realize the equal pressure balance between air and water, and significantly improve the water tightness and air tightness of doors and windows, achieve the effect of clear and bright windows.

4. Design of broken bridge insulation aluminum anti mosquito car window shade. Invisible car window shade, support inner and outer choose to install and use, with anti mosquito, flies, especially suitable for mosquito areas in the north. You can also select security screen window, which has anti-theft function.

5. Broken Bridge insulation aluminum anti-theft and anti-loosening device. Equipped with unique multi-point hardware locks to ensure the stability and safety of windows in use.

6. Broken Bridge insulation aluminum noise protection sound insulation. The structure is carefully designed, the joints are tight, and the test results show that the air sound insulation reaches 30-40db, which can ensure that residents within 50 meters on both sides of the expressway are not disturbed by noise, adjacent to the downtown can also ensure the quiet and warm interior.

7. Broken Bridge insulation aluminum fire resistance. Aluminum Alloy is metal material and will not burn.

8. Broken Bridge insulation aluminum against wind and sand, wind pressure resistance. Inner frame straight material adopts hollow design, strong wind pressure deformation resistance and good off register resistance. Can be used in high-rise buildings and residential buildings, can design large-area window type, large lighting area; The air tightness of this window is better than any aluminum or plastic window, it can ensure that there is no dust on the indoor windowsill and floor in areas with strong wind and sand.

9. Broken Bridge insulation aluminum high strength unchanged type, maintenance-free.  Material characteristics of broken bridge insulation aluminum

01. Bridge-cutoff aluminum alloy doors and windows is a relatively high-grade aluminum alloy doors and windows. It is the fifth generation of new thermal insulation and energy-saving doors and windows after wooden windows, iron window, plastic steel doors and windows and ordinary colored aluminum alloy doors and windows. Its surface can be painted into various colors.

02. The composition structure of the broken bridge color aluminum alloy doors and windows is combined with wooden window environmental protection, iron window and copper window solid security, plastic steel doors and windows heat preservation and energy saving. Its structure is more complex than ordinary aluminum doors and windows, and its cost is higher. Ordinary colored aluminum does not have heat insulation strips, and heat preservation not available does not save energy. It is only sprayed on the surface.

03. The wall thickness of profile section of bridge-cutoff aluminum alloy doors and windows strictly follows the national standard. The wall thickness requirements must be between 1.4 and 2.0mm, because the wall thickness is related to the assembly technology and the firm safety of the doors and windows. The wall thickness of ordinary color aluminum doors and windows should generally be below 1.4mm.

04. The color aluminum doors and windows of the Broken Bridge use a special angle code of more than 3mm to set the angle, and the angle glue should be injected into the corner to seal. However, ordinary doors and windows are only connected by pull rivet or screws, and their firmness and safety are poor, but the cost is low. And assembled color

Material characteristics of broken bridge insulation aluminum

01. Bridge-cutoff aluminum alloy doors and windows is a relatively high-grade aluminum alloy doors and windows. It is the fifth generation of new thermal insulation and energy-saving doors and windows after wooden windows, iron window, plastic steel doors and windows and ordinary colored aluminum alloy doors and windows. Its surface can be painted into various colors.

02. The composition structure of the broken bridge color aluminum alloy doors and windows is combined with wooden window environmental protection, iron window and copper window solid security, plastic steel doors and windows heat preservation and energy saving. Its structure is more complex than ordinary aluminum doors and windows, and its cost is higher. Ordinary colored aluminum does not have heat insulation strips, and heat preservation not available does not save energy. It is only sprayed on the surface.

03. The wall thickness of profile section of bridge-cutoff aluminum alloy doors and windows strictly follows the national standard. The wall thickness requirements must be between 1.4 and 2.0mm, because the wall thickness is related to the assembly technology and the firm safety of the doors and windows. The wall thickness of ordinary color aluminum doors and windows should generally be below 1.4mm.

04. The color aluminum doors and windows of the Broken Bridge use a special angle code of more than 3mm to set the angle, and the angle glue should be injected into the corner to seal. However, ordinary doors and windows are only connected by pull rivet or screws, and their firmness and safety are poor, but the cost is low. And assembled color