The installation of doors and windows is a relatively fine work in the process of home decoration. A little deviation will affect the overall use effect. Moreover, for ordinary families, the service life of doors and windows is relatively long, when decorating, you need to take extra care to ensure its service life.

However, although we pay great attention to it, there will always be some minor problems, and some even we haven't noticed. Today, I will talk to you about some mistakes and preventive measures that often occur during the installation of doors and windows.

Common construction problems--

1. There is a large deviation in the front verticality of the outer frame of doors and windows, especially the tenons of wooden doors and windows are not dense, and the joints are easy to be warped and deformed, which affects the aesthetics and practicability in the later period.

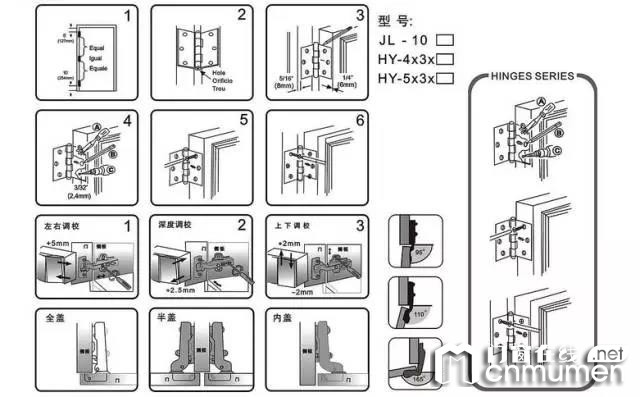

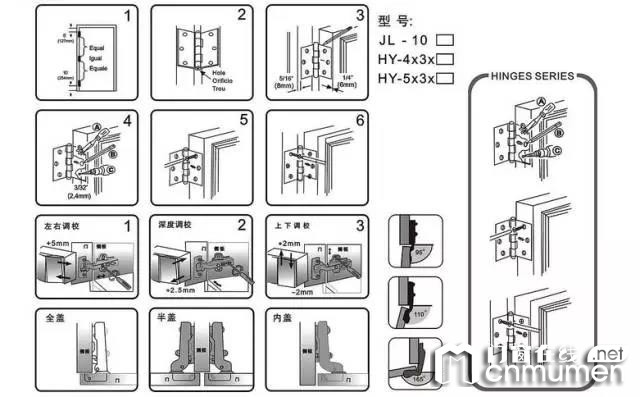

2. There is a deviation in the installation of the hardware hinge position of the door and window, the size of the hinge slot is inconsistent, the edge of the door and window is not smooth, and the screw installation is not accurate enough.

3. The gap between the vertical seam and the joint of doors and windows is too large, which leads to the intight closing of doors and windows. It is easy to leak wind in winter, and rain easily flows into the room in rainy days.

Preventive measures--

1. The installation project of doors and windows should be carried out in strict accordance with the construction specifications. Qualified materials should be purchased and operated according to the correct construction requirements. The owner also needs to check and accept the materials in time.

2. The hardware hinge position of the doors and windows must be accurate. The hinge corresponds to the size of the hinge slot, and the depth is the same. The installation position of the hinge should be at the height of 1/10 of the upper and lower sections of the doors and windows.

3. The opening and closing of doors and windows should be flexible and smooth. Make sure that the edge of the doors and windows has no problems of lifting and rebound. The installation of screws must be accurate, and avoid twisting and twisting, the joints of doors and windows must be properly connected.

4. The lower frame device of the window frame should be lifted. After the window sill is plastered with cement, the slope top and the lower frame of the window should be kept at a height greater than 8mm and made into a concave arc angle, in this way, the window drainage will be smoother.

5. The door and window package window frame process can prevent the damage of the door and window and prolong the service life of the door and window.

Before installation, check the shape and position accuracy of the door and window openings, check whether the quantity and position of embedded concrete meet the design requirements, and whether high-rise windows are connected to lightning protection belts according to regulations, for unqualified parts, the construction unit should be urged to rectify.

1. Scribing positioning

(1) According to the installation position, size and elevation of doors and windows in the design drawings, measure the edge lines of doors and windows to both sides according to the center line of doors and windows. If it is a multi-storey or high-rise building, The Edge line of the top door and window shall prevail, and the edge of the door and window shall be led off with a line pendant or a theodolite, and marked at the door and window of each floor, and some non-straight edges shall be cut and chisel.

(2) the horizontal position of the doors and windows should be based on the horizontal line of 1250px in the floor. The height of the doors and windows should be measured up and down leather tag, and the elastic line should be straight. Each layer must keep the height of leather tag under the window consistent.

2. Aluminium windows water-covering installation

According to the requirements of the construction drawings, fix the water on the aluminium windows, and ensure that the position is correct and the installation is firm.

3. Anti-corrosion treatment

(1) when the design of anti-corrosion treatment on the outer surface around the door and window frame is required, it shall be handled according to the design requirements. If there is no requirement in the design, anticorrosive paint can be painted or plastic film can be pasted for protection, so as to prevent cement mortar from directly contacting the surface of aluminum alloy doors and windows, producing electrochemical reaction and corroding aluminum alloy doors and windows.

(2) when installing aluminum alloy doors and windows, if connecting iron parts are used for fixing, it is better to use SST part for connecting iron parts, fixing parts and other installation metal parts. Otherwise, anti-corrosion treatment must be carried out to avoid electrochemical reaction and corrosion of aluminum alloy doors and windows.

4. Installation of aluminum alloy doors and windows in place

Install aluminum alloy door and window frame according to the marked positioning line of doors and windows. And adjust the horizontal, vertical and diagonal length of the door and window frame in time to meet the quality standards, and then temporarily fix it with wooden wedge.

5. Fixing of aluminum alloy doors and windows

(1) When iron parts are embedded on the wall, the iron feet of aluminum alloy doors and windows can be directly welded with the embedded iron parts on the wall, and the welding place needs rust prevention treatment.

(2) when there are no embedded iron parts on the wall, metal expansion bolts or plastic expansion bolts can be used to fix the iron feet of aluminum alloy doors and windows to the wall.

(3) when there are no embedded iron parts on the wall, electric drill can also be used to punch 80mm deep and 6mm diameter holes on the wall, and L-type 80mm × 50mm 6rmn steel bar is used. Stick 108 glue mud on the long end and drive it into the hole. After 108 glue mud is finally solidified, the iron feet of aluminum alloy doors and windows and the embedded 6mm steel bar shall be welded firmly.

6. Treatment of gap between door and window frame and wall

(1) after the installation and fixing of aluminum alloy doors and windows, the concealed engineering acceptance should be carried out first, and the gap between the door and window frame and the wall should be handled timely according to the design requirements after passing the acceptance.

(2) If the design is not required, elastic insulation materials or glass wool felt strips can be used to layer fill plug gaps, and 5~8mm deep notches on the outer surface can be filled with embedded joint ointment or sealant.

7. Installation of door and window fan and door and window glass

1) doors and windows fan and doors and windows glass should be installed after the completion of the opening wall surface finishing.

2) after the sliding doors and windows are installed and fixed in the door and window frame, install the doors and windows with glass into the slide in the frame as a whole, and adjust the gap between the frame and the fan.

3) flat open doors and windows assemble the frame and the fan on the wall grillwork, install and fix it, then install the glass, that is, adjust the gap between the frame and the fan first, then make the glass fan and adjust the position, finally, insert sealing strip and sealant.

4) the floor spring door should be fixed after the door frame and floor spring main engine are installed. First embed the glass into the door leaf grillwork and put the frame together, adjust the gap of the frame leaf, and finally fill in the sealing strip and sealant of the door leaf glass.

8. Construction precautions

1) pay attention to the assembly quality when adopting multiple sets of combined doors and windows. The Assembly head should be flat without cutting edges and corners.

2) during the construction, the product protection must be strictly done, the damaged and dropped protection laminating film and film should be sealed in time, and the mortar dirt splashed on the surface of doors and windows should be removed in time to avoid the pollution and bite of the surface layer of doors and windows.

3) the thickness of the door and window glass should conform to the national standards and design requirements with the size of the fan-inlay groove and sealing strip. When installing the sealing strip, there should be room for expansion to avoid the sealing strip falling off.

News source: door and window maniac

However, although we pay great attention to it, there will always be some minor problems, and some even we haven't noticed. Today, I will talk to you about some mistakes and preventive measures that often occur during the installation of doors and windows.

Common construction problems--

However, although we pay great attention to it, there will always be some minor problems, and some even we haven't noticed. Today, I will talk to you about some mistakes and preventive measures that often occur during the installation of doors and windows.

Common construction problems--

1. There is a large deviation in the front verticality of the outer frame of doors and windows, especially the tenons of wooden doors and windows are not dense, and the joints are easy to be warped and deformed, which affects the aesthetics and practicability in the later period.

2. There is a deviation in the installation of the hardware hinge position of the door and window, the size of the hinge slot is inconsistent, the edge of the door and window is not smooth, and the screw installation is not accurate enough.

3. The gap between the vertical seam and the joint of doors and windows is too large, which leads to the intight closing of doors and windows. It is easy to leak wind in winter, and rain easily flows into the room in rainy days.

Preventive measures--

1. There is a large deviation in the front verticality of the outer frame of doors and windows, especially the tenons of wooden doors and windows are not dense, and the joints are easy to be warped and deformed, which affects the aesthetics and practicability in the later period.

2. There is a deviation in the installation of the hardware hinge position of the door and window, the size of the hinge slot is inconsistent, the edge of the door and window is not smooth, and the screw installation is not accurate enough.

3. The gap between the vertical seam and the joint of doors and windows is too large, which leads to the intight closing of doors and windows. It is easy to leak wind in winter, and rain easily flows into the room in rainy days.

Preventive measures--

1. The installation project of doors and windows should be carried out in strict accordance with the construction specifications. Qualified materials should be purchased and operated according to the correct construction requirements. The owner also needs to check and accept the materials in time.

2. The hardware hinge position of the doors and windows must be accurate. The hinge corresponds to the size of the hinge slot, and the depth is the same. The installation position of the hinge should be at the height of 1/10 of the upper and lower sections of the doors and windows.

3. The opening and closing of doors and windows should be flexible and smooth. Make sure that the edge of the doors and windows has no problems of lifting and rebound. The installation of screws must be accurate, and avoid twisting and twisting, the joints of doors and windows must be properly connected.

4. The lower frame device of the window frame should be lifted. After the window sill is plastered with cement, the slope top and the lower frame of the window should be kept at a height greater than 8mm and made into a concave arc angle, in this way, the window drainage will be smoother.

5. The door and window package window frame process can prevent the damage of the door and window and prolong the service life of the door and window.

1. The installation project of doors and windows should be carried out in strict accordance with the construction specifications. Qualified materials should be purchased and operated according to the correct construction requirements. The owner also needs to check and accept the materials in time.

2. The hardware hinge position of the doors and windows must be accurate. The hinge corresponds to the size of the hinge slot, and the depth is the same. The installation position of the hinge should be at the height of 1/10 of the upper and lower sections of the doors and windows.

3. The opening and closing of doors and windows should be flexible and smooth. Make sure that the edge of the doors and windows has no problems of lifting and rebound. The installation of screws must be accurate, and avoid twisting and twisting, the joints of doors and windows must be properly connected.

4. The lower frame device of the window frame should be lifted. After the window sill is plastered with cement, the slope top and the lower frame of the window should be kept at a height greater than 8mm and made into a concave arc angle, in this way, the window drainage will be smoother.

5. The door and window package window frame process can prevent the damage of the door and window and prolong the service life of the door and window.

Before installation, check the shape and position accuracy of the door and window openings, check whether the quantity and position of embedded concrete meet the design requirements, and whether high-rise windows are connected to lightning protection belts according to regulations, for unqualified parts, the construction unit should be urged to rectify.

1. Scribing positioning

(1) According to the installation position, size and elevation of doors and windows in the design drawings, measure the edge lines of doors and windows to both sides according to the center line of doors and windows. If it is a multi-storey or high-rise building, The Edge line of the top door and window shall prevail, and the edge of the door and window shall be led off with a line pendant or a theodolite, and marked at the door and window of each floor, and some non-straight edges shall be cut and chisel.

(2) the horizontal position of the doors and windows should be based on the horizontal line of 1250px in the floor. The height of the doors and windows should be measured up and down leather tag, and the elastic line should be straight. Each layer must keep the height of leather tag under the window consistent.

2. Aluminium windows water-covering installation

According to the requirements of the construction drawings, fix the water on the aluminium windows, and ensure that the position is correct and the installation is firm.

3. Anti-corrosion treatment

(1) when the design of anti-corrosion treatment on the outer surface around the door and window frame is required, it shall be handled according to the design requirements. If there is no requirement in the design, anticorrosive paint can be painted or plastic film can be pasted for protection, so as to prevent cement mortar from directly contacting the surface of aluminum alloy doors and windows, producing electrochemical reaction and corroding aluminum alloy doors and windows.

(2) when installing aluminum alloy doors and windows, if connecting iron parts are used for fixing, it is better to use SST part for connecting iron parts, fixing parts and other installation metal parts. Otherwise, anti-corrosion treatment must be carried out to avoid electrochemical reaction and corrosion of aluminum alloy doors and windows.

4. Installation of aluminum alloy doors and windows in place

Install aluminum alloy door and window frame according to the marked positioning line of doors and windows. And adjust the horizontal, vertical and diagonal length of the door and window frame in time to meet the quality standards, and then temporarily fix it with wooden wedge.

5. Fixing of aluminum alloy doors and windows

(1) When iron parts are embedded on the wall, the iron feet of aluminum alloy doors and windows can be directly welded with the embedded iron parts on the wall, and the welding place needs rust prevention treatment.

(2) when there are no embedded iron parts on the wall, metal expansion bolts or plastic expansion bolts can be used to fix the iron feet of aluminum alloy doors and windows to the wall.

(3) when there are no embedded iron parts on the wall, electric drill can also be used to punch 80mm deep and 6mm diameter holes on the wall, and L-type 80mm × 50mm 6rmn steel bar is used. Stick 108 glue mud on the long end and drive it into the hole. After 108 glue mud is finally solidified, the iron feet of aluminum alloy doors and windows and the embedded 6mm steel bar shall be welded firmly.

6. Treatment of gap between door and window frame and wall

(1) after the installation and fixing of aluminum alloy doors and windows, the concealed engineering acceptance should be carried out first, and the gap between the door and window frame and the wall should be handled timely according to the design requirements after passing the acceptance.

(2) If the design is not required, elastic insulation materials or glass wool felt strips can be used to layer fill plug gaps, and 5~8mm deep notches on the outer surface can be filled with embedded joint ointment or sealant.

7. Installation of door and window fan and door and window glass

1) doors and windows fan and doors and windows glass should be installed after the completion of the opening wall surface finishing.

2) after the sliding doors and windows are installed and fixed in the door and window frame, install the doors and windows with glass into the slide in the frame as a whole, and adjust the gap between the frame and the fan.

3) flat open doors and windows assemble the frame and the fan on the wall grillwork, install and fix it, then install the glass, that is, adjust the gap between the frame and the fan first, then make the glass fan and adjust the position, finally, insert sealing strip and sealant.

4) the floor spring door should be fixed after the door frame and floor spring main engine are installed. First embed the glass into the door leaf grillwork and put the frame together, adjust the gap of the frame leaf, and finally fill in the sealing strip and sealant of the door leaf glass.

8. Construction precautions

1) pay attention to the assembly quality when adopting multiple sets of combined doors and windows. The Assembly head should be flat without cutting edges and corners.

2) during the construction, the product protection must be strictly done, the damaged and dropped protection laminating film and film should be sealed in time, and the mortar dirt splashed on the surface of doors and windows should be removed in time to avoid the pollution and bite of the surface layer of doors and windows.

3) the thickness of the door and window glass should conform to the national standards and design requirements with the size of the fan-inlay groove and sealing strip. When installing the sealing strip, there should be room for expansion to avoid the sealing strip falling off.

News source: door and window maniac

Before installation, check the shape and position accuracy of the door and window openings, check whether the quantity and position of embedded concrete meet the design requirements, and whether high-rise windows are connected to lightning protection belts according to regulations, for unqualified parts, the construction unit should be urged to rectify.

1. Scribing positioning

(1) According to the installation position, size and elevation of doors and windows in the design drawings, measure the edge lines of doors and windows to both sides according to the center line of doors and windows. If it is a multi-storey or high-rise building, The Edge line of the top door and window shall prevail, and the edge of the door and window shall be led off with a line pendant or a theodolite, and marked at the door and window of each floor, and some non-straight edges shall be cut and chisel.

(2) the horizontal position of the doors and windows should be based on the horizontal line of 1250px in the floor. The height of the doors and windows should be measured up and down leather tag, and the elastic line should be straight. Each layer must keep the height of leather tag under the window consistent.

2. Aluminium windows water-covering installation

According to the requirements of the construction drawings, fix the water on the aluminium windows, and ensure that the position is correct and the installation is firm.

3. Anti-corrosion treatment

(1) when the design of anti-corrosion treatment on the outer surface around the door and window frame is required, it shall be handled according to the design requirements. If there is no requirement in the design, anticorrosive paint can be painted or plastic film can be pasted for protection, so as to prevent cement mortar from directly contacting the surface of aluminum alloy doors and windows, producing electrochemical reaction and corroding aluminum alloy doors and windows.

(2) when installing aluminum alloy doors and windows, if connecting iron parts are used for fixing, it is better to use SST part for connecting iron parts, fixing parts and other installation metal parts. Otherwise, anti-corrosion treatment must be carried out to avoid electrochemical reaction and corrosion of aluminum alloy doors and windows.

4. Installation of aluminum alloy doors and windows in place

Install aluminum alloy door and window frame according to the marked positioning line of doors and windows. And adjust the horizontal, vertical and diagonal length of the door and window frame in time to meet the quality standards, and then temporarily fix it with wooden wedge.

5. Fixing of aluminum alloy doors and windows

(1) When iron parts are embedded on the wall, the iron feet of aluminum alloy doors and windows can be directly welded with the embedded iron parts on the wall, and the welding place needs rust prevention treatment.

(2) when there are no embedded iron parts on the wall, metal expansion bolts or plastic expansion bolts can be used to fix the iron feet of aluminum alloy doors and windows to the wall.

(3) when there are no embedded iron parts on the wall, electric drill can also be used to punch 80mm deep and 6mm diameter holes on the wall, and L-type 80mm × 50mm 6rmn steel bar is used. Stick 108 glue mud on the long end and drive it into the hole. After 108 glue mud is finally solidified, the iron feet of aluminum alloy doors and windows and the embedded 6mm steel bar shall be welded firmly.

6. Treatment of gap between door and window frame and wall

(1) after the installation and fixing of aluminum alloy doors and windows, the concealed engineering acceptance should be carried out first, and the gap between the door and window frame and the wall should be handled timely according to the design requirements after passing the acceptance.

(2) If the design is not required, elastic insulation materials or glass wool felt strips can be used to layer fill plug gaps, and 5~8mm deep notches on the outer surface can be filled with embedded joint ointment or sealant.

7. Installation of door and window fan and door and window glass

1) doors and windows fan and doors and windows glass should be installed after the completion of the opening wall surface finishing.

2) after the sliding doors and windows are installed and fixed in the door and window frame, install the doors and windows with glass into the slide in the frame as a whole, and adjust the gap between the frame and the fan.

3) flat open doors and windows assemble the frame and the fan on the wall grillwork, install and fix it, then install the glass, that is, adjust the gap between the frame and the fan first, then make the glass fan and adjust the position, finally, insert sealing strip and sealant.

4) the floor spring door should be fixed after the door frame and floor spring main engine are installed. First embed the glass into the door leaf grillwork and put the frame together, adjust the gap of the frame leaf, and finally fill in the sealing strip and sealant of the door leaf glass.

8. Construction precautions

1) pay attention to the assembly quality when adopting multiple sets of combined doors and windows. The Assembly head should be flat without cutting edges and corners.

2) during the construction, the product protection must be strictly done, the damaged and dropped protection laminating film and film should be sealed in time, and the mortar dirt splashed on the surface of doors and windows should be removed in time to avoid the pollution and bite of the surface layer of doors and windows.

3) the thickness of the door and window glass should conform to the national standards and design requirements with the size of the fan-inlay groove and sealing strip. When installing the sealing strip, there should be room for expansion to avoid the sealing strip falling off.

News source: door and window maniac