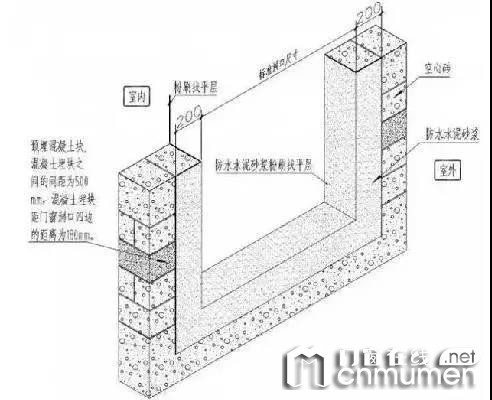

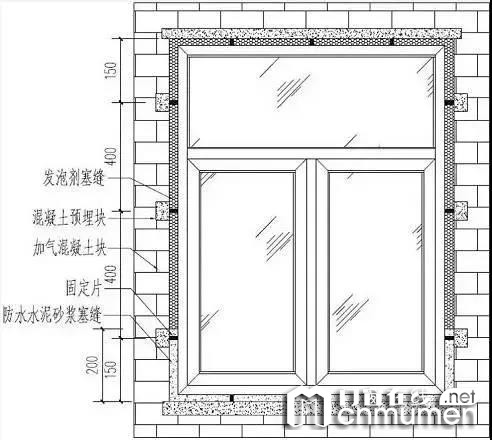

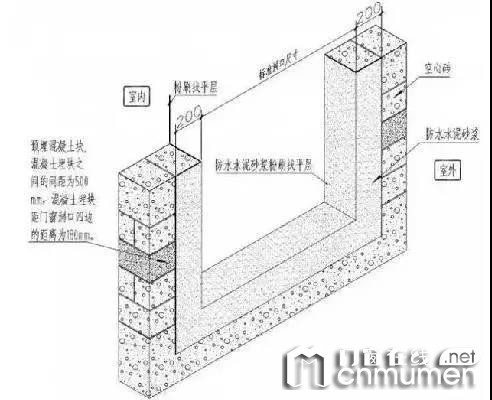

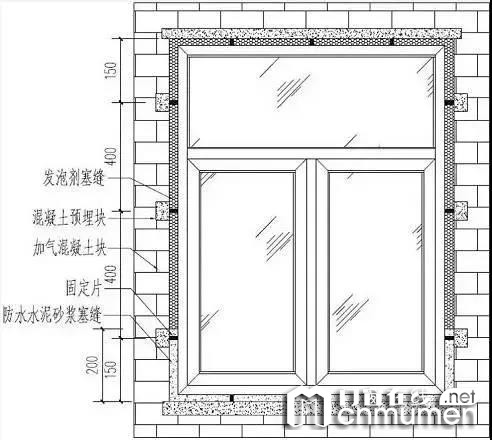

Standard opening size: the opening of doors and windows is completed with foundation masonry, and the final opening size after finishing the first waterproof mortar is the standard size of the opening of doors and windows.

Before installing the window frame

1. A cement mortar should be painted at the opening to make the surface of the opening smooth and the size regular. The outer window sill plate the surface of the substrate should be poured into 3-5% of the outward flooding, and the part that extends into the wall should be slightly higher than the exposed board surface.

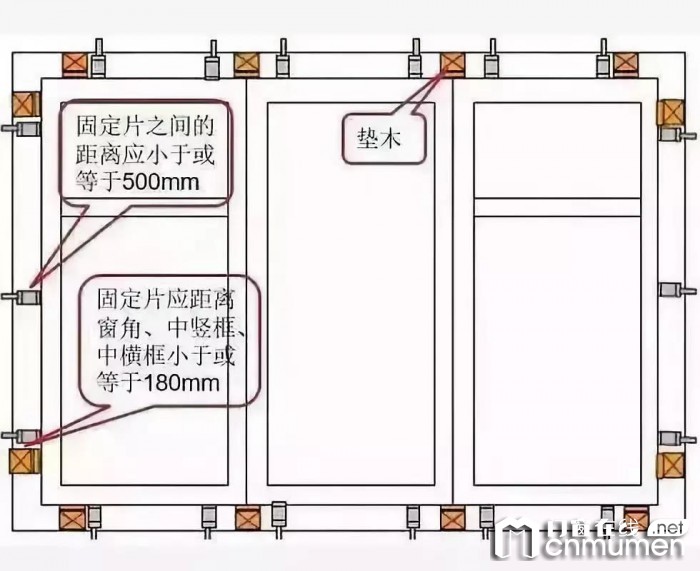

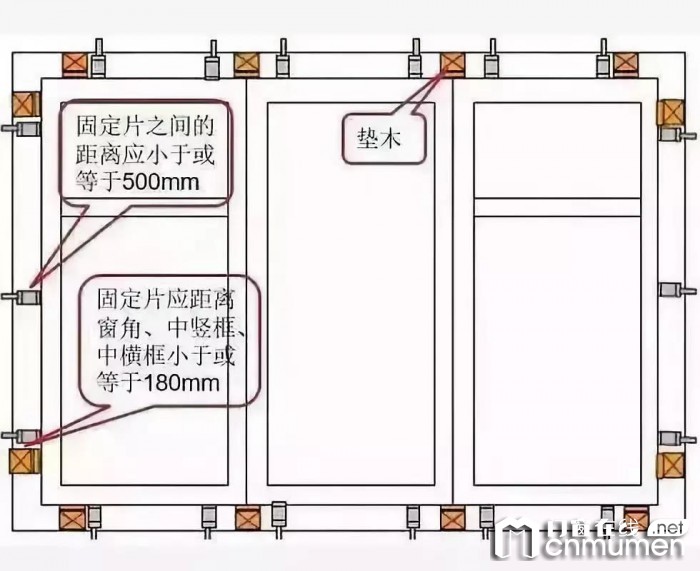

2. Concrete embedded blocks shall be reserved at the opening of doors and windows of brick walls (clay brick and easy-to-pass blocks). The spacing requirements of concrete buried blocks are as follows: the spacing between buried blocks at the upper and lower sides of the opening should be 180mm, and the spacing between buried blocks at the left and right sides of the opening should be 500mm.

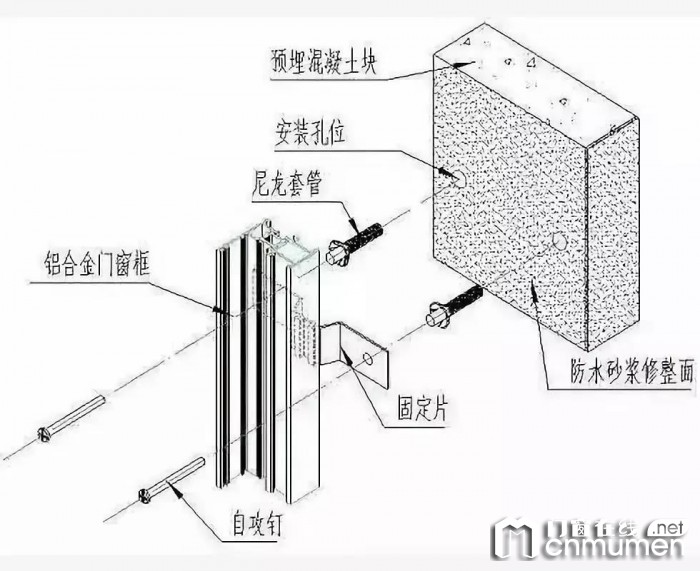

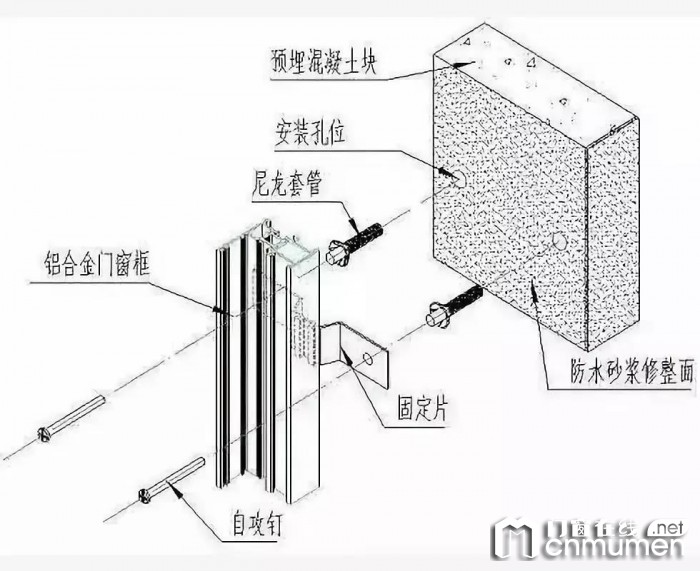

If the hole deviation is greater than 10mm and the hole is trimmed with cement mortar, it is forbidden to use fastener to fix the connection between the door and window fixing piece and the civil structure, and nylon expansion screws should be used to fix the hole.

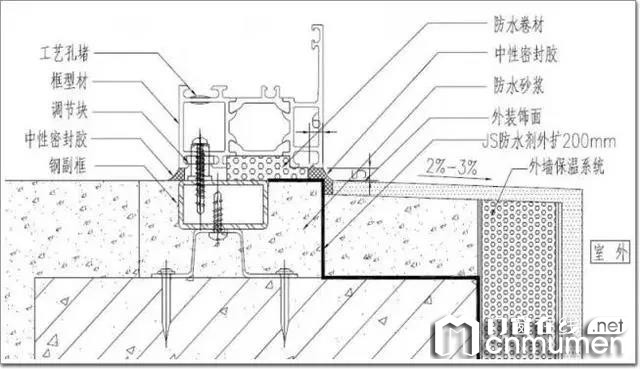

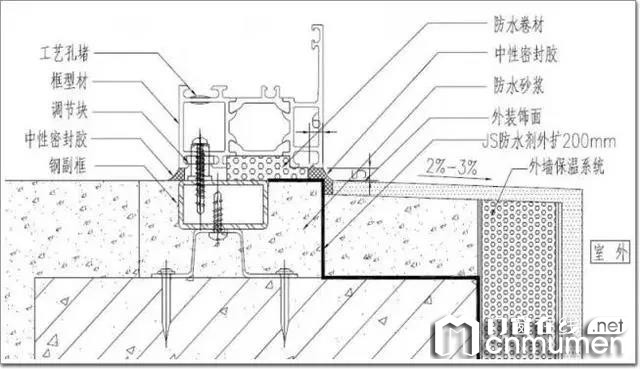

3. The upper and lower ports of the splicing materials should be blocked, and the splicing materials should be designed to be lengthened and reliably connected with the structure. When combining the door (window) frame with the splicing materials card, the fasteners should be tightened in two directions, the spacing should not be greater than 500mm, and the spacing between the two ends should not be greater than 180mm. The gap between the splicing material and the door (window) frame should be sealed with caulking glue.

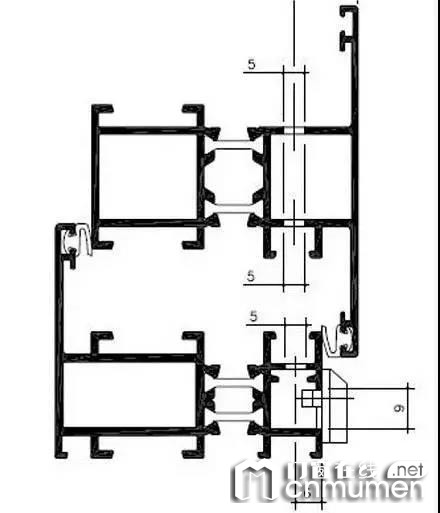

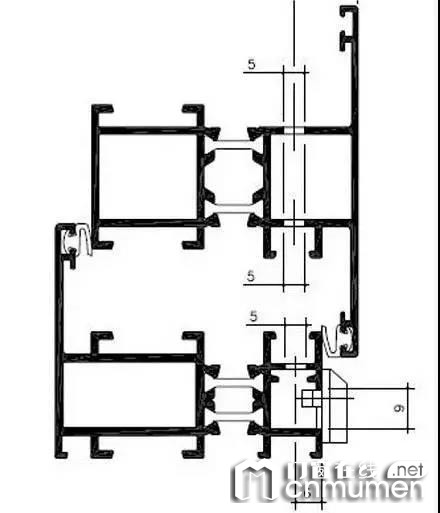

The installation clearance of the main and auxiliary frames should be strictly controlled according to the design clearance of the main and auxiliary frames. After the installation is completed, the actual clearance of the main and auxiliary frames should not be less than 4mm.

The gap control of the main and auxiliary frames should adopt the gap adjustment block of the special main and auxiliary frames, and the gap between the main and auxiliary frames should not be controlled directly by fastening fasteners.

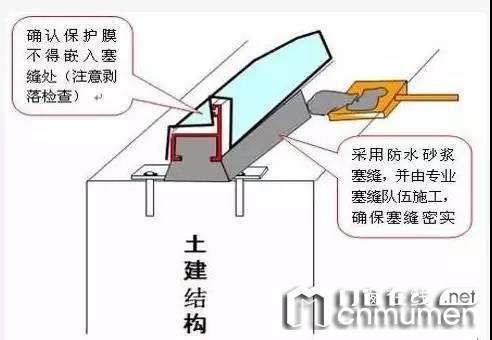

Plug gap is 15~25mm. The minimum construction temperature is +5°C.

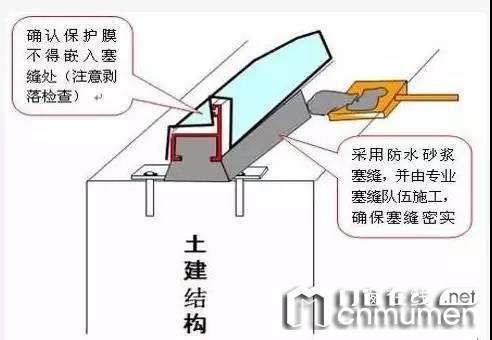

4. Before construction, clean the filling part and spray it with water, spray it from bottom to top, spray the amount to 70% of the filling volume, and the surface will start to solidify in ten minutes, insert the overflow foaming agent into the gap before curing to prevent the foaming agent from being damaged adventitious coat.

5. Waterproof mortar should be used for seaming mortar, regular mixing ratio: cement: Sand: waterproof agent (weight ratio) is 1:2.5:0.03, and the mixing ratio is adjusted according to the usage. Considering the crack resistance, polypropylene fiber-Dura fiber can be added. It is recommended to use a professional sewing team to plug the seam, and the reasonable gap between the plug seam is 15~30mm, reinforcement mesh plate fine stone concrete must be adopted for hole correction greater than 50mm.

Reinforced mesh plate fine stone concrete method

(1) the base surface must be smooth, firm, clean, free of clear water and leakage; Defects such as uneven and cracks must be filled, and the leakage must stop water; The Yin and Yang corners should be made into arc angles.

(2) accurately measure according to the ingredients ratio required by the factory. When mixing ingredients, stir the liquid materials with a blender first, and slowly add the powder to mix and stir under the stirring state (appropriate amount of water can be added to adjust the viscosity, however, it is better to add water before adding the powder). It should be fully stirred and dispersed to achieve uniform without powder mass and precipitation. The prepared materials should be used up within 2 to 3 hours.

(3) according to the selected method, it is completed layer by layer in sequence, and the interval between each layer is subject to the dry and non-stick coating film before. Generally, the construction takes more than 4 hours and the temperature is 20℃. If the temperature is low, the humidity is high, and the ventilation condition is poor, the time will be longer.

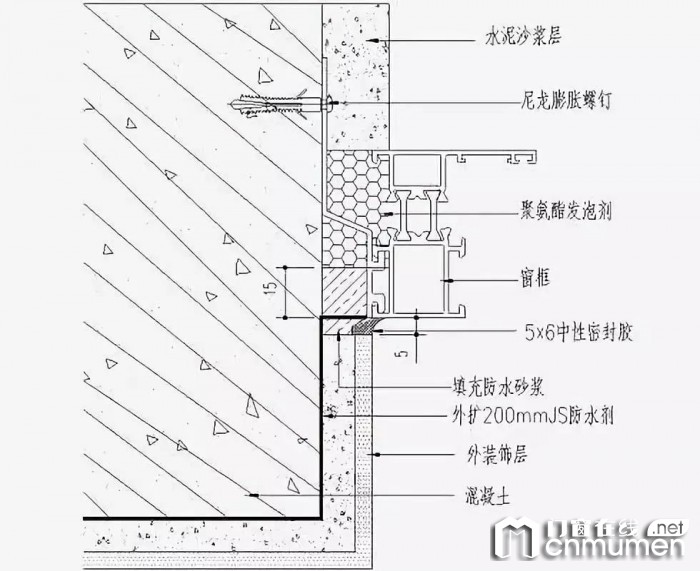

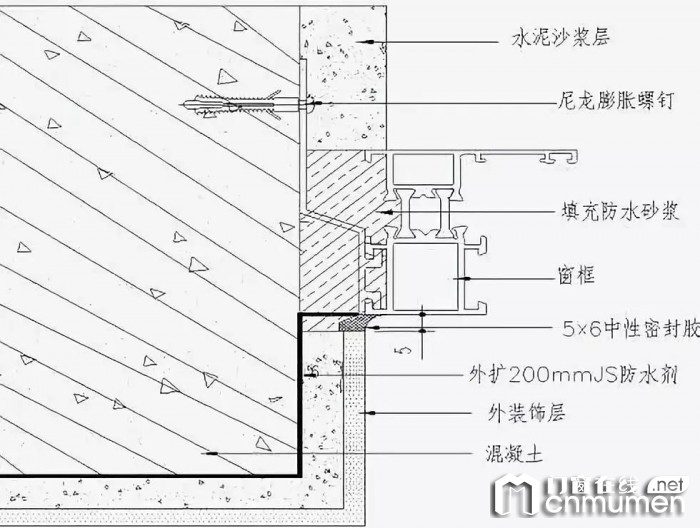

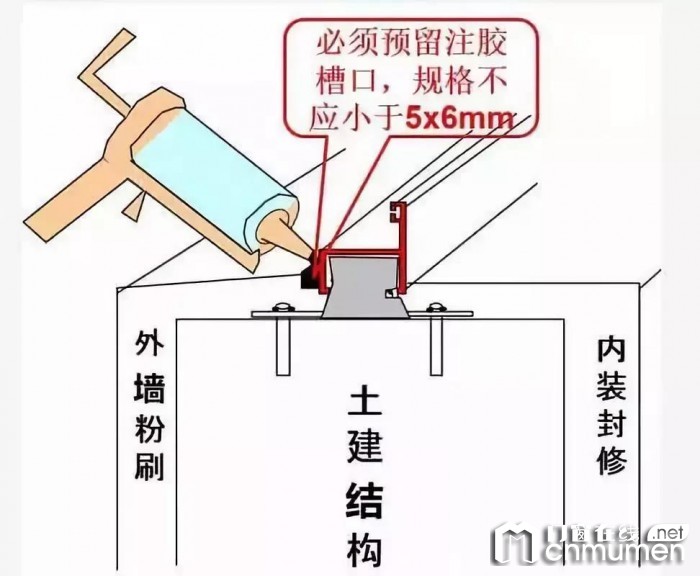

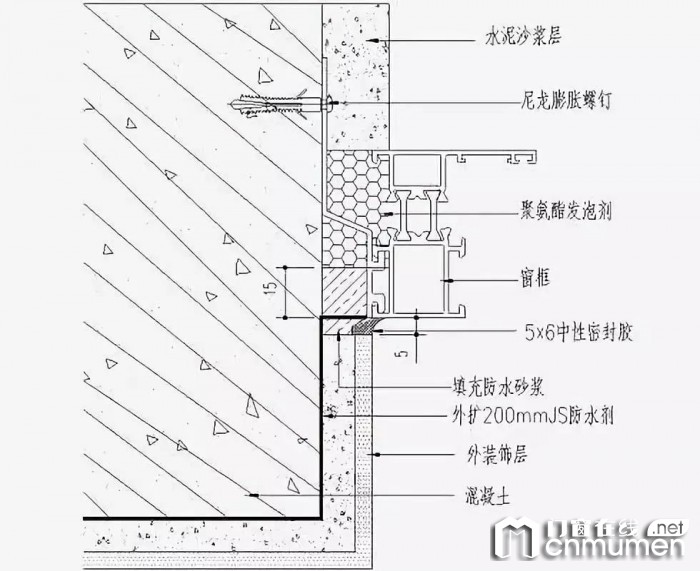

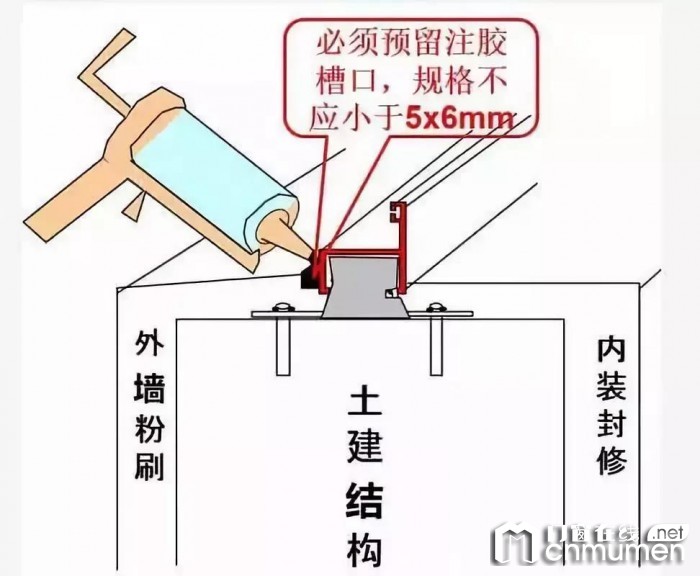

Precautions for construction of outer door and window frame

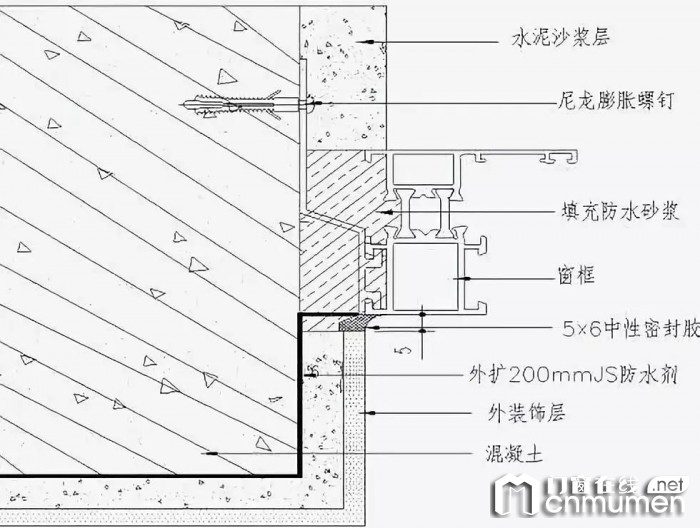

1. The outside of the outer door and window frame must leave 5mm wide and 6mm deep glue injection slot. The glue injection slot can be reserved with PVC type splitting stripe as slot. After the outer paint layer is hardened, the PVC type splitting stripe can be removed. The painted surface should slightly exceed the window frame, and its thickness should not affect the opening of the fan and the drainage of doors and windows.

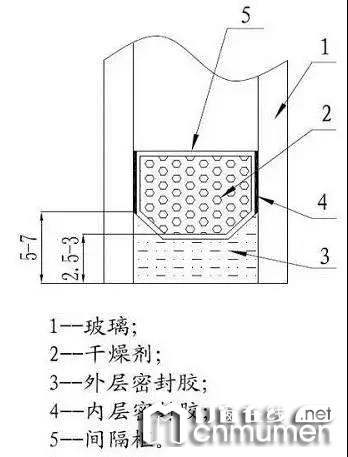

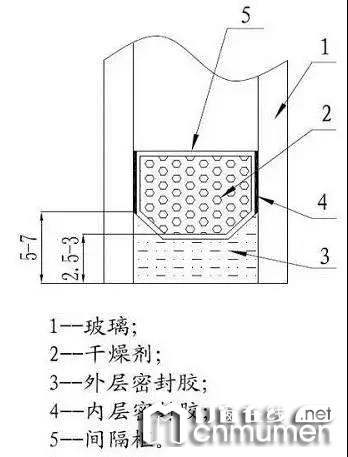

2, external wall glue injection should be clean glue injection slot and base layer, and after drying, apply sealant, should use neutral silicone sealant glue injection seal. It is strictly prohibited to inject sealant on paint topcoat. Neutral silicone glue injection should be full, even and uninterrupted, and the outer sealant layer thickness is 5 ~ 7mm.

3. Low-E glass coating surface must face the hollow layer. When installing, Low-E glass is located on the outdoor side. Tempered glass should be labeled with 3C according to the specifications, double-layer tempered glass should be marked with 3C on both tempered glass.

Precautions for door and window installation

1. Doors and windows must be installed in the repaired doors and windows opening, but the hole deviation exceeds 10mm and the hole is trimmed with cement mortar. The fixing piece shall not be fastened with fastener, and the hole should be fixed with nylon expansion screws.

2. The splicing material shall be designed to be lengthened and effectively fixed with the structure after the port is blocked; The splicing material and combo box shall be fastened in two directions with fasteners, and the splicing position shall be sealed with sealant; the crevice foaming agent should be inserted into the crevice before curing and should not be cut.

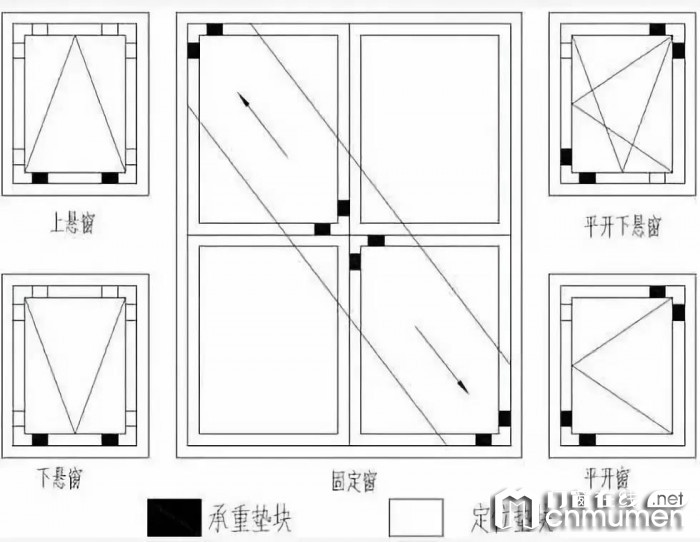

3. It is forbidden to inject sealant on paint topcoat! Before glue injection, the glue injection slot should be cleaned, and the thickness of the outer sealant layer of insulating glass should be 5~7mm; The heavy blocks and limited block of the glass cushion block should be placed as required; hardware fasteners shall be made of stainless steel and fully fastened, and rivets shall not be used anywhere.

If the hole deviation is greater than 10mm and the hole is trimmed with cement mortar, it is forbidden to use fastener to fix the connection between the door and window fixing piece and the civil structure, and nylon expansion screws should be used to fix the hole.

If the hole deviation is greater than 10mm and the hole is trimmed with cement mortar, it is forbidden to use fastener to fix the connection between the door and window fixing piece and the civil structure, and nylon expansion screws should be used to fix the hole.

3. The upper and lower ports of the splicing materials should be blocked, and the splicing materials should be designed to be lengthened and reliably connected with the structure. When combining the door (window) frame with the splicing materials card, the fasteners should be tightened in two directions, the spacing should not be greater than 500mm, and the spacing between the two ends should not be greater than 180mm. The gap between the splicing material and the door (window) frame should be sealed with caulking glue.

3. The upper and lower ports of the splicing materials should be blocked, and the splicing materials should be designed to be lengthened and reliably connected with the structure. When combining the door (window) frame with the splicing materials card, the fasteners should be tightened in two directions, the spacing should not be greater than 500mm, and the spacing between the two ends should not be greater than 180mm. The gap between the splicing material and the door (window) frame should be sealed with caulking glue.

The installation clearance of the main and auxiliary frames should be strictly controlled according to the design clearance of the main and auxiliary frames. After the installation is completed, the actual clearance of the main and auxiliary frames should not be less than 4mm.

The gap control of the main and auxiliary frames should adopt the gap adjustment block of the special main and auxiliary frames, and the gap between the main and auxiliary frames should not be controlled directly by fastening fasteners.

Plug gap is 15~25mm. The minimum construction temperature is +5°C.

The installation clearance of the main and auxiliary frames should be strictly controlled according to the design clearance of the main and auxiliary frames. After the installation is completed, the actual clearance of the main and auxiliary frames should not be less than 4mm.

The gap control of the main and auxiliary frames should adopt the gap adjustment block of the special main and auxiliary frames, and the gap between the main and auxiliary frames should not be controlled directly by fastening fasteners.

Plug gap is 15~25mm. The minimum construction temperature is +5°C.

4. Before construction, clean the filling part and spray it with water, spray it from bottom to top, spray the amount to 70% of the filling volume, and the surface will start to solidify in ten minutes, insert the overflow foaming agent into the gap before curing to prevent the foaming agent from being damaged adventitious coat.

4. Before construction, clean the filling part and spray it with water, spray it from bottom to top, spray the amount to 70% of the filling volume, and the surface will start to solidify in ten minutes, insert the overflow foaming agent into the gap before curing to prevent the foaming agent from being damaged adventitious coat.

5. Waterproof mortar should be used for seaming mortar, regular mixing ratio: cement: Sand: waterproof agent (weight ratio) is 1:2.5:0.03, and the mixing ratio is adjusted according to the usage. Considering the crack resistance, polypropylene fiber-Dura fiber can be added. It is recommended to use a professional sewing team to plug the seam, and the reasonable gap between the plug seam is 15~30mm, reinforcement mesh plate fine stone concrete must be adopted for hole correction greater than 50mm.

5. Waterproof mortar should be used for seaming mortar, regular mixing ratio: cement: Sand: waterproof agent (weight ratio) is 1:2.5:0.03, and the mixing ratio is adjusted according to the usage. Considering the crack resistance, polypropylene fiber-Dura fiber can be added. It is recommended to use a professional sewing team to plug the seam, and the reasonable gap between the plug seam is 15~30mm, reinforcement mesh plate fine stone concrete must be adopted for hole correction greater than 50mm.

Reinforced mesh plate fine stone concrete method

(1) the base surface must be smooth, firm, clean, free of clear water and leakage; Defects such as uneven and cracks must be filled, and the leakage must stop water; The Yin and Yang corners should be made into arc angles.

(2) accurately measure according to the ingredients ratio required by the factory. When mixing ingredients, stir the liquid materials with a blender first, and slowly add the powder to mix and stir under the stirring state (appropriate amount of water can be added to adjust the viscosity, however, it is better to add water before adding the powder). It should be fully stirred and dispersed to achieve uniform without powder mass and precipitation. The prepared materials should be used up within 2 to 3 hours.

(3) according to the selected method, it is completed layer by layer in sequence, and the interval between each layer is subject to the dry and non-stick coating film before. Generally, the construction takes more than 4 hours and the temperature is 20℃. If the temperature is low, the humidity is high, and the ventilation condition is poor, the time will be longer.

Reinforced mesh plate fine stone concrete method

(1) the base surface must be smooth, firm, clean, free of clear water and leakage; Defects such as uneven and cracks must be filled, and the leakage must stop water; The Yin and Yang corners should be made into arc angles.

(2) accurately measure according to the ingredients ratio required by the factory. When mixing ingredients, stir the liquid materials with a blender first, and slowly add the powder to mix and stir under the stirring state (appropriate amount of water can be added to adjust the viscosity, however, it is better to add water before adding the powder). It should be fully stirred and dispersed to achieve uniform without powder mass and precipitation. The prepared materials should be used up within 2 to 3 hours.

(3) according to the selected method, it is completed layer by layer in sequence, and the interval between each layer is subject to the dry and non-stick coating film before. Generally, the construction takes more than 4 hours and the temperature is 20℃. If the temperature is low, the humidity is high, and the ventilation condition is poor, the time will be longer.

Precautions for construction of outer door and window frame

1. The outside of the outer door and window frame must leave 5mm wide and 6mm deep glue injection slot. The glue injection slot can be reserved with PVC type splitting stripe as slot. After the outer paint layer is hardened, the PVC type splitting stripe can be removed. The painted surface should slightly exceed the window frame, and its thickness should not affect the opening of the fan and the drainage of doors and windows.

Precautions for construction of outer door and window frame

1. The outside of the outer door and window frame must leave 5mm wide and 6mm deep glue injection slot. The glue injection slot can be reserved with PVC type splitting stripe as slot. After the outer paint layer is hardened, the PVC type splitting stripe can be removed. The painted surface should slightly exceed the window frame, and its thickness should not affect the opening of the fan and the drainage of doors and windows.

2, external wall glue injection should be clean glue injection slot and base layer, and after drying, apply sealant, should use neutral silicone sealant glue injection seal. It is strictly prohibited to inject sealant on paint topcoat. Neutral silicone glue injection should be full, even and uninterrupted, and the outer sealant layer thickness is 5 ~ 7mm.

3. Low-E glass coating surface must face the hollow layer. When installing, Low-E glass is located on the outdoor side. Tempered glass should be labeled with 3C according to the specifications, double-layer tempered glass should be marked with 3C on both tempered glass.

2, external wall glue injection should be clean glue injection slot and base layer, and after drying, apply sealant, should use neutral silicone sealant glue injection seal. It is strictly prohibited to inject sealant on paint topcoat. Neutral silicone glue injection should be full, even and uninterrupted, and the outer sealant layer thickness is 5 ~ 7mm.

3. Low-E glass coating surface must face the hollow layer. When installing, Low-E glass is located on the outdoor side. Tempered glass should be labeled with 3C according to the specifications, double-layer tempered glass should be marked with 3C on both tempered glass.

Precautions for door and window installation

1. Doors and windows must be installed in the repaired doors and windows opening, but the hole deviation exceeds 10mm and the hole is trimmed with cement mortar. The fixing piece shall not be fastened with fastener, and the hole should be fixed with nylon expansion screws.

2. The splicing material shall be designed to be lengthened and effectively fixed with the structure after the port is blocked; The splicing material and combo box shall be fastened in two directions with fasteners, and the splicing position shall be sealed with sealant; the crevice foaming agent should be inserted into the crevice before curing and should not be cut.

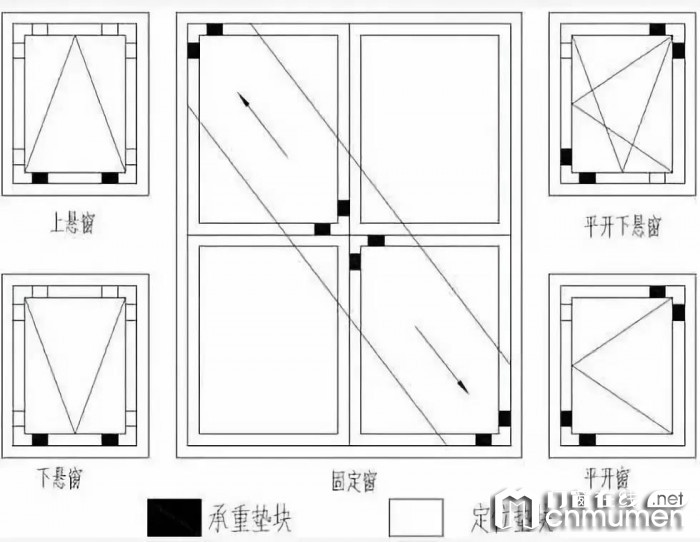

3. It is forbidden to inject sealant on paint topcoat! Before glue injection, the glue injection slot should be cleaned, and the thickness of the outer sealant layer of insulating glass should be 5~7mm; The heavy blocks and limited block of the glass cushion block should be placed as required; hardware fasteners shall be made of stainless steel and fully fastened, and rivets shall not be used anywhere.

Precautions for door and window installation

1. Doors and windows must be installed in the repaired doors and windows opening, but the hole deviation exceeds 10mm and the hole is trimmed with cement mortar. The fixing piece shall not be fastened with fastener, and the hole should be fixed with nylon expansion screws.

2. The splicing material shall be designed to be lengthened and effectively fixed with the structure after the port is blocked; The splicing material and combo box shall be fastened in two directions with fasteners, and the splicing position shall be sealed with sealant; the crevice foaming agent should be inserted into the crevice before curing and should not be cut.

3. It is forbidden to inject sealant on paint topcoat! Before glue injection, the glue injection slot should be cleaned, and the thickness of the outer sealant layer of insulating glass should be 5~7mm; The heavy blocks and limited block of the glass cushion block should be placed as required; hardware fasteners shall be made of stainless steel and fully fastened, and rivets shall not be used anywhere.