You can bathe in the sunshine every morning.

It is a happy thing to wake up lazily.

High working pressure

Make a cup of coffee and stand in front of the windowsill.

A look at the blue sky and white clouds is a good way to relieve emotions.

In today's jungle with concrete reinforced water

Doors and windows become one of our ties to nature.

However, with the improvement of economic level and living standard, people's requirements for doors and windows are not only good lighting and high ventilation, but also thermal insulation, wind pressure resistance, more and more attention has been paid to sound insulation and other properties. Therefore, innovation and upgrading have become eternal topics in the door and window industry. From the earliest wood to the later steel, plastic steel, aluminum alloy doors and windows to the birth of today's aluminum-coated plastic, aluminum-clad wood and other materials, various materials are constantly updated and iterated to make consumers feel overwhelmed. Facing the emergence of various new concept materials, how should consumers choose products that meet their own needs?

Xiao PA will talk with you today about the hot aluminum-coated plastic doors and windows recently.

(Aluminum-coated plastic, 70% plastic composite structure)

What is aluminum-coated plastic doors and windows?

Aluminum-coated plastic doors and windows are made of UPVC resin as the main raw material, aluminum plate is buckled on the outer side, and steel lining is fixed on UPVC through screw connection, and are matched with multiple sealant strips and hardware components, with high technical standards, after repeated tests and verification, it becomes a system door and window with high energy saving. Simply understand, aluminum-coated plastic doors and windows are improved on the basis of plastic steel windows. On the basis of UPVC on the internal facade, aluminum plates with external buckle are adopted. The improved aluminum-coated plastic doors and windows have also stood firm in the market with their own advantages.

(Aluminum-coated plastic doors and windows)

Early thermal insulation performance is better

The low thermal conductivity of plastic is only 1/357 of steel and 1/250 of aluminum, which makes aluminum-coated plastic doors and windows have great advantages in thermal insulation performance. At the same time, double-layer glass or Triplex glass, the multi-cavity profile structure also further improves the thermal insulation performance. With the corresponding sealing technology, aluminum-coated plastic doors and windows have excellent heat insulation performance. Of course, the thermal insulation performance comes from the characteristics of the plastic structure itself, which is determined by the natural non-thermal conductor rather than the profile structure itself. The initial effect is not insignificant, but what changes will happen after 3-5 years of use, the editor will also analyze with you next.

(Aluminum-coated plastic doors and windows)

Changeable appearance

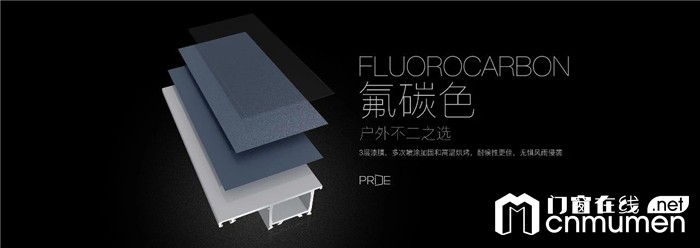

The inner facade of aluminum-coated plastic doors and windows adopts hot melt laminating technology, which is a warm and elegant wood grain window from the indoor perspective and has certain scratch resistance. The outer side buckle aluminum plate, by adopting powder spraying or fluorocarbon technology, the outdoor side has a changeable style. Aluminum-coated plastic doors and windows can not only meet the different requirements of building inner and outer sides doors and windows materials, but also meet the customized needs of consumers.

In addition to the continuation of the better thermal insulation performance of plastic steel doors and windows, while absorbing the customized configuration of aluminum alloy doors and windows with changeable colors, does the aluminum-coated plastic doors and windows with perfect performance have no shortcomings? The following small editor will show you the truth!

Low hardness, high cost, fault fracture, serious after-sales

Aluminum coated plastic doors and windows:

Main part material the steel property of UPVC resin is insufficient. Although aluminum buckle is used externally and steel lining is added internally, the hardness of the profile has been greatly improved, but the fact that the steel property of UPVC resin main part material is insufficient cannot be ignored, even some unscrupulous manufacturers reduce the usage by steel lining in order to reduce costs, resulting in insufficient wind pressure resistance of the whole window. And the splicing angle is welded by plastic, resulting in the angular strength not exceeding 50KN, resulting in 45 ° splicing angle easily causing dislocation, affecting the structural strength of the whole window, at the same time, there are congenital deficiencies in the installation firmness of hardware accessories. Because the hardness is not high, it is easy to pull explosion, fracture and fault in the process of production and installation, so the production cost is very high, and gravity impact Pat occurs during installation or transportation, the internal plastic structure will be broken, the structure is misaligned and the structure is unstable, so there is no problem of sound insulation and heat insulation at all.

PA laide doors and windows:

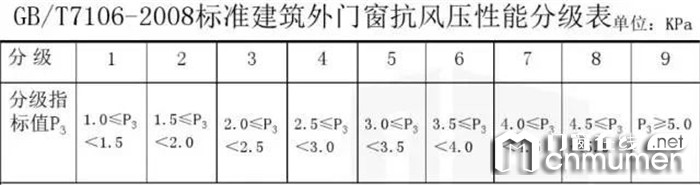

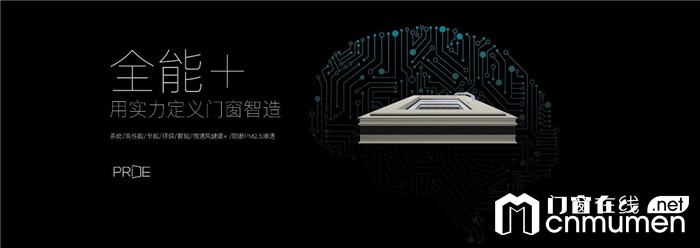

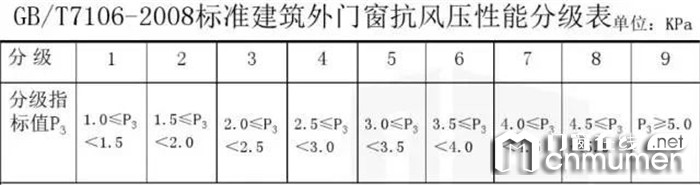

Main part material is mainly made of aluminum, and metal elements such as magnesium, manganese and chromium are added at the same time. The material strength of aluminum alloy itself is incomparable to that of PVC. In addition, specially designed toothed hardware channels (such as European standard slots), its reliability is higher. PA laide doors and windows are made of high-density aluminum profiles, combined with high-strength tempered glass, which can reach the highest level of wind pressure resistance of grade 9 in the country. PA laide 6063-T6 aluminum alloy used by doors and windows is widely used in the frame of building aluminum doors and windows and curtain walls, and is a rare aluminum alloy model. It is cooled by the high-temperature molding process and then subjected to artificial aging. Aluminum Alloy with magnesium and silicon as main alloy elements and Mg2Si mutually strengthened.

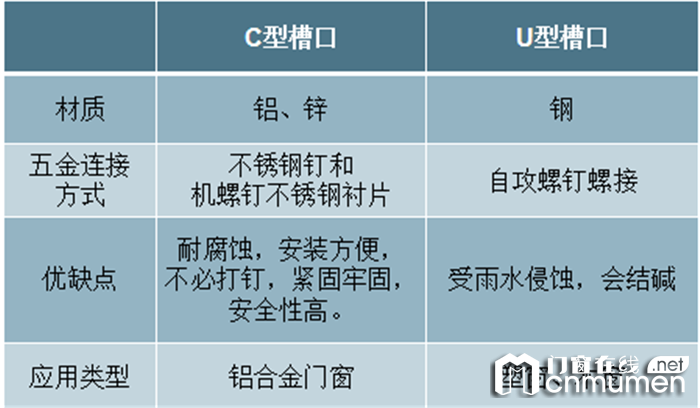

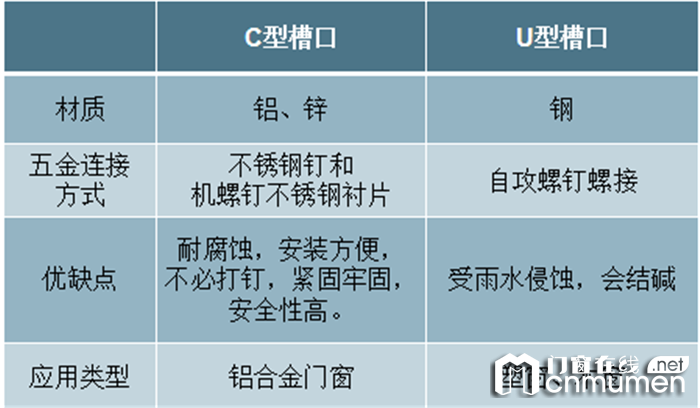

There are two types of hardware notches in aluminum alloy door and window profile of China: U-shaped and C- shaped, and PA laide C- type hardware notches with more advanced design principles for doors and windows. The C- type slot-port hardware installation stainless steel nail will be tightened on the surface of the profile, resulting in local deformation of about 0.5-1.0mm, which will tightly combine the stainless steel nail with the aluminum profile. Standard C- slot hardware exchange performance is good, easy for after-sales maintenance, some manufacturers special slot, need to use exclusive hardware will cause after-sales difficulties.

When choosing doors and windows, everyone has their own first consideration factors, such as sound insulation effect and heat insulation effect. But what is most easily overlooked is the safety performance of doors and windows. Under the premise that the safety performance and after-sales service cannot be guaranteed, how can we talk about other performance?

Reduced sound insulation performance

Aluminum coated plastic doors and windows:

Effectively restrain the structural resonance and coincidence effect, theoretically the sound conductivity of plastic is lower than that of aluminum alloy profile. However, it is easy for people to ignore many problems of performance decline caused by aging of plastic profiles. When plastic profiles are in relatively bad weather environment for a long time, deformation, brittleness and unstable size are easy to occur, while the outer side buckle aluminum plate is not easy to distinguish the changes of the internal structure, and the sealing effect will become worse for a long time, which will lead to the deterioration of the sound insulation effect, at the same time, the aging phenomenon of internal plastic profiles will also increase the risk of further decline of wind pressure resistance.

PA laide doors and windows:

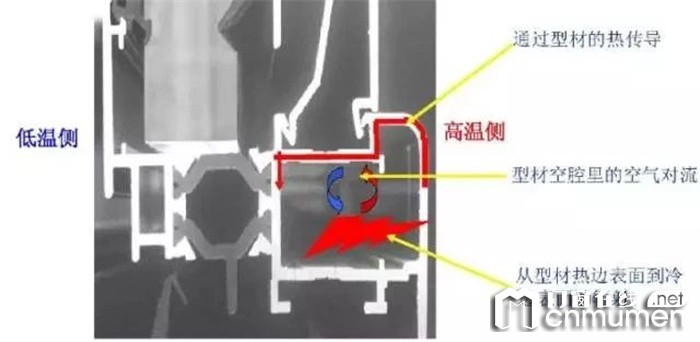

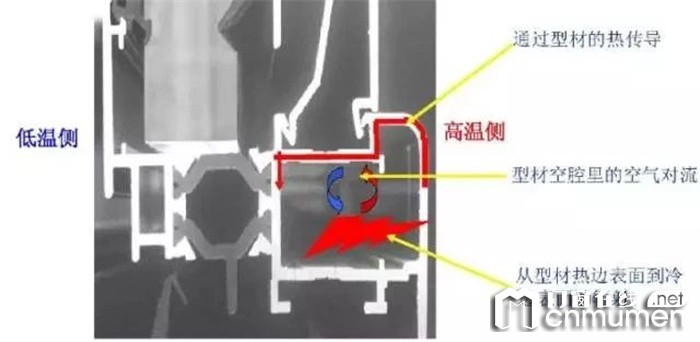

Simply put, the Tylenol-style heat insulation profile used for PA laide doors and windows can achieve the following effects:

1. The heat conduction, radiation and air convection in the cavity through the profile only account for 5%-10% of the heat flow; 2. Thermal conductivity of standard Tylenol wind insulation strip: 0.3W/m k;

3. A two-color system must be formed through a series of rigorous processes of hobbing, threading and rolling; 4.≥ 220℃ Thermal Deformation temperature, blocking heat and maintaining heat at the same time to prevent profile softening; 5. Complex aluminum structure can be combined, and multiple heat insulation strips show energy saving effect; 6. The glass, heat insulation strip and sealing strip are on the same isotherm, and CT-type multi-cavity complex shapes appear; The watertight and airtight wind pressure resistance performance is reduced

Aluminum coated plastic doors and windows:

Since aluminum-coated plastic doors and windows have been improved on the basis of plastic steel windows, and the water seepage rate of plastic steel itself is very high. If plastic structure is adopted on the basis of plastic steel, the water seepage rate will be greatly enhanced. At the same time, due to the low service life of the plastic, the weather is exposed to the sun or frozen for a long time, causing internal structural faults, and the water vapor and mist directly enter the glass or pass through the external aluminum gusset. For example, Guangdong is a place that can experience four seasons a day. Through the alternation of cold and heat, heavy rain and high temperature water vapor evaporate, coupled with a crazy beating of Grandpa Fengshen, the terrible scene editor will not elaborate with you, self-brain repair.

PA laide doors and windows:

In recent PA laide years, after accompanying us through the wind King "mangosteen" and the wind spirit "Flying Pigeon", we can see that we are not the same, what is the difference? Different sound insulation, different heat insulation, different noise reduction, different glue, different hardware, different profiles, different sealing, and different craftsmanship. Only 140 to the processing process, eight heavy glass production process, etc., the small editor can put some low-end products to doubt life.

Short service life

Aluminum coated plastic doors and windows:

The facade adopts aluminum profiles, which are powder sprayed or fluorocarbon sprayed and have strong weather resistance. Although some UV and infrared rays are shielded from the radiation of plastic profiles, the hidden danger of aging of plastic profiles cannot be solved. Plastic profiles themselves are easily deformed, cold and brittle, poor dimensional stability, and toxic gases will be emitted when plastic profiles are burning. Due to the characteristics of plastic profiles, the service life of aluminum-coated plastic doors and windows is greatly reduced.

PA laide doors and windows:

Light weight, high structural strength and small deformation. Through surface treatment technology, it has excellent fading resistance, corrosion resistance and crack resistance, and can withstand severe weather environment. Combined with various conditions, the service life of aluminum alloy doors and windows is as high as 30 years or more. PA Laide is a very small number of brands in the industry that own surface treatment technologies such as water-based paint spraying imported from wood grain to British. High-definition wood grain technology and rubber strip foaming technology are second to none in the industry, double angle code mechanical angle set technology ensures that both aesthetics and functionality complement each other; The self-developed standardized workbench has strict data, processes and indicators for monitoring in every process, make every set of customized doors and windows can meet the requirements of high-performance system doors and windows, which greatly enhances the core competitiveness of products.

Low utilization rate of environmental protection

Aluminum coated plastic doors and windows:

If the service life is not long, once installed, the recycling value is low, and main part material UPVC resin cannot be degraded, which causes great problems to environmental protection. If the black commercial waste PVC furnace is recast, the damage is N times larger than that of aluminum alloy waste. Once it enters the market, the situation is unimaginable.

PA laide doors and windows:

It is not easy to age, even after several years, the recycling value of aluminum is still very high, which can be repeatedly refined and recycled. Even if it can be reused, pa laide is still made with the most original native aluminum ingot, which is far from the difference between strength and surface color.

Aluminum-coated plastic doors and windows are widely loved by consumers because of their excellent thermal insulation and energy saving performance. However, due to the short development time, there are still some shortcomings. Aluminum alloy doors and windows are still the mainstream in the door and window market. Aluminum alloy doors and windows have gone through 30 years from no one cares about them to becoming mainstream products in the door and window market. In these 30 years, a generation of doors and windows have been working hard at night, overcoming one technical problem after another, only then has the current market position of aluminum alloy doors and windows been achieved.

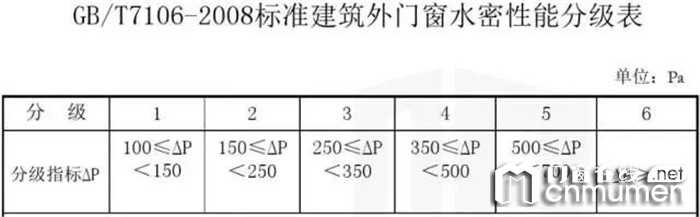

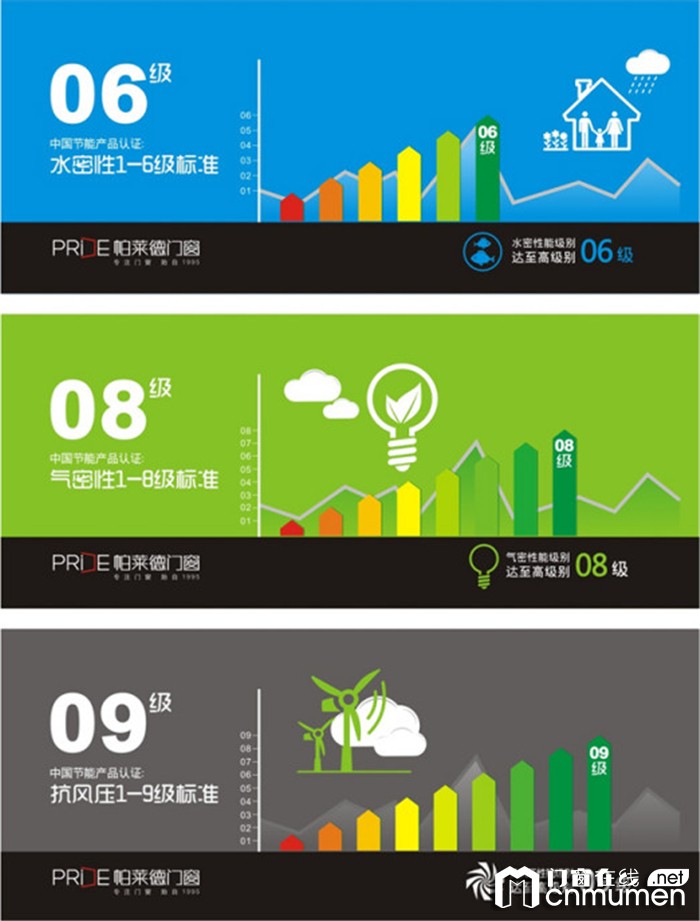

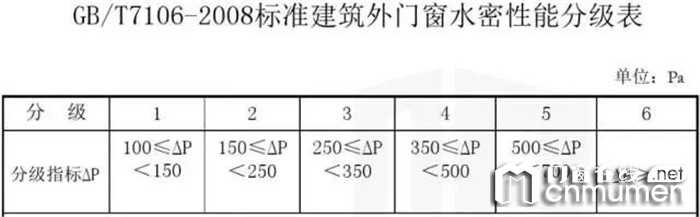

Similarly, PA laide doors and windows have experienced 24 years from scratch, from scratch to precision; Level 1 sun shade, Level 6 water tightness, Level 8 air tightness, Level 9 wind pressure resistance, each performance of the product has reached the highest level of national performance evaluation. In the future, pa laide doors and windows will require themselves with higher standards and strive to become a benchmark brand in the door and window industry!

The birth of various new concept materials

This shows that the door and window industry is developing vigorously.

While innovating and upgrading

The original intention, originality and perseverance should be maintained.

The market is the only standard for testing products.

There is a long way to go, and I will go up and down for help.

Let's wait and see!

Edit: doors and windows online-berries

Xiao PA will talk with you today about the hot aluminum-coated plastic doors and windows recently.

Xiao PA will talk with you today about the hot aluminum-coated plastic doors and windows recently.

(Aluminum-coated plastic, 70% plastic composite structure)

What is aluminum-coated plastic doors and windows?

Aluminum-coated plastic doors and windows are made of UPVC resin as the main raw material, aluminum plate is buckled on the outer side, and steel lining is fixed on UPVC through screw connection, and are matched with multiple sealant strips and hardware components, with high technical standards, after repeated tests and verification, it becomes a system door and window with high energy saving. Simply understand, aluminum-coated plastic doors and windows are improved on the basis of plastic steel windows. On the basis of UPVC on the internal facade, aluminum plates with external buckle are adopted. The improved aluminum-coated plastic doors and windows have also stood firm in the market with their own advantages.

(Aluminum-coated plastic, 70% plastic composite structure)

What is aluminum-coated plastic doors and windows?

Aluminum-coated plastic doors and windows are made of UPVC resin as the main raw material, aluminum plate is buckled on the outer side, and steel lining is fixed on UPVC through screw connection, and are matched with multiple sealant strips and hardware components, with high technical standards, after repeated tests and verification, it becomes a system door and window with high energy saving. Simply understand, aluminum-coated plastic doors and windows are improved on the basis of plastic steel windows. On the basis of UPVC on the internal facade, aluminum plates with external buckle are adopted. The improved aluminum-coated plastic doors and windows have also stood firm in the market with their own advantages.

(Aluminum-coated plastic doors and windows)

Early thermal insulation performance is better

The low thermal conductivity of plastic is only 1/357 of steel and 1/250 of aluminum, which makes aluminum-coated plastic doors and windows have great advantages in thermal insulation performance. At the same time, double-layer glass or Triplex glass, the multi-cavity profile structure also further improves the thermal insulation performance. With the corresponding sealing technology, aluminum-coated plastic doors and windows have excellent heat insulation performance. Of course, the thermal insulation performance comes from the characteristics of the plastic structure itself, which is determined by the natural non-thermal conductor rather than the profile structure itself. The initial effect is not insignificant, but what changes will happen after 3-5 years of use, the editor will also analyze with you next.

(Aluminum-coated plastic doors and windows)

Early thermal insulation performance is better

The low thermal conductivity of plastic is only 1/357 of steel and 1/250 of aluminum, which makes aluminum-coated plastic doors and windows have great advantages in thermal insulation performance. At the same time, double-layer glass or Triplex glass, the multi-cavity profile structure also further improves the thermal insulation performance. With the corresponding sealing technology, aluminum-coated plastic doors and windows have excellent heat insulation performance. Of course, the thermal insulation performance comes from the characteristics of the plastic structure itself, which is determined by the natural non-thermal conductor rather than the profile structure itself. The initial effect is not insignificant, but what changes will happen after 3-5 years of use, the editor will also analyze with you next.

(Aluminum-coated plastic doors and windows)

Changeable appearance

The inner facade of aluminum-coated plastic doors and windows adopts hot melt laminating technology, which is a warm and elegant wood grain window from the indoor perspective and has certain scratch resistance. The outer side buckle aluminum plate, by adopting powder spraying or fluorocarbon technology, the outdoor side has a changeable style. Aluminum-coated plastic doors and windows can not only meet the different requirements of building inner and outer sides doors and windows materials, but also meet the customized needs of consumers.

In addition to the continuation of the better thermal insulation performance of plastic steel doors and windows, while absorbing the customized configuration of aluminum alloy doors and windows with changeable colors, does the aluminum-coated plastic doors and windows with perfect performance have no shortcomings? The following small editor will show you the truth!

Low hardness, high cost, fault fracture, serious after-sales

(Aluminum-coated plastic doors and windows)

Changeable appearance

The inner facade of aluminum-coated plastic doors and windows adopts hot melt laminating technology, which is a warm and elegant wood grain window from the indoor perspective and has certain scratch resistance. The outer side buckle aluminum plate, by adopting powder spraying or fluorocarbon technology, the outdoor side has a changeable style. Aluminum-coated plastic doors and windows can not only meet the different requirements of building inner and outer sides doors and windows materials, but also meet the customized needs of consumers.

In addition to the continuation of the better thermal insulation performance of plastic steel doors and windows, while absorbing the customized configuration of aluminum alloy doors and windows with changeable colors, does the aluminum-coated plastic doors and windows with perfect performance have no shortcomings? The following small editor will show you the truth!

Low hardness, high cost, fault fracture, serious after-sales

Aluminum coated plastic doors and windows:

Main part material the steel property of UPVC resin is insufficient. Although aluminum buckle is used externally and steel lining is added internally, the hardness of the profile has been greatly improved, but the fact that the steel property of UPVC resin main part material is insufficient cannot be ignored, even some unscrupulous manufacturers reduce the usage by steel lining in order to reduce costs, resulting in insufficient wind pressure resistance of the whole window. And the splicing angle is welded by plastic, resulting in the angular strength not exceeding 50KN, resulting in 45 ° splicing angle easily causing dislocation, affecting the structural strength of the whole window, at the same time, there are congenital deficiencies in the installation firmness of hardware accessories. Because the hardness is not high, it is easy to pull explosion, fracture and fault in the process of production and installation, so the production cost is very high, and gravity impact Pat occurs during installation or transportation, the internal plastic structure will be broken, the structure is misaligned and the structure is unstable, so there is no problem of sound insulation and heat insulation at all.

PA laide doors and windows:

Main part material is mainly made of aluminum, and metal elements such as magnesium, manganese and chromium are added at the same time. The material strength of aluminum alloy itself is incomparable to that of PVC. In addition, specially designed toothed hardware channels (such as European standard slots), its reliability is higher. PA laide doors and windows are made of high-density aluminum profiles, combined with high-strength tempered glass, which can reach the highest level of wind pressure resistance of grade 9 in the country. PA laide 6063-T6 aluminum alloy used by doors and windows is widely used in the frame of building aluminum doors and windows and curtain walls, and is a rare aluminum alloy model. It is cooled by the high-temperature molding process and then subjected to artificial aging. Aluminum Alloy with magnesium and silicon as main alloy elements and Mg2Si mutually strengthened.

Aluminum coated plastic doors and windows:

Main part material the steel property of UPVC resin is insufficient. Although aluminum buckle is used externally and steel lining is added internally, the hardness of the profile has been greatly improved, but the fact that the steel property of UPVC resin main part material is insufficient cannot be ignored, even some unscrupulous manufacturers reduce the usage by steel lining in order to reduce costs, resulting in insufficient wind pressure resistance of the whole window. And the splicing angle is welded by plastic, resulting in the angular strength not exceeding 50KN, resulting in 45 ° splicing angle easily causing dislocation, affecting the structural strength of the whole window, at the same time, there are congenital deficiencies in the installation firmness of hardware accessories. Because the hardness is not high, it is easy to pull explosion, fracture and fault in the process of production and installation, so the production cost is very high, and gravity impact Pat occurs during installation or transportation, the internal plastic structure will be broken, the structure is misaligned and the structure is unstable, so there is no problem of sound insulation and heat insulation at all.

PA laide doors and windows:

Main part material is mainly made of aluminum, and metal elements such as magnesium, manganese and chromium are added at the same time. The material strength of aluminum alloy itself is incomparable to that of PVC. In addition, specially designed toothed hardware channels (such as European standard slots), its reliability is higher. PA laide doors and windows are made of high-density aluminum profiles, combined with high-strength tempered glass, which can reach the highest level of wind pressure resistance of grade 9 in the country. PA laide 6063-T6 aluminum alloy used by doors and windows is widely used in the frame of building aluminum doors and windows and curtain walls, and is a rare aluminum alloy model. It is cooled by the high-temperature molding process and then subjected to artificial aging. Aluminum Alloy with magnesium and silicon as main alloy elements and Mg2Si mutually strengthened.

There are two types of hardware notches in aluminum alloy door and window profile of China: U-shaped and C- shaped, and PA laide C- type hardware notches with more advanced design principles for doors and windows. The C- type slot-port hardware installation stainless steel nail will be tightened on the surface of the profile, resulting in local deformation of about 0.5-1.0mm, which will tightly combine the stainless steel nail with the aluminum profile. Standard C- slot hardware exchange performance is good, easy for after-sales maintenance, some manufacturers special slot, need to use exclusive hardware will cause after-sales difficulties.

When choosing doors and windows, everyone has their own first consideration factors, such as sound insulation effect and heat insulation effect. But what is most easily overlooked is the safety performance of doors and windows. Under the premise that the safety performance and after-sales service cannot be guaranteed, how can we talk about other performance?

Reduced sound insulation performance

Aluminum coated plastic doors and windows:

Effectively restrain the structural resonance and coincidence effect, theoretically the sound conductivity of plastic is lower than that of aluminum alloy profile. However, it is easy for people to ignore many problems of performance decline caused by aging of plastic profiles. When plastic profiles are in relatively bad weather environment for a long time, deformation, brittleness and unstable size are easy to occur, while the outer side buckle aluminum plate is not easy to distinguish the changes of the internal structure, and the sealing effect will become worse for a long time, which will lead to the deterioration of the sound insulation effect, at the same time, the aging phenomenon of internal plastic profiles will also increase the risk of further decline of wind pressure resistance.

There are two types of hardware notches in aluminum alloy door and window profile of China: U-shaped and C- shaped, and PA laide C- type hardware notches with more advanced design principles for doors and windows. The C- type slot-port hardware installation stainless steel nail will be tightened on the surface of the profile, resulting in local deformation of about 0.5-1.0mm, which will tightly combine the stainless steel nail with the aluminum profile. Standard C- slot hardware exchange performance is good, easy for after-sales maintenance, some manufacturers special slot, need to use exclusive hardware will cause after-sales difficulties.

When choosing doors and windows, everyone has their own first consideration factors, such as sound insulation effect and heat insulation effect. But what is most easily overlooked is the safety performance of doors and windows. Under the premise that the safety performance and after-sales service cannot be guaranteed, how can we talk about other performance?

Reduced sound insulation performance

Aluminum coated plastic doors and windows:

Effectively restrain the structural resonance and coincidence effect, theoretically the sound conductivity of plastic is lower than that of aluminum alloy profile. However, it is easy for people to ignore many problems of performance decline caused by aging of plastic profiles. When plastic profiles are in relatively bad weather environment for a long time, deformation, brittleness and unstable size are easy to occur, while the outer side buckle aluminum plate is not easy to distinguish the changes of the internal structure, and the sealing effect will become worse for a long time, which will lead to the deterioration of the sound insulation effect, at the same time, the aging phenomenon of internal plastic profiles will also increase the risk of further decline of wind pressure resistance.

PA laide doors and windows:

PA laide doors and windows:

Simply put, the Tylenol-style heat insulation profile used for PA laide doors and windows can achieve the following effects:

1. The heat conduction, radiation and air convection in the cavity through the profile only account for 5%-10% of the heat flow; 2. Thermal conductivity of standard Tylenol wind insulation strip: 0.3W/m k;

3. A two-color system must be formed through a series of rigorous processes of hobbing, threading and rolling; 4.≥ 220℃ Thermal Deformation temperature, blocking heat and maintaining heat at the same time to prevent profile softening; 5. Complex aluminum structure can be combined, and multiple heat insulation strips show energy saving effect; 6. The glass, heat insulation strip and sealing strip are on the same isotherm, and CT-type multi-cavity complex shapes appear; The watertight and airtight wind pressure resistance performance is reduced

Aluminum coated plastic doors and windows:

Since aluminum-coated plastic doors and windows have been improved on the basis of plastic steel windows, and the water seepage rate of plastic steel itself is very high. If plastic structure is adopted on the basis of plastic steel, the water seepage rate will be greatly enhanced. At the same time, due to the low service life of the plastic, the weather is exposed to the sun or frozen for a long time, causing internal structural faults, and the water vapor and mist directly enter the glass or pass through the external aluminum gusset. For example, Guangdong is a place that can experience four seasons a day. Through the alternation of cold and heat, heavy rain and high temperature water vapor evaporate, coupled with a crazy beating of Grandpa Fengshen, the terrible scene editor will not elaborate with you, self-brain repair.

PA laide doors and windows:

In recent PA laide years, after accompanying us through the wind King "mangosteen" and the wind spirit "Flying Pigeon", we can see that we are not the same, what is the difference? Different sound insulation, different heat insulation, different noise reduction, different glue, different hardware, different profiles, different sealing, and different craftsmanship. Only 140 to the processing process, eight heavy glass production process, etc., the small editor can put some low-end products to doubt life.

Simply put, the Tylenol-style heat insulation profile used for PA laide doors and windows can achieve the following effects:

1. The heat conduction, radiation and air convection in the cavity through the profile only account for 5%-10% of the heat flow; 2. Thermal conductivity of standard Tylenol wind insulation strip: 0.3W/m k;

3. A two-color system must be formed through a series of rigorous processes of hobbing, threading and rolling; 4.≥ 220℃ Thermal Deformation temperature, blocking heat and maintaining heat at the same time to prevent profile softening; 5. Complex aluminum structure can be combined, and multiple heat insulation strips show energy saving effect; 6. The glass, heat insulation strip and sealing strip are on the same isotherm, and CT-type multi-cavity complex shapes appear; The watertight and airtight wind pressure resistance performance is reduced

Aluminum coated plastic doors and windows:

Since aluminum-coated plastic doors and windows have been improved on the basis of plastic steel windows, and the water seepage rate of plastic steel itself is very high. If plastic structure is adopted on the basis of plastic steel, the water seepage rate will be greatly enhanced. At the same time, due to the low service life of the plastic, the weather is exposed to the sun or frozen for a long time, causing internal structural faults, and the water vapor and mist directly enter the glass or pass through the external aluminum gusset. For example, Guangdong is a place that can experience four seasons a day. Through the alternation of cold and heat, heavy rain and high temperature water vapor evaporate, coupled with a crazy beating of Grandpa Fengshen, the terrible scene editor will not elaborate with you, self-brain repair.

PA laide doors and windows:

In recent PA laide years, after accompanying us through the wind King "mangosteen" and the wind spirit "Flying Pigeon", we can see that we are not the same, what is the difference? Different sound insulation, different heat insulation, different noise reduction, different glue, different hardware, different profiles, different sealing, and different craftsmanship. Only 140 to the processing process, eight heavy glass production process, etc., the small editor can put some low-end products to doubt life.

Short service life

Short service life

Aluminum coated plastic doors and windows:

The facade adopts aluminum profiles, which are powder sprayed or fluorocarbon sprayed and have strong weather resistance. Although some UV and infrared rays are shielded from the radiation of plastic profiles, the hidden danger of aging of plastic profiles cannot be solved. Plastic profiles themselves are easily deformed, cold and brittle, poor dimensional stability, and toxic gases will be emitted when plastic profiles are burning. Due to the characteristics of plastic profiles, the service life of aluminum-coated plastic doors and windows is greatly reduced.

PA laide doors and windows:

Light weight, high structural strength and small deformation. Through surface treatment technology, it has excellent fading resistance, corrosion resistance and crack resistance, and can withstand severe weather environment. Combined with various conditions, the service life of aluminum alloy doors and windows is as high as 30 years or more. PA Laide is a very small number of brands in the industry that own surface treatment technologies such as water-based paint spraying imported from wood grain to British. High-definition wood grain technology and rubber strip foaming technology are second to none in the industry, double angle code mechanical angle set technology ensures that both aesthetics and functionality complement each other; The self-developed standardized workbench has strict data, processes and indicators for monitoring in every process, make every set of customized doors and windows can meet the requirements of high-performance system doors and windows, which greatly enhances the core competitiveness of products.

Low utilization rate of environmental protection

Aluminum coated plastic doors and windows:

The facade adopts aluminum profiles, which are powder sprayed or fluorocarbon sprayed and have strong weather resistance. Although some UV and infrared rays are shielded from the radiation of plastic profiles, the hidden danger of aging of plastic profiles cannot be solved. Plastic profiles themselves are easily deformed, cold and brittle, poor dimensional stability, and toxic gases will be emitted when plastic profiles are burning. Due to the characteristics of plastic profiles, the service life of aluminum-coated plastic doors and windows is greatly reduced.

PA laide doors and windows:

Light weight, high structural strength and small deformation. Through surface treatment technology, it has excellent fading resistance, corrosion resistance and crack resistance, and can withstand severe weather environment. Combined with various conditions, the service life of aluminum alloy doors and windows is as high as 30 years or more. PA Laide is a very small number of brands in the industry that own surface treatment technologies such as water-based paint spraying imported from wood grain to British. High-definition wood grain technology and rubber strip foaming technology are second to none in the industry, double angle code mechanical angle set technology ensures that both aesthetics and functionality complement each other; The self-developed standardized workbench has strict data, processes and indicators for monitoring in every process, make every set of customized doors and windows can meet the requirements of high-performance system doors and windows, which greatly enhances the core competitiveness of products.

Low utilization rate of environmental protection

Aluminum coated plastic doors and windows:

If the service life is not long, once installed, the recycling value is low, and main part material UPVC resin cannot be degraded, which causes great problems to environmental protection. If the black commercial waste PVC furnace is recast, the damage is N times larger than that of aluminum alloy waste. Once it enters the market, the situation is unimaginable.

PA laide doors and windows:

Aluminum coated plastic doors and windows:

If the service life is not long, once installed, the recycling value is low, and main part material UPVC resin cannot be degraded, which causes great problems to environmental protection. If the black commercial waste PVC furnace is recast, the damage is N times larger than that of aluminum alloy waste. Once it enters the market, the situation is unimaginable.

PA laide doors and windows:

It is not easy to age, even after several years, the recycling value of aluminum is still very high, which can be repeatedly refined and recycled. Even if it can be reused, pa laide is still made with the most original native aluminum ingot, which is far from the difference between strength and surface color.

Aluminum-coated plastic doors and windows are widely loved by consumers because of their excellent thermal insulation and energy saving performance. However, due to the short development time, there are still some shortcomings. Aluminum alloy doors and windows are still the mainstream in the door and window market. Aluminum alloy doors and windows have gone through 30 years from no one cares about them to becoming mainstream products in the door and window market. In these 30 years, a generation of doors and windows have been working hard at night, overcoming one technical problem after another, only then has the current market position of aluminum alloy doors and windows been achieved.

Similarly, PA laide doors and windows have experienced 24 years from scratch, from scratch to precision; Level 1 sun shade, Level 6 water tightness, Level 8 air tightness, Level 9 wind pressure resistance, each performance of the product has reached the highest level of national performance evaluation. In the future, pa laide doors and windows will require themselves with higher standards and strive to become a benchmark brand in the door and window industry!

The birth of various new concept materials

This shows that the door and window industry is developing vigorously.

While innovating and upgrading

The original intention, originality and perseverance should be maintained.

The market is the only standard for testing products.

There is a long way to go, and I will go up and down for help.

Let's wait and see!

Edit: doors and windows online-berries

It is not easy to age, even after several years, the recycling value of aluminum is still very high, which can be repeatedly refined and recycled. Even if it can be reused, pa laide is still made with the most original native aluminum ingot, which is far from the difference between strength and surface color.

Aluminum-coated plastic doors and windows are widely loved by consumers because of their excellent thermal insulation and energy saving performance. However, due to the short development time, there are still some shortcomings. Aluminum alloy doors and windows are still the mainstream in the door and window market. Aluminum alloy doors and windows have gone through 30 years from no one cares about them to becoming mainstream products in the door and window market. In these 30 years, a generation of doors and windows have been working hard at night, overcoming one technical problem after another, only then has the current market position of aluminum alloy doors and windows been achieved.

Similarly, PA laide doors and windows have experienced 24 years from scratch, from scratch to precision; Level 1 sun shade, Level 6 water tightness, Level 8 air tightness, Level 9 wind pressure resistance, each performance of the product has reached the highest level of national performance evaluation. In the future, pa laide doors and windows will require themselves with higher standards and strive to become a benchmark brand in the door and window industry!

The birth of various new concept materials

This shows that the door and window industry is developing vigorously.

While innovating and upgrading

The original intention, originality and perseverance should be maintained.

The market is the only standard for testing products.

There is a long way to go, and I will go up and down for help.

Let's wait and see!

Edit: doors and windows online-berries