1. Aluminum alloy cutting-off grinder is used for making cutting materials for doors and windows. Aluminum alloy profiles can be cut according to the required size and angle. The common cutting angle is 45 ° and 90 °. The cutting machine used in the production of large aluminum alloy doors and windows is large sawing machine. When cutting aluminum alloy profiles, the profiles can be smoothly placed on the workbench of sawing machine. The cutting length and angle are relatively accurate, and the kerf is neat, the cutting speed is fast; However, the cutting machine used in the processing point of small aluminum alloy doors and windows is small toothless saw, and the cutting precision is far less than that of large sawing machine.

2. Punch is used to punch holes on aluminum profiles, which can punch square, rectangular and round holes. Punch is the equipment used by large aluminum alloy doors and windows manufacturers, while small processing points are replaced by other equipment, and its precision and efficiency are far less than that of punch.

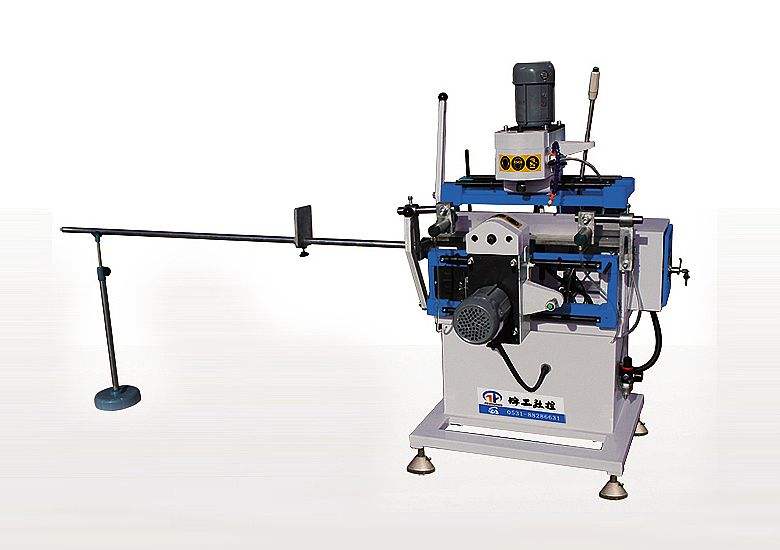

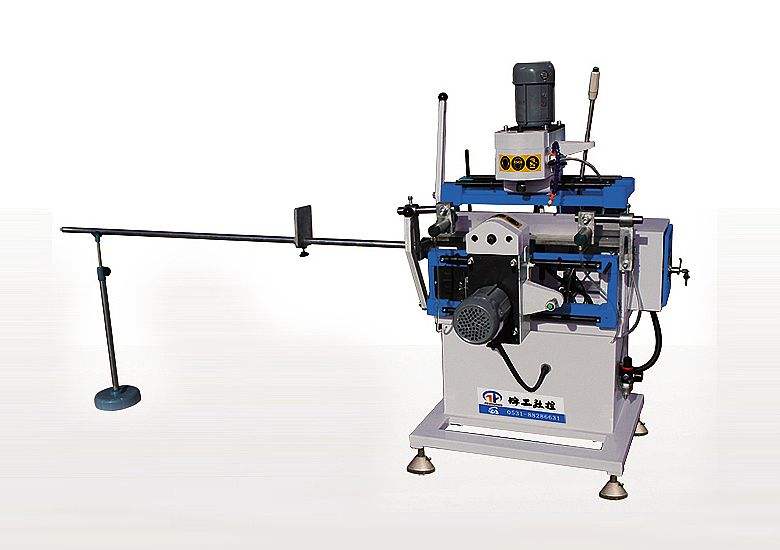

3. Profiling milling machine is mainly used for milling keyholes on profiles. Profiling milling machine can milling holes according to the shape of template, and the shape of template can be square, round, oval, eight-shaped, etc. It has the characteristics of intelligent hole milling, high precision and fast speed. The cost of imitation milling machine equipment is relatively high, and small processing points are generally not available. Hand Tapper is usually used instead.

4. Corner combining machine is mainly used for aluminum alloy door and window profile angle matching, which has the characteristics of high precision and beautiful angle matching. It is generally used by large aluminum alloy doors and windows factories, while small processing points are generally manual angle matching.