As a product of the 21st World New Era, system doors and windows are increasingly favored by consumers due to their durable and beautiful characteristics.

However, many people usually focus on door & window profile, hardware accessories, glass profiles and other issues when purchasing, and few people pay attention to the splicing process of corner sets.

Set ANGLE Technology, one of the most important indicators to evaluate the quality of doors and windows!

The corner assembly process is also called The Corner splicing process, which is the process used to splice two profiles.

The splicing part has always been a weak point. The Function of using set angle technology is to improve the angular strength of the door and window frame, and ensure that the door and window will not have corner slit when dealing with strong external forces such as violent impact and wind pull, problems such as connection deformation remain stable and durable.

(Image Source: ouzhe door and window contribution, invasion and deletion)

different processes achieve different levels of performance

at present, the common corner Group technology is mainly divided into three types: movable corner code technology, collision angle technology and pin glue injection technology, each of which has its own advantages and has different effects on the assembly mode and integrity of doors and windows, applicable to different scenarios and environments.

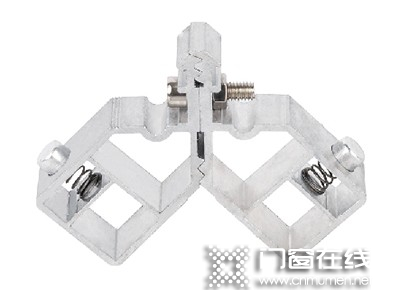

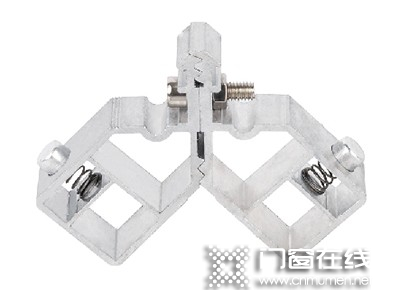

01. Activity angle code process

the movable angle code process is to fix the doors and windows by connecting the aluminum material through spring buckle, and then tightening it by screw. The left and right structures can be disassembled and installed at the construction site, which is convenient to enter the elevator to transport upstairs, it is a common connection method used in the door and window industry at present.

(Image Source: ouzhe door and window contribution, invasion and deletion)

however, the disadvantages of this process are also obvious. It can be quickly assembled on the site. It can be imagined that the connection is not tight enough and the sealing is general, which leads to easy water inflow, make the spring rust and lose elasticity or fracture, thus affecting the safety of the frame.

This kind of technology has tended to be eliminated in the middle and high-end doors and windows market, but due to the consideration of product cost and installation cost, such angle setting method still occupies a large market share in the low-end doors and windows.

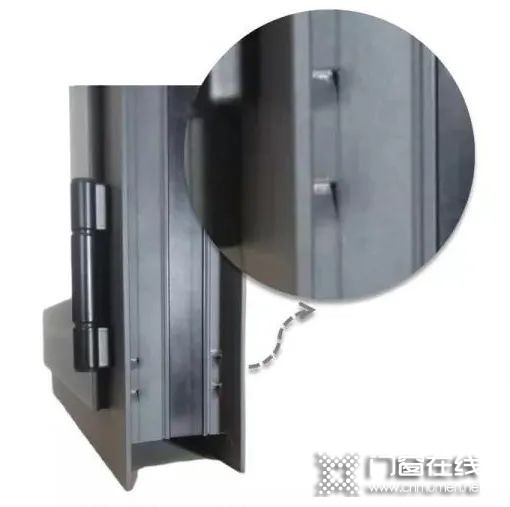

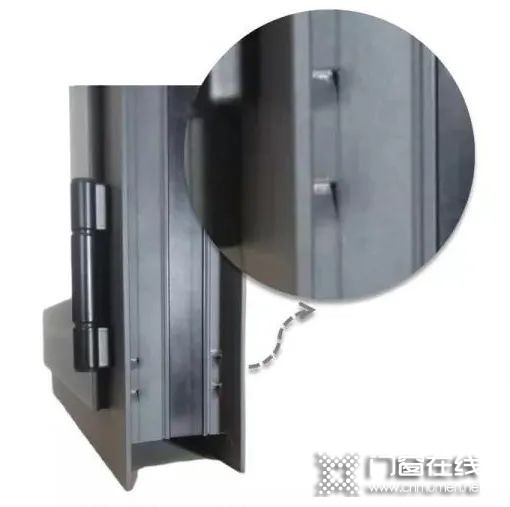

02. Angle collision process

the angle collision process is to put the surface of aluminum alloy profile on the section glue first, then insert the angle code into the 45 ° cut profile, and connect it through the impact and extrusion of precision machines. It is formed in one piece, which is seamless and not easy to crack.

(Image Source: ouzhe door and window contribution, invasion and deletion)

it is worth noting that due to the outstanding cost performance, this process has covered most of the system doors and windows market

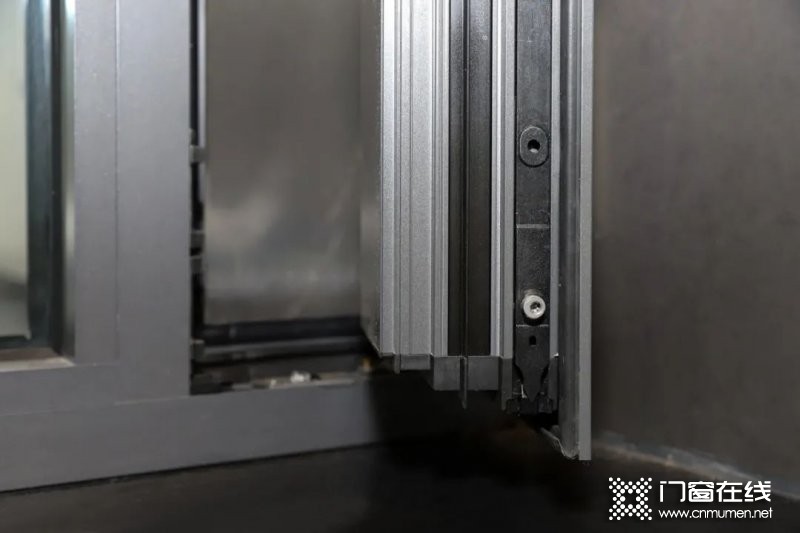

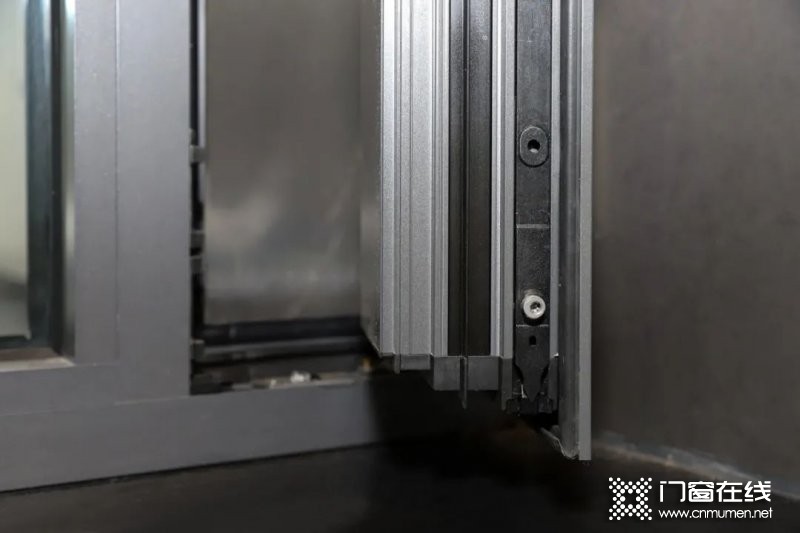

03. Pin glue injection process

the stability and sealing of pin glue injection process are the best among the three processes, and it is also the most excellent corner group process internationally recognized at present. Fasten the corner code through pins, and then inject glue into the interior to bond the gap between the corner code and the profile, thus realizing sealing and reinforcement.

(Image Source: ouzhe door and window contribution, invasion and deletion)

there are usually two kinds of angle codes used in this process. One is "popular style", which is formed by the combination of wire cutting aluminum corner brace plastic deflector. With the emergence of new angle codes, it gradually becomes popular basic style.

The other is the "advanced model", the thick wall structure with stronger integrity cast aluminum corner code, which has stronger rigidity and stability.

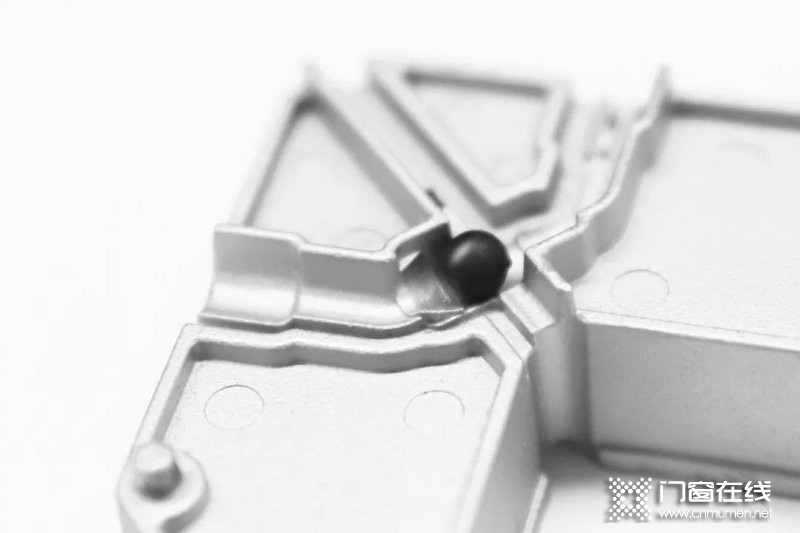

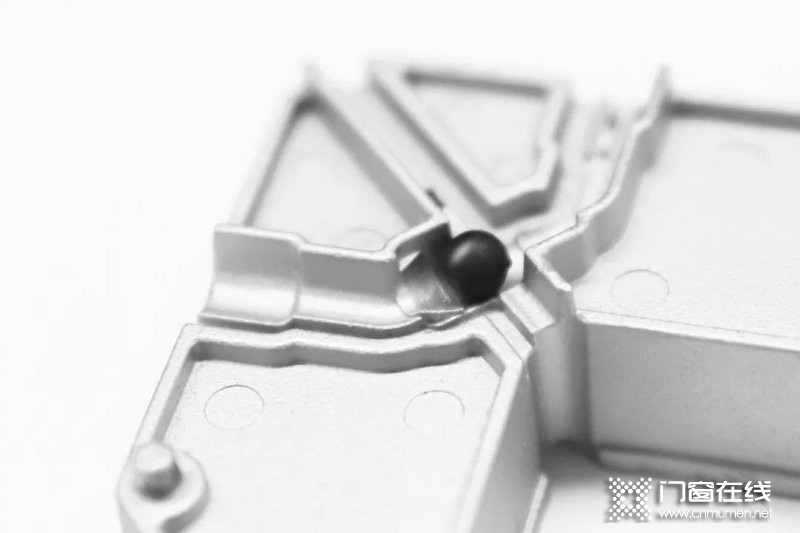

The angle code selected by Ou Zhe doors and windows is the "high fixed model" upgraded according to the "advanced model". A ball valve is added inside the cast aluminum angle code to adjust the flow of glue by using the ball valve principle, ensure that the glue can evenly fill all the gaps between the corner code and the inner wall of the profile to achieve seamless sealing.

(Image Source: ouzhe door and window contribution, invasion and deletion)

in addition, this angle code is also equipped with an upgraded version of the new hollow stainless steel pin, which can not only fasten the angle code, but also be used as a glue injection hole, which avoids the unaesthetic problem of opening another glue injection hole, it also has the function of tightening and smoothing corners.

(Image Source: ouzhe door and window contribution, invasion and deletion)

it is also because of the ultimate pursuit of OU Zhe doors and windows in angle setting technology, which ensures that the angle strength of doors and windows is extremely high, so the products of OU Zhe doors and windows can meet the "willful" large size, super large and super high design, not only does it not crack, even the super external force cannot be destroyed completely.

(Image Source: ouzhe door and window contribution, invasion and deletion)

ou Zhe's doors and windows hope that the system doors and windows adhering to the concept of "making home safer" can satisfy the yearning of high-end elites for comfortable living and lead the ideal lifestyle.