Double layer hollow glass application:

Double layer hollow glass application:

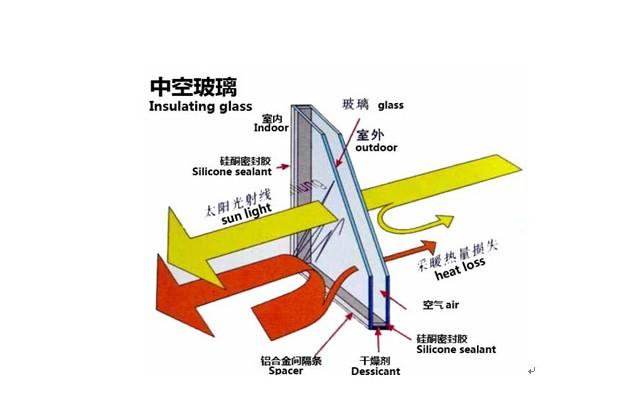

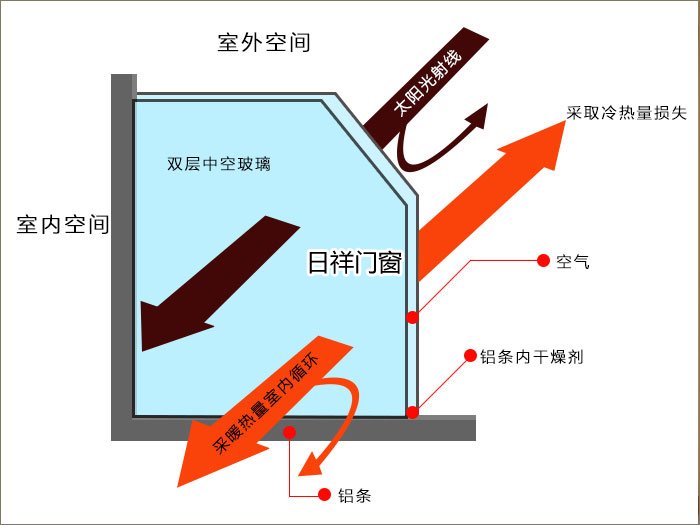

hollow glass was invented by Americans in the 19th century. Hollow glass seals air between two layers of glass through sealing processing, thus playing the roles of heat insulation, heat preservation and defrosting. By the beginning of the 21th century, hollow glass had just entered the homes of our Chinese people, and now it has become plastic steel doors and windows and

broken bridge aluminum doors and windows standard glass configuration.

Common hollow glass include ordinary hollow glass, vacuum glass and special hollow glass filled with inert gas in the middle,

we ordinary people use ordinary hollow glass at home, that is, glass sealed with air in the middle.

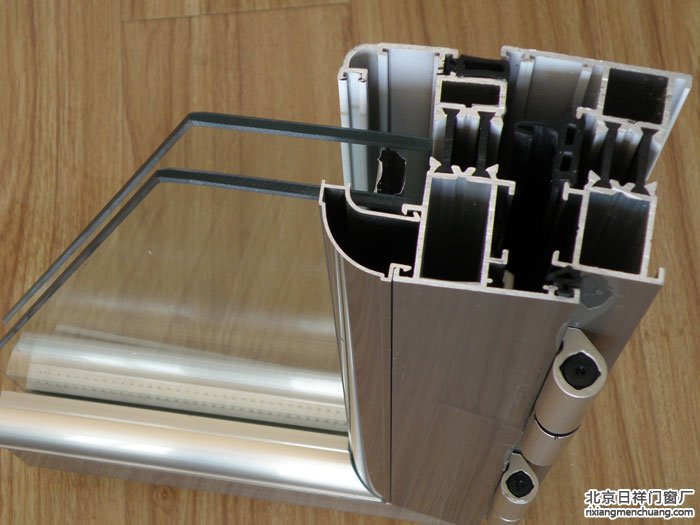

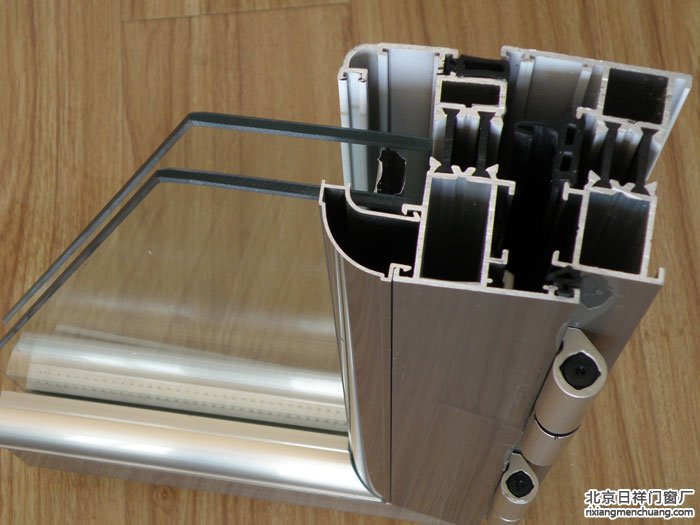

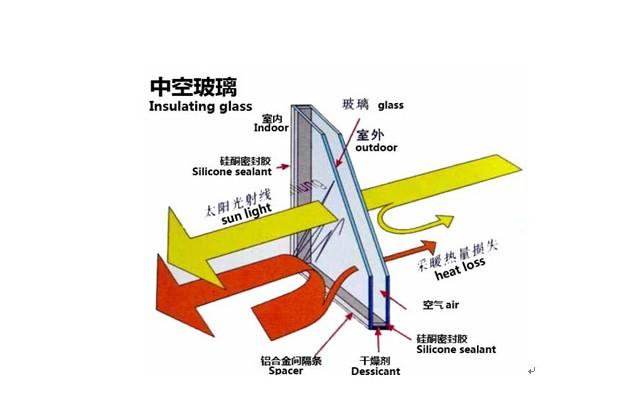

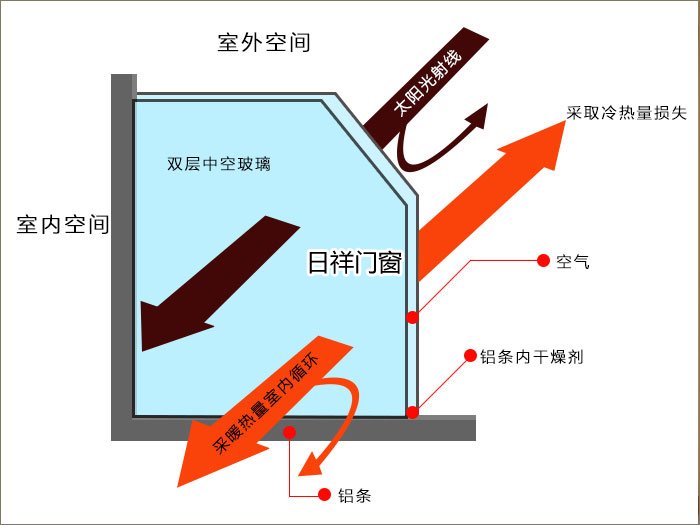

Structural Analysis of double glazing unit:

two layers of glass, separated by aluminum spacing strip in the middle, filled with desiccant in the middle of aluminum spacing strip, and sealed with tinned silicone sealant for two times around. So as to ensure that the air layer in the hollow glass is kept dry for a long time, without water and dust.

Parameter description of double glazing unit:

Parameter description of double glazing unit:

examples of common insulating glass parameters, such as 5 9A 5 double-layer hollow. Here, 5 means that the thickness of glass is 5cm, 9 means that cavity is 9mm, and the letter A is the abbreviation of English air.

There are other models on the market, such as 5 15A 5,5 22A 5,5 27A 5,5 32A 5, etc. It is not difficult to understand the above meaning. They are all 5mm two-layer glass with different spacing between them. The larger the interval, the better the sound insulation effect.

Regular size

Regular size hollow glass:

5 6A 5, 5 9A 5, 5 12A 5, 5 15A 5, 5 18A 5, 5 22A 5, 5 24A 5, 5 27A 5, 5 32A 5 , 6 9A 6 ,6 12A 6

FAQ:

1. Why is there water in the middle of the glass?

A: The glass seal is not good, and the air leaks. Hollow glass is also sealed air inside. If the sealant quality is not good or the sealing process of the processing plant is not good, hollow glass windows will be exposed to the sun after being used for a period of time, water gas and other reasons lead to the aging failure of sealant and air leakage. When air leakage occurs, water will be injected.