What is glass fiber reinforced polyurethane energy-saving doors and windows? "Glass Fiber Reinforced Polyurethane energy-saving doors and windows" is an industry standard implemented on December 1, 2019.

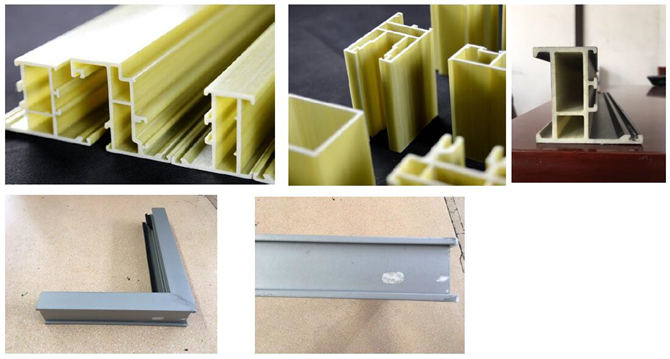

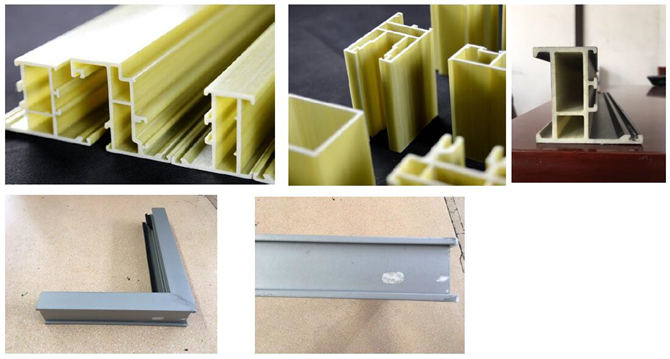

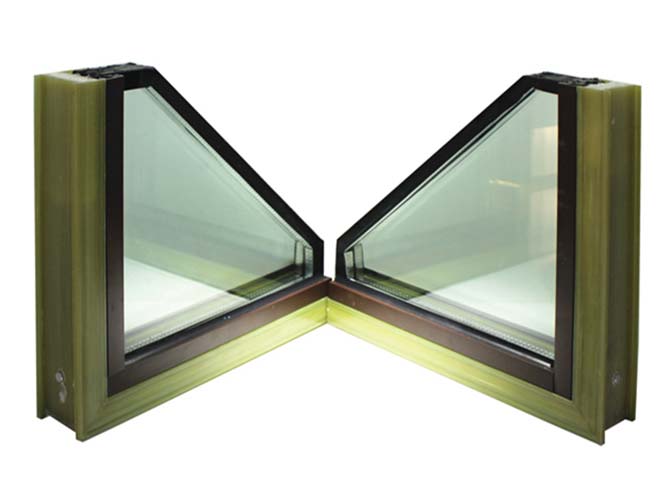

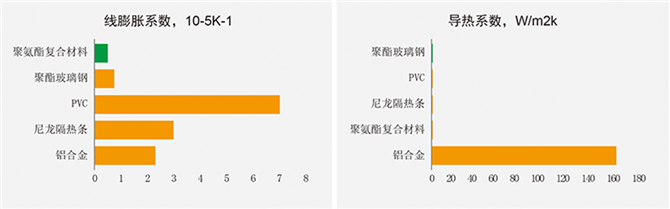

Glass Fiber Reinforced Polyurethane, namely Glass Fiber Reinforced Polyurethane (abbreviated as GRPU), is a high-performance composite material, which uses non-woven Glass Fiber yarn as reinforcing material and Polyurethane resin as matrix resin, it is generated by injection dipping pultrusion process. Due to its fiber reinforcement, its compressive strength, tensile strength and bending strength are very high. With the country's higher and higher requirements for building energy conservation, this material has unique sound insulation, heat preservation, fire resistance, aging resistance, linear expansion coeffcient low, energy saving and environmental protection, etc., has been used in the field of energy saving doors and windows.

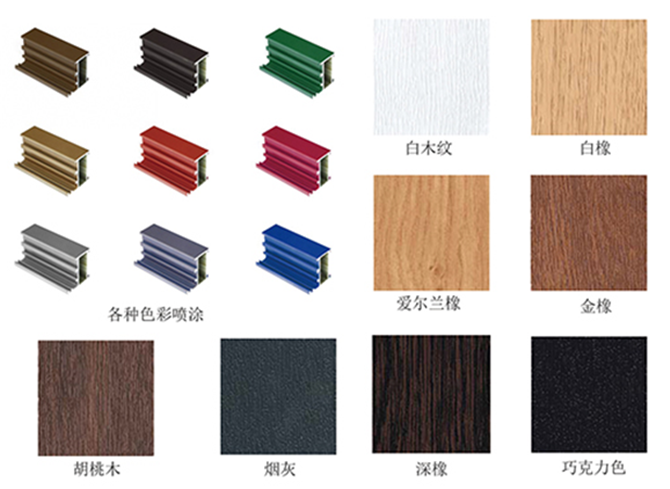

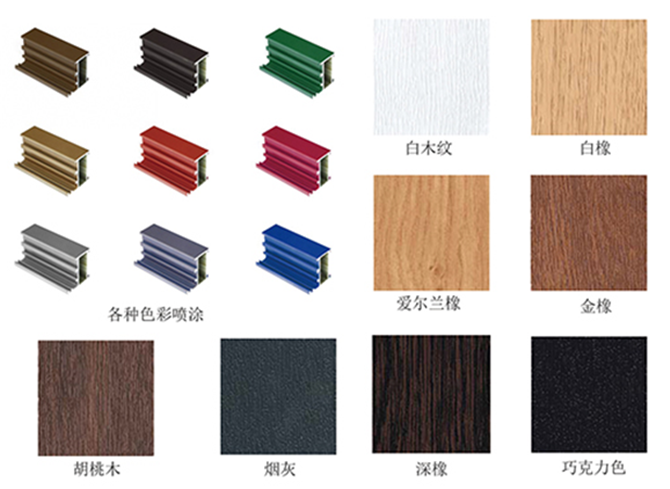

In the application of doors and windows, glass fiber reinforced polyurethane profile has obvious advantages compared with bridge-cutoff aluminum alloy and plastic steel. The doors and windows made have obvious advantages in heat preservation, wind pressure resistance, air tightness, water tightness, sound insulation, fire prevention, corrosion resistance and other properties have advantages. At the same time, the surface of the profile can be painted with various coating treatments, and the effect is rich.

Glass fiber reinforced polyurethane energy-saving doors and windows product performance:

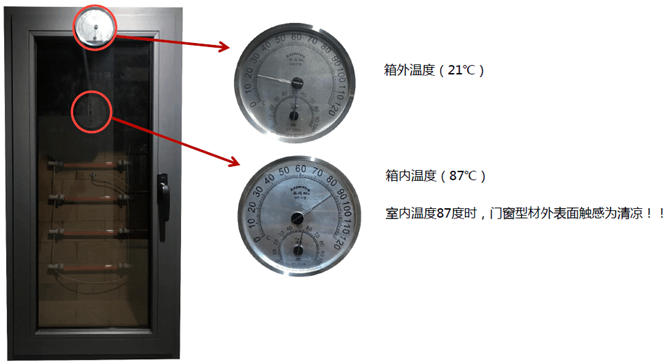

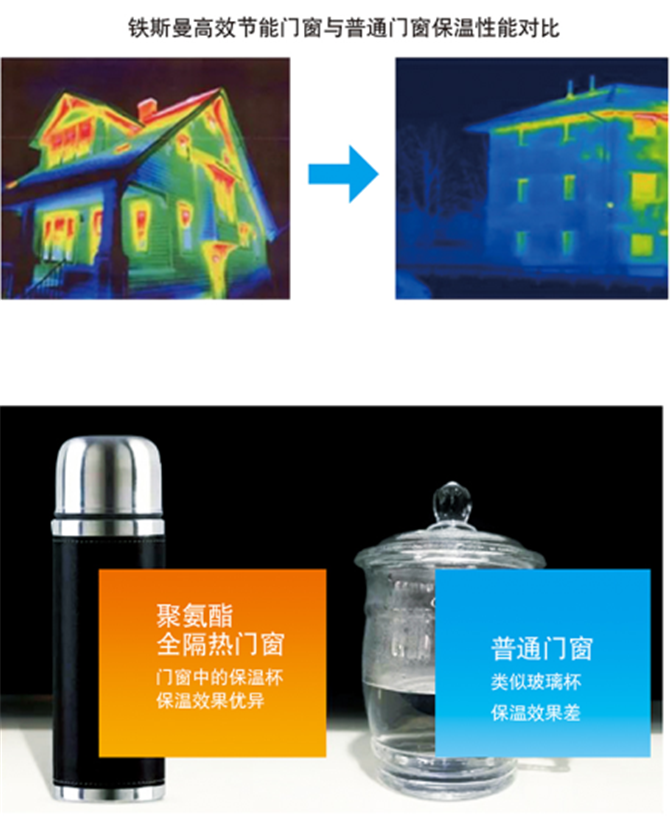

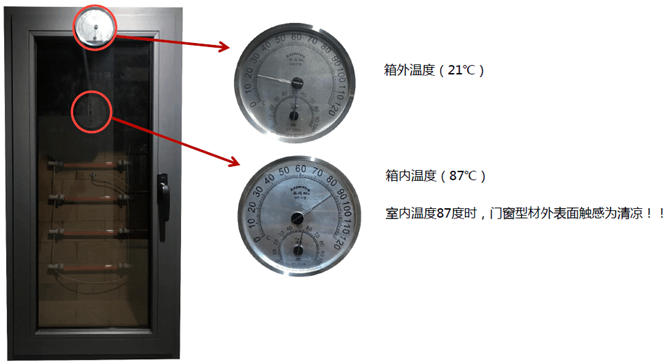

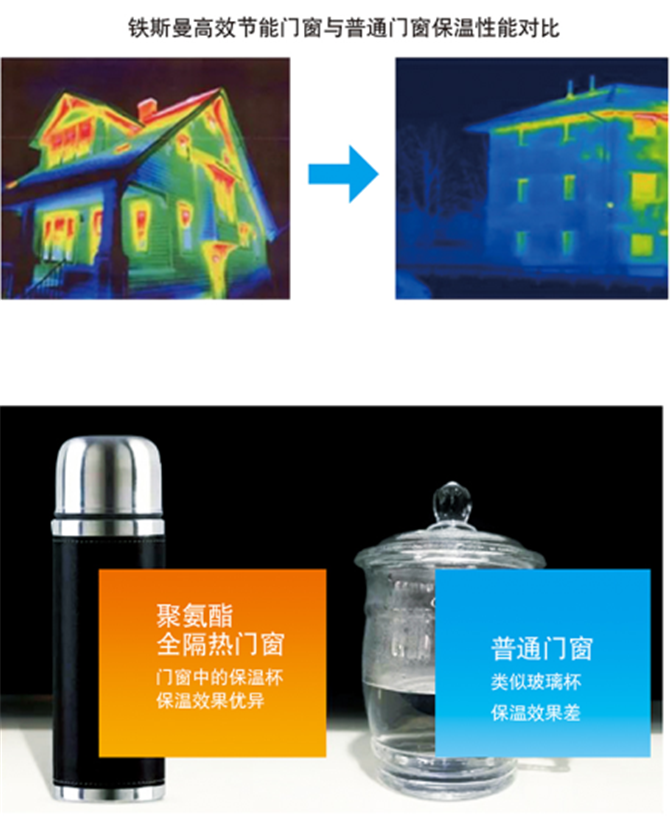

1. Glass fiber reinforced polyurethane energy saving doors and windows super energy saving.

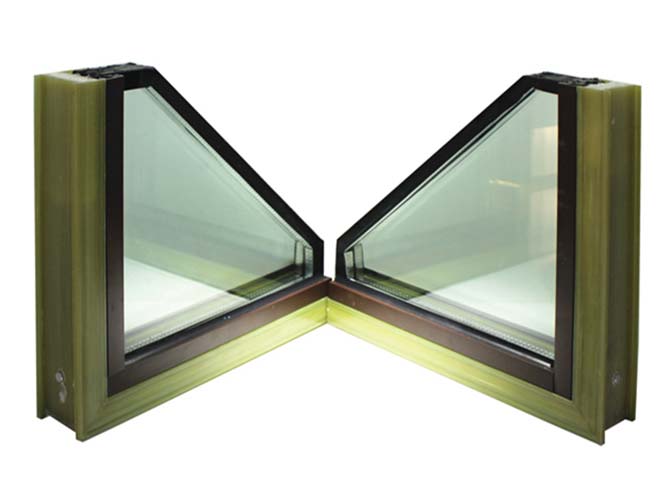

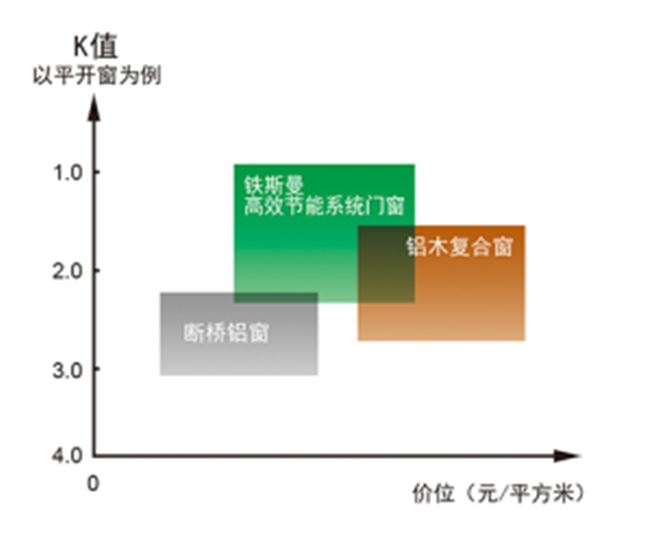

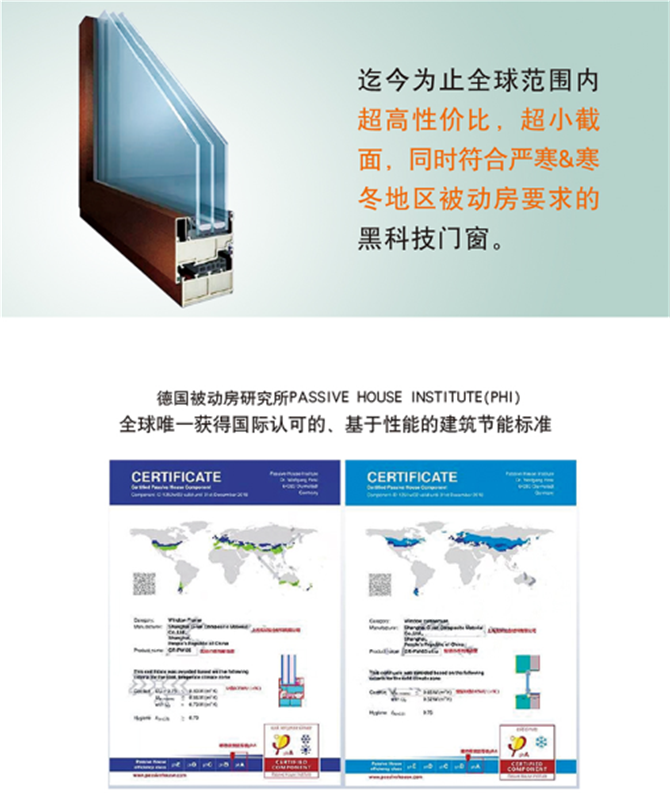

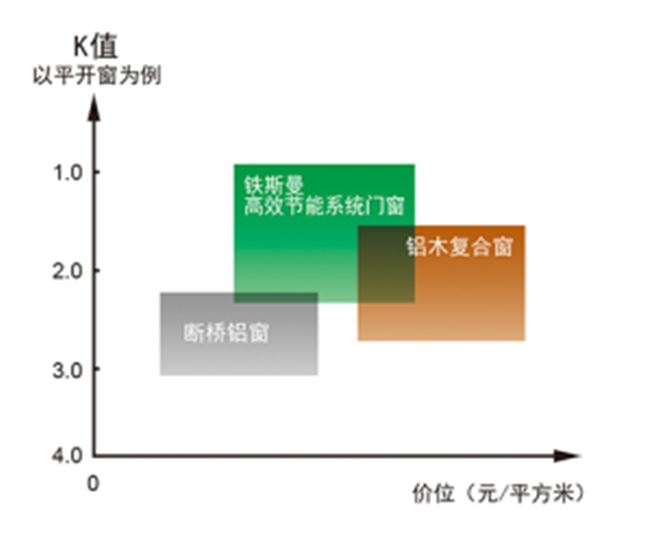

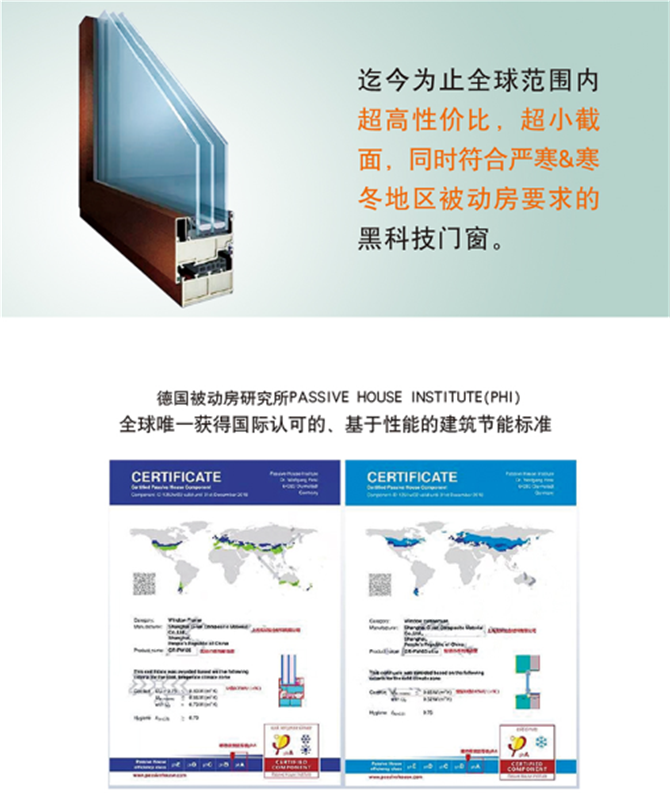

The system does not need to break bridges and steel lining, and its profile has superior thermal conductivity: when the whole window design K = 2.0, the energy-saving performance of the two-layer glass of the system surpasses that of aluminum alloy by Triplex glass. With three glasses, it can reach the standard of Passive House K = 0.9 * W/㎡ · K, and the visible surface is only 210px, which is the choice of passive house door and window system with extremely high cost performance. Moreover, the profile has reliable low temperature resistance. Through the physical performance comparison test of-40C freezing and thawing hundreds of times, the mechanical properties are guaranteed in extremely low temperature environment.

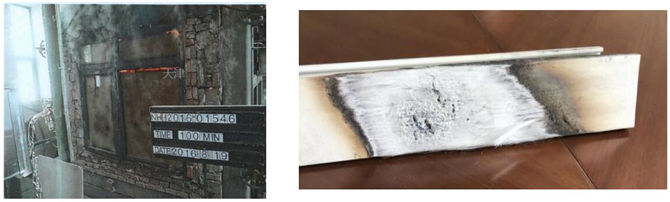

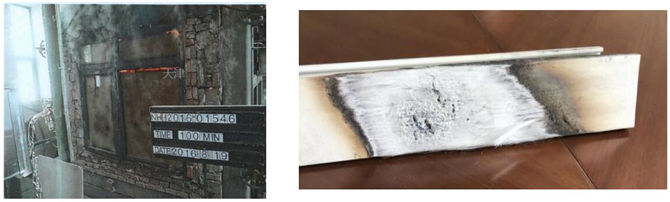

2. Glass fiber reinforced polyurethane energy-saving doors and windows have good fire resistance.

Glass fiber reinforced polyurethane profile fire resistance comes from the material itself. Glass fiber is an inorganic fiber with good flame retardant and heat resistance, and its melting point is usually above 1000 degrees. However, polyurethane material is a thermosetting material, which will form a carbonized layer on the surface after fire, preventing the flame from going deep, not melting and not producing dissolved droplets. Glass fiber reinforced polyurethane composite material is difficult to burn when exposed to fire, and the high temperature of exposed surface is difficult to conduct to the other side.

According to various fireproof glass configurations, the fire integrity can be achieved for 0.5-1.5 hours!

3. Super sound insulation.

The sealing performance of this system is good, and the air tightness of sliding window can reach 6 levels; The wind pressure resistance can reach 8 levels; Super sound insulation, especially suitable for houses in high noise areas such as elevated roads, flight channels, and downtown roads, sound insulation performance ≥ 42dB.

4. Ultra-high air tightness and good water tightness

The ultra-high air tightness can be beneficial to heat preservation, heat insulation and sound insulation. The doors and windows of the high-efficiency energy-saving system of Tiesman meet the highest 8-level national standards. The water retaining platform with high design of system doors and windows adopts three seals in-swinging casement window, the watertightness of the whole window can reach level 4.

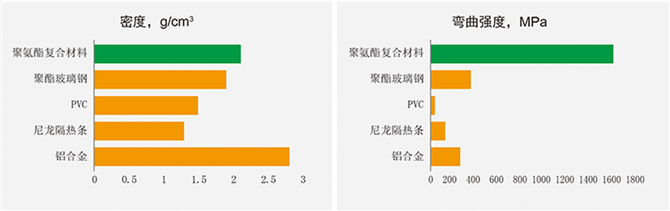

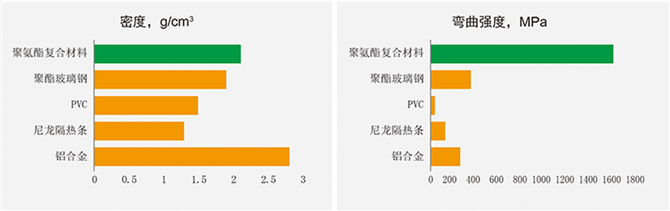

5. Light weight, high bending strength, top wind pressure resistance, larger frame fan size can be designed, and long service life.

The density of this profile is small, 25% lighter than that of aluminum alloy, and the bending strength is 5 times that of aluminum alloy. The ultra-high strength makes the profile section 10% smaller than that of aluminum alloy, greatly improving the permeability of home vision. Continuous fiber greatly improves the strength, hardness and elastic modulus by polyurethane profile (bending modulus can reach 51GPa), and stable hollow glass bearing can be realized without lining reinforced steel.

The wind pressure resistance of doors and windows of the high-efficiency energy-saving system can reach the highest national level 9 standard (5000PA), and there is no need to increase the reinforcement of the whole steel frame. Because this profile has greater strength performance than aluminum alloy, fixed and Open fans with a size greater than broken bridge aluminum doors and windows can be made, which can be used in high-rise and high-altitude buildings.

Compared with thermoplastic materials such as polyamide and polyvinyl chloride, glass fiber reinforced polyurethane pultruded sections has superior aging resistance and corrosion resistance, so it has a longer service life (up to more than 50 years).

6. Corrosion resistance and salt spray resistance, good decorative effect and long service life.

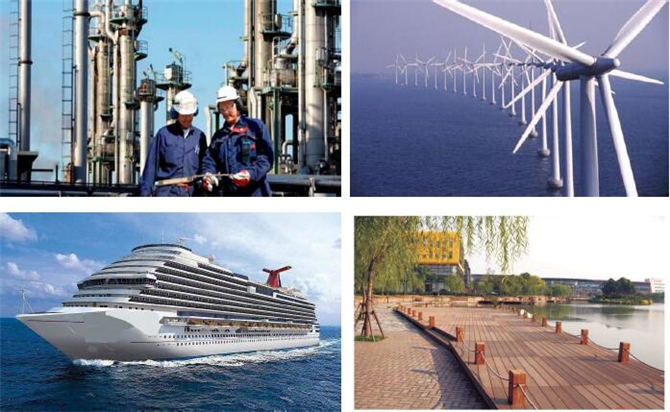

The profile of this system is a polymer composite material. In addition to the rich color like aluminum alloy, the weather resistance of the special process coating on the surface is about 1.5 times that of the aluminum alloy powder spraying process. The coating is corrosion resistant, it is especially suitable for use in coastal areas with high seawater corrosivity, and is suitable for coastal building doors and windows, seaside slope protection embankment Engineering, replacing regular wetland antiseptic Wood, Marine Ship Engineering, petrochemical engineering, wind power generation blades, etc.

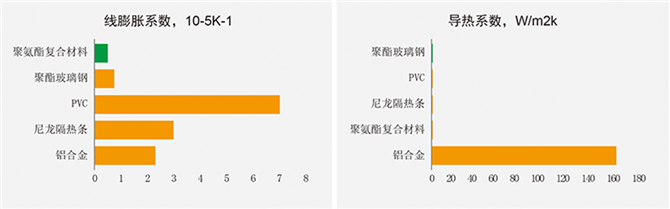

7. Linear expansion coeffcient small, suitable for Assembly building

The size shrinkage rate of this profile is less than or equal to 0.2% , and the linear expansion coeffcient is 0.5~0.8( 10-5K-1). It is close to concrete and has high stability. It is very suitable for assembled buildings.

8. Broad market prospects

The annual demand for domestic doors and windows is about 0.37 billion m2. With the improvement of national requirements for building energy conservation, polyurethane composite doors and windows are expected to account for 20% of the door and window market, and the demand for polyurethane pultruded sections will reach 10,000 tons, it has a very large demand market for raw materials.

Compared with other door & window profile:

Product Application:

The strength of glass fiber reinforced polyurethane material is much higher than that of aluminum alloy, with low thermal conductivity, good fire resistance, strong thermal insulation and relatively low price. Compared with traditional materials, it can achieve the best performance of doors and windows with smaller cross section and simpler structure, greatly reduce the cost of the original passive room doors and windows, and is an excellent choice for fire-resistant windows and passive windows. 85 series passive windows have passed PHI certification. PHI German Passive Energy Conservation Research Institute is the only internationally recognized performance-based building energy conservation standard.

The lightweight and high-strength properties of glass fiber reinforced polyurethane material make the profile excellent in air tightness, water tightness, wind pressure resistance and sound insulation, and can be made into super large area high vision doors and windows. The superior performance determines its dominant position in the field of doors and windows. The doors and windows made of them have advantages in various properties such as heat preservation, wind pressure resistance, air tightness, water tightness, sound insulation, fire prevention, corrosion resistance, etc. At present, this new material has been widely used in doors and windows of large public buildings and home decoration industries, with broad market prospects.