Silicone sealant is a paste made of polydimethylsiloxane as the main raw material, supplemented by crosslinking agent, filler, plasticizer, coupling agent and catalyst in vacuum state, elastic silicone rubber is formed by curing with woter in the air at room temperature.

1 silicone silicon sealant classification

Silicone silicon sealant can be divided into two types from product packaging: one-component and two-component. One-component silicone adhesive, its curing is due to contact with moisture in the air to produce changes in physical properties; Two-component refers to silicone adhesive divided into two groups A and B, any group alone cannot form curing, but once the two groups of adhesive cement are mixed, curing occurs. At present, one-component silicone silicon sealant is common in the market. This book mainly introduces this kind of silicon sealant.

One-component silicone silicon sealant can be divided into acid glue and neutral glue according to their properties. Acid silicon sealant is mainly used for general bonding between glass and other building materials. However, neutral glue overcomes the characteristics that acid glue corrodes metal materials and reacts with alkaline materials, so it has a wider application range and its market price is slightly higher than that of acid glue. A special type of silicon sealant on the market is structural silicone sealant. Because it is directly used for metal and glass structure or non-structural adhesive assembly of glass curtain wall, the quality requirements and product grade are the highest in silicon sealant, its market price is also the highest.

2 Brief introduction of silicone silicon sealant

One-component silicone silicon sealant is similar to Ointment. Once exposed to moisture in the air, it will solidify into a tough rubber solid material. Silicone silicon sealant has strong adhesion, high tensile strength, weather resistance, vibration resistance, moisture resistance, odor resistance and great adaptation to hot and cold changes. In addition, its wide applicability can realize the bonding between most building materials, so its application value is very large. Silicone silicon sealant does not flow due to its own weight, so it can be used for joints over the top or side walls without subsidence, collapse or flow away. It is mainly used for the bonding of dry and clean metal and glass, most grease-free wood, silicone resin, sulfur-added silicone rubber, ceramics, natural and synthetic fibers, and many paint plastic surfaces. Silicone silicon sealant with good quality will not be extruded or changed in physical properties when used below zero degrees Celsius. Fully cured silicone silicon sealant can still remain effective when used at a temperature of 204 ℃(400oF), but when the temperature is as high as 218 ℃(428oF), the effective time will be shortened. Silicone silicon sealant has many colors, including black, porcelain white, transparent, silver gray, gray and bronze. Other colors can be customized according to customer requirements.

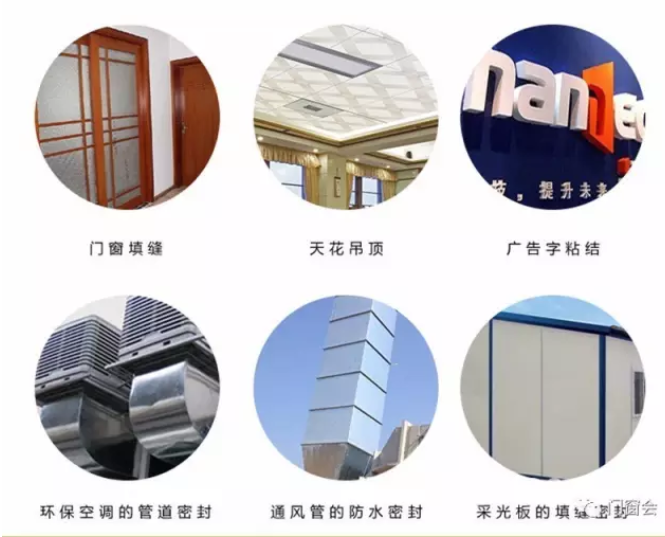

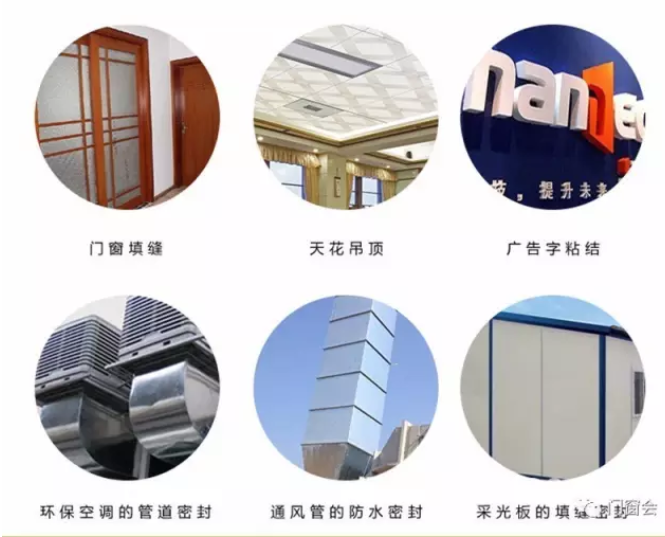

3 silicone silicon sealant use

(I) acid silicon sealant

1. It is suitable for sealing, blocking, leak-proof and weatherproof purposes. Both indoor and outdoor are suitable (indoor effect is better), and the anti-seepage and leak-proof effect is remarkable.

2. Bonding various interior decorations of automobiles, including metal, fabric, woven fabric and plastic.

3. Join the gasket on the heating and refrigeration equipment.

4. Add fillet without screw holes, nameplate, paint and plastic materials on the metal surface. 5. Seal the window on the oven door, flue, pipe joint and access door on the gas appliance.

6. Provide instant forming leak-proof pad for gear box, compressor and pump.

7. Seal the cabin and window.

8. Seal the glass window of trailer and truck cab.

9. Bonding and sealing equipment parts.

10. Form anti-wear coating.

11. Inlay and fill thin metal sheet layers, pipe network and equipment chassis.

(Ii) neutral weather proofing sealant

1. It is suitable for weather-resistant sealing of various curtain walls, especially recommend for weather-resistant sealing of glass curtain walls, aluminum-plastic plate curtain wall and stone dry hanging;

2. Joint sealing between metal, glass, aluminum, ceramic tile, organic glass and coated glass;

3. Joint sealing of concrete, cement, masonry, rock, marble, steel, wood, anodized aluminum and painted aluminum surfaces. In most cases, primer is not required.

(Iii) silicone structural adhesive

1. It is mainly used for metal and glass structure or non-structural bonding assembly of glass curtain wall.

2. It can directly connect the glass with the surface of the metal component to form a single assembly component, meeting the design requirements of curtain wall with full hidden or semi-hidden frame.

3. Structural bonding and sealing of hollow glass.

4

All kinds of silicone silicon sealant will be subject to the following restrictions when used

1. It is not suitable for construction where the water is immersed for a long time;

2. Materials that do not exude grease, plasticizer or solvent will dissolve together;

3. Frost or wet surfaces cannot be bonded;

4. The completely sealed place cannot be cured (silica gel needs * Moisture curing in the air);

5. The surface of the substrate is not clean or firm.

(1) acid silicon sealant has the following restrictions:

Acidic silicone silicon sealant will corrode or cannot bond copper, brass (and other copper-containing alloys), magnesium, zinc, electroplated metals (and other zinc-containing alloys), at the same time, it is recommended not to use acidic silicon sealant on brick and stone products and iron carbide matrix, and to use methyl methacrylate (PLEXIGLAS), polycarbonic acid, polypropylene, polyethylene and TEFLON (TEFLON, Polytetrafluoroethylene) the use of this product on the made materials will not achieve good bonding effect and good compatibility. It is not suitable to move connections that are greater than 25% of the joint width to use acidic silicon sealant. It is better not to use ordinary acidic silicon sealant (except acidic structural adhesive) on structural glass, in addition, acid silicon sealant should not be used where abrasion and substantial drawbacks occur. It is not suitable for construction when the surface temperature of the base material of silicone acid glue exceeds 40℃.

(2) neutral weather proofing sealant has the following restrictions:

Neutral weather proofing sealant is not suitable for structural glass Assembly; It is not suitable for construction when the surface temperature of the substrate exceeds 50℃.

(Iii) silicone structural adhesive has the following restrictions:

The surface temperature of the base material of silicone structural adhesive exceeds 40℃, which is not suitable for construction.

5 silicone silicon sealant usage

1. Use: one-component silicone silicon sealant can be used immediately. It is easy to punch it out from the plastic bottle with gluing gun, and the surface can be trimmed with scraper or wood piece.

2. Sticking Time: silicone adhesive of the curing process develops inward from the surface, the surface drying time and curing time of silica gel with different characteristics are different (for more information about curing time, see technical parameters in chapter 4), therefore, if you want to repair the surface, it must be carried out before the surface is dried at silicon sealant (acid glue, neutral transparent tape should generally be within 5-10 minutes, and neutral variegated glue should generally be within 30 minutes). If textured paper is used to cover a certain place, after gluing, it must be taken away before the skin is formed.

3. Curing time: the curing time of silicon sealant increases with the increase of bonding thickness. For example, the acidic silicon sealant with a thickness of 12mm may take 3-4 days to solidify, but within about 24 hours, the outer layer of 3mm has been cured. When bonding glass, metal or most wood, it has a peeling strength of 20 pounds per inch after 72 hours at room temperature. If silicon sealant of the places are partially or completely closed, the curing time is determined by the tightness of the seal. In an absolutely closed place, it is possible to remain uncured forever. If the temperature increases, silicon sealant will become soft. The gap between metal and metal bonding surface should not exceed 25mm. In various bonding occasions, including sealed conditions, the bonding effect should be comprehensively checked before using the bonded equipment. Acid silicon sealant in the curing process, the volatilization of acetic acid will produce a smell, which will disappear during the curing process, and there will be no odor after curing.

4. Bonding:

A. Wipe the metal and plastic surfaces completely and remove oil stains. Then, in addition to rinsing all the surfaces with acetone for plastic, apply rubber covering sand-papering and then wipe them with acetone. Please observe the precautions when using acetone.

B. Apply silicon sealant evenly on the surface of the ready object. If the two surfaces are bonded, put one side first to find the position, and then squeeze the other side with enough force to squeeze out the air, however, be careful not to squeeze out silicon sealant.

C. Place the bonding device at room temperature and wait for silicon sealant curing.

5. Sealing: When silicone silicon sealant is used for sealing, it is also carried out according to the above steps. Squeeze the silicon sealant into the joint surface or gap to make the silicon sealant fully contact with the surface.

6. Cleaning: silicon sealant can be wiped off with cloth strips or paper towels before curing. After curing, it must be scraped off with a scraper or scrubbed with solvents such as xylene and acetone.

7. Precautions: acid silicon sealant releases irritant gas during curing, which can irritate human eyes and respiratory tract. The alcohol gel releases methanol during the curing process. Methanol is potentially carcinogenic and is a known allergy to skin and respiratory tract. Volatile gases can irritate eyes, nose and throat. Therefore, this product should be used in a well-ventilated environment to avoid entering eyes or contact with skin for a long time (after use, wash hands before eating or smoking), and should not swallow this product. Do not allow children to contact; The construction site should be well ventilated; If accidentally splashed into eyes, rinse with clean water and seek medical treatment immediately. Silicon sealant after complete curing is not dangerous.

8. General Guide: before using, please read the correct construction methods and uses of silicon sealant carefully. Please pay attention to the instructions on safe use and health hazards.

6 silicone silicon sealant storage

Storage and storage period silicon sealant should be stored in a cool and dry place, below 30℃. Good quality acid silicon sealant can ensure the effective storage period of more than 12 months, generally acid silicon sealant can be stored for more than 6 months; Neutral weather resistance and structural adhesive can guarantee the shelf life of more than 9 months. If the bottle has been opened, please use it in a short period of time; Silicon sealant if it is not used up, the plastic bottle must be sealed. When using it again, screw down the bottle mouth, remove all bulkhead or replace the bottle mouth.