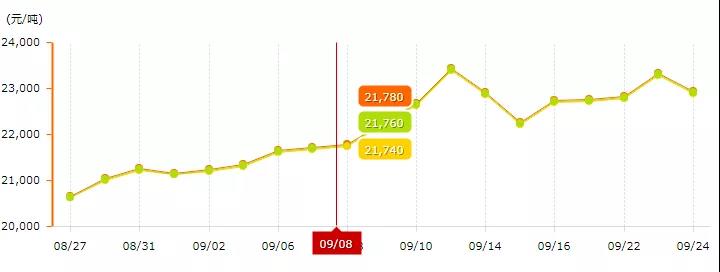

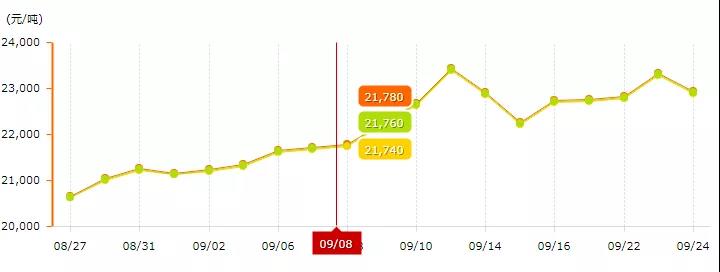

Recently, the price of aluminum continued to soar. The price of aluminum on the London Metal Exchange (LME) once touched US $3,000 per ton, the highest level since July 2008, the main price of Shanghai aluminum in Shanghai Stock Exchange reached 23895 yuan per ton, the highest level in nearly 15 years.

Since August, news of the impact of limited electricity and dual control of energy consumption on the upstream aluminum electrolysis industry has been constantly emerging, and major producing areas such as Xinjiang, Guangxi, Guizhou, Inner Mongolia and Yunnan have been affected, in addition, the recent overseas events in Guinea have caused hidden worries about ore supply, and aluminum prices at home and abroad continue to rise. At the same time, benefiting from the favorable pull of carbon neutrality, the aluminum industry chain has also risen. It is expected that for a long time to come, the demand and market conditions of aluminum will continue to be good, and the price is expected to reach a new high.

Aluminum prices hit a 15-year high, downstream aluminum Gross profit decreased by 25%, on the verge of shutdown

It is reported that the price of aluminum has risen 117 percent since last year's 11000 yuan/ton. When the aluminum industry made a lot of money, the downstream industry complained bitterly. An aluminum profile company said that its products are mainly priced and sold through aluminum ingot price plus processing fees. Recently, the price has risen aluminum ingot, and processing fees have also increased by about 500-600 yuan/ton. At present, there is almost no profit, however, for the normal operation of the factory and the maintenance of the customer group, we can only continue to receive orders. At present, orders of most aluminum profile enterprises have been reduced by about 30%, and production lines have also stopped production.

Some other door and window sellers said that the gross profit margin of aluminum alloy doors and windows in the past was still 30%, but now it has dropped to about 5%, plus the initial fixed asset investment and other financial expenses, etc, there is almost no profit for new orders. If it is responsibility contract signed before the aluminum price rises, it is doomed to lose money.

According to the understanding of the paint purchasing network, this situation is not a case. In the first half of the year, bulk chemical products continued to rise, and the price even hit new highs repeatedly. However, this degree of prosperity did not pass on, but gradually decreased. Under this year's "prosperity paradox", the upstream is in full swing and the downstream is as cold as ice. Aluminum industry, household appliances, automobiles, furniture and other industries are all "locked" in the trap of high raw material prices, losses of tens of millions, order reduction, partial shutdown and near bankruptcy are everywhere.

Chips soared 10 times, and 3 million cars worldwide stopped production.

In the first half of 2021, there was a round of "core shortage crisis" around the world. The supply cycle of chips was extended from 3 months to 12 months, and the unit price of some chips had risen from 10 yuan to 100 yuan, the price has risen more than 10 times, and currently 3 million cars worldwide are stopped.

As of September 5, the number of cars in the world has been reduced by 7.327 million. At the same time, market agencies also predict that the global car will be reduced by 8.107 million in 2021. It is worth mentioning that the executives of automobile manufacturers such as Ford, Volkswagen and Daimler all expressed concern about the chip shortage and believed that it was difficult to see the improvement in the short term.

Timber rose 188%,50% furniture factory stopped production and closed

Since the Spring Festival, the price of wood floor raw materials has increased by two rounds. The price of wood base material, facial tissue, wear-resistant paper and so on has increased by more than 25%, and the price of composite floor has increased by about 1-2 yuan per square meter, pure solid wood increased by 20-50 yuan/㎡, while labor and transportation costs also increased by 8%-10%. In addition, the severe overseas epidemic has led to an increase in the cost of imported timber in our country. The original timber of 2,000 yuan/cubic meter has now risen to 3,000 yuan/cubic meter in addition to transportation and labor costs, the price has risen 15% from the beginning of the year. Since the outbreak of the new Crown outbreak, the global timber price has increased by 188%, so that the industry calls this phenomenon "timber crisis".

As the pressure on the cost side increases, downstream furniture factories soon fall into a difficult dilemma. The cost of raw materials increases, and the cost of labor and marketing also increases, this is undoubtedly worse for the furniture industry that has entered the "low profit era. An Enterprise said that shipping freight was too expensive and orders were suspended, which also reduced its furniture trade and other shipments by 40%. At present, at least 50% of small and medium-sized solid wood furniture factories have stopped production or closed down, and the furniture industry is facing a "desperate contest" between profit and raw material price increase ".

The cost has increased by 30%, and household appliance enterprises have suffered heavy losses.

Since this year, commodity prices have continued to rise and remain relatively high. Among the raw materials of household appliances, the aluminum, Rebar (active) and plastic indexes of LME3 months increased by 27.34%, 27.42% and 6.73% respectively, and the copper of LME3 months reported at the beginning of the year at 7856 USD/ton, at present, it has risen to 9535 USD/ton, up%.

Plastic, compressor, and packaging materials like Carton and foam are all rising prices. The main raw material of the compressor is steel, so the price rises, the increase is between 8% and 10%, and the cost of refrigerators and freezers rises by about 25%, the price of all kinds of raw materials of electric fans has increased by nearly 50%, pushing up the cost of the whole machine by 30%.

Some household appliance enterprises said that the rising price of raw materials has caused huge operating pressure on the enterprises. At present, they have lost 3 to 40 million yuan, and they cannot see the hope of reversing in the next few months. Because I dare not increase the price rashly, I am worried that it will affect the sales volume. After the order is reduced, in order not to allow the capacity to be idle too much, even if it is a loss, it should be hard to cut down the loss order.

Profits are upside down, and more than 300000 downstream enterprises have closed down.

In addition, the prices of various raw materials such as chemical industry, plastics, steel, coal, cement, building materials and so on have been rising. Iron ore has reached a record. Steel has surpassed the highest point since 2008, and copper prices have risen to a new 16-year high, coal has reached a record high, and many varieties of titanium dioxide and resin in the chemical industry have refreshed the historical high value...... Costs and profits are upside down in multiple industries.

The upstream purchase of materials needs cash settlement, but it has a long account period for many downstream sales. The liquidity is tight, the inventory is also rapidly decreasing, and the operational risks are gradually plus-sized, some enterprises chose to suspend production, leave early, and close their doors to avoid risks. But even so, the big order that has already signed a long contract still needs to be finished in the case of loss. I would rather make one order and lose one order, but also hope to keep the credibility and leave the old customers.

On the one hand, the rapid price increase of raw materials, coupled with the continuous increase of rent, water and electricity, labor costs and other costs; On the other hand, terminal payment, payment speed is slow, more than 80% of enterprises are facing cash pressure, many industries are in a desperate situation. According to previous reports of paint purchasing network, more than 300000 enterprises have closed down in many industries such as household appliances, automobiles, aluminum profiles and ships in the past year, and these industries are basically important downstream of the paint industry, it is also a big customer competing for coating enterprises.