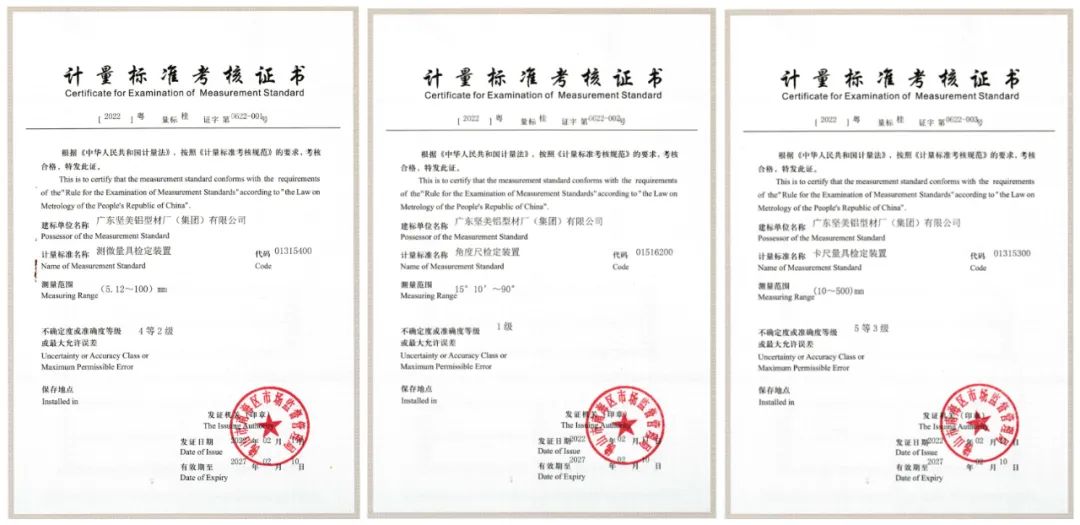

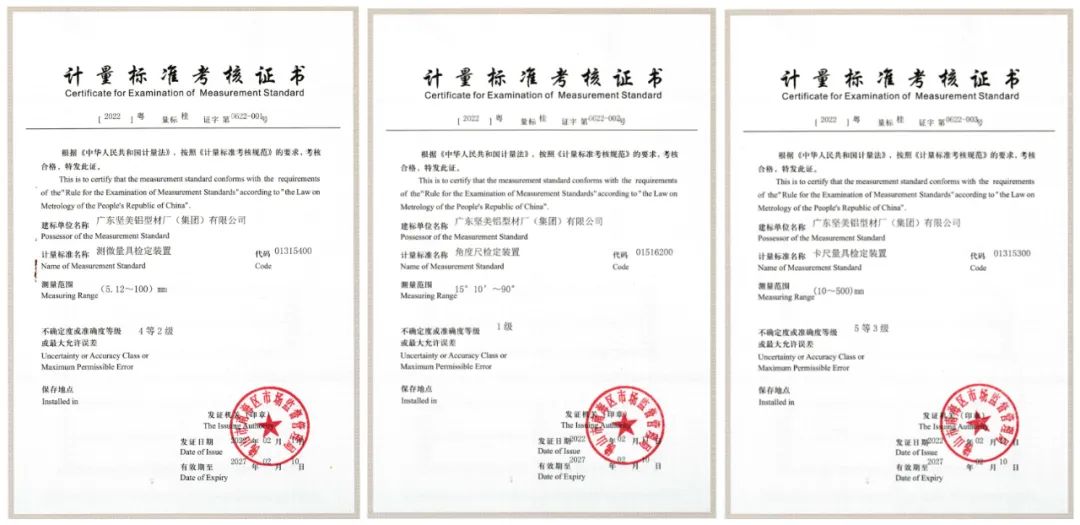

Recently, Guangdong Jianmei aluminium formation Product Factory (Group) Co., Ltd. (hereinafter referred to" jianmei aluminum ") the pass rate of various examinations such as measurement inspector operation, measurement standard management, measurement and testing environment, measurement and testing equipment are all100% excellent achievements, successfully passed the three length measurement standard certification work of micro measuring tool verification device, goniometer verification device and caliper measuring tool verification device, and became the first aluminum profile enterprise in Nanhai district to pass the length measurement standard certification and assessment.

Why do we need to carry out the measurement standard certification of enterprises? Chen Huaizhong, deputy director of Jianmei aluminum power energy management department, introduced:"During the production process of aluminum profile enterprises, they not only need technical and technological support, but also need rigorous and scientific measurement and testing data to monitor. For example, in the extrusion process, besides the quality of aluminum ingots, extrusion equipment, process temperature and geometric size will affect the yield of Extruded Products. At this time, universal goniometer, thermometer, Vernier caliper, center distance caliper, scanner, Eddy current conductors, Webster hardness tester, Barcol impressor, Leeb hardness tester and other instruments for measurement and testing. These measuring instruments can be said to be 'eyes' that control product quality, and because gauging instrument manufacturers the product variation and long-term use of the instrument may cause errors, which will not only affect the quality and performance of the product, but also affect the cost management of the enterprise, safety production and environmental protection and other aspects."

in recent years, as civil and industrial aluminum profiles are more and more widely used, the performance and precision requirements of various products are getting higher and higher. On the other hand, during the epidemic, the raw materials were price has shot up and the market competition was more intense. The accelerated changes of these market trends put forward higher requirements for the quality improvement and cost control of enterprises.

If you want to produce high-precision and high-quality industrial aluminum profiles, you must ensure that the "eyes" of measuring instruments are accurate. Therefore, strong and beautiful aluminum materials since 2020, it has decided to prepare for the establishment of measurement standards, to realize the legalization of self-inspection and verification of measuring instruments in the company, and to pass purchase testing standard instruments, measurement and verification standard instruments, etc. More than 30 professional instruments, and will be prepared to build a measurement verification room in accordance with the measurement regulations ; Determine the measuring and testing points in each link of the production process, equip the measuring instruments that meet the use requirements, compile the measuring instrument management account, formulate the classification management method of measuring instruments and the periodic verification plan, ensure the comprehensiveness, accuracy and effectiveness of measurement data. At the same time, Jianmei aluminum also implemented a number of internally controlled standard strict with national standards within the enterprise, and established the "big data" quality traceability system realizes the quality control and traceability of the whole process such as process parameters, quality of each process and quality of finished products. "The next operation can only be performed when all test data is superior to the standard. Every time we finish a job, we will record its process data and inspection results, such as production batch, quality status, product specifications, models and situation analysis, and timely control the product quality." Chen Huaizhong introduced.

The certification of the three length measurement standards is a milestone event for the improvement of the management of the measurement standards of Jianmei aluminum, but this is only the beginning. At present, Jianmei aluminum is building a professional measurement team, and professionals will train the theory, practical operation and filling of verification records of measurement personnel one by one according to the requirements of verification regulations. In the next step, prepare for the certification of measurement standards such as thermal temperature primary instrument and secondary instrument, and establish the verification standards of pressure gauge (non-strong inspection part) and measurement standards such as electric energy meter, voltmeter and ammeter.

"Adhere to the pursuit of perfection" is the brand concept of firm beauty, whether in terms of product quality or enterprise development quality, firm beauty is always strict with self-discipline, dare to be the first, and do not let go of any details of improvement. It is this persistence that has created today's strong industry status. In the future, Jianmei aluminum will continue to promote the standardized construction of production management and repay users' expectations with solid quality."Insist on pursuing perfection" to the end.