Recently, China Nonferrous Metals Industry Association organized a video conference to listen to the report on two scientific and technological achievements of Guiyang Institute, carefully reviewed relevant technical materials, and conducted inquiries, exchanges and guidance on the project.

After evaluation, Guiyang hospital "Aluminium electrolysis flue gas efficient emission reduction, energy saving and low consumption purification technology" the overall technology has reached the international advanced level, and it occupies the international leading level in the aspects of system energy saving, consumption reduction and defluorination purification technology and equipment; "Key technologies and complete sets of equipment for anode guide rod assembly repair process automation" the overall technology is at the international leading level.

Aluminium electrolysis flue gas efficient emission reduction, energy saving and low consumption purification technology

the project has developed the self-balancing technology of smoke distribution of electrolytic cell smoke exhaust pipe network, alumina dual-channel-two-stage countercurrent adsorption high-efficiency purification technology, self-ejector reactor and fresh alumina heavy immersion overflow separation technology, the technology of self-heating crystallization and recovery of desulfurization wastewater applies the technology of flue gas porous distribution, low resistance and high efficiency desulfurization to aluminium electrolysis industry for the first time. This technology can greatly improve the purification efficiency and reduce pollutant emissions on the premise of reducing the alumina breakage rate and reducing the usage of circulating alumina, and cure the "pain point" of wet desulfurization wastewater in aluminum industry; it can reduce the heat dissipation in the upper part of the electrolytic cell, reduce the damage rate of alumina, reduce the unit consumption per ton of aluminum fluoride salt and the loss of alumina, effectively promoting the technological progress of aluminum electrolysis industry.

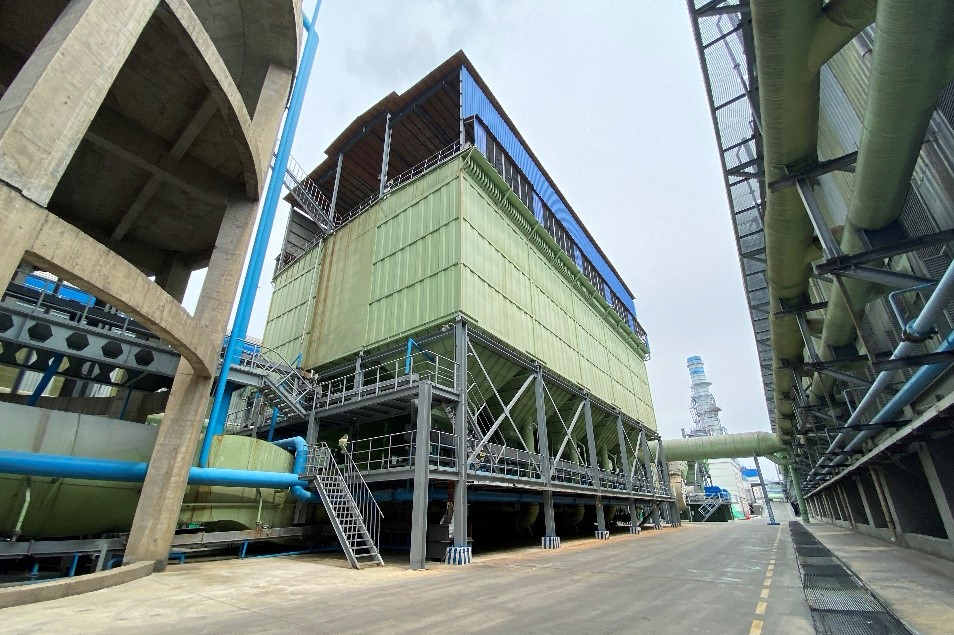

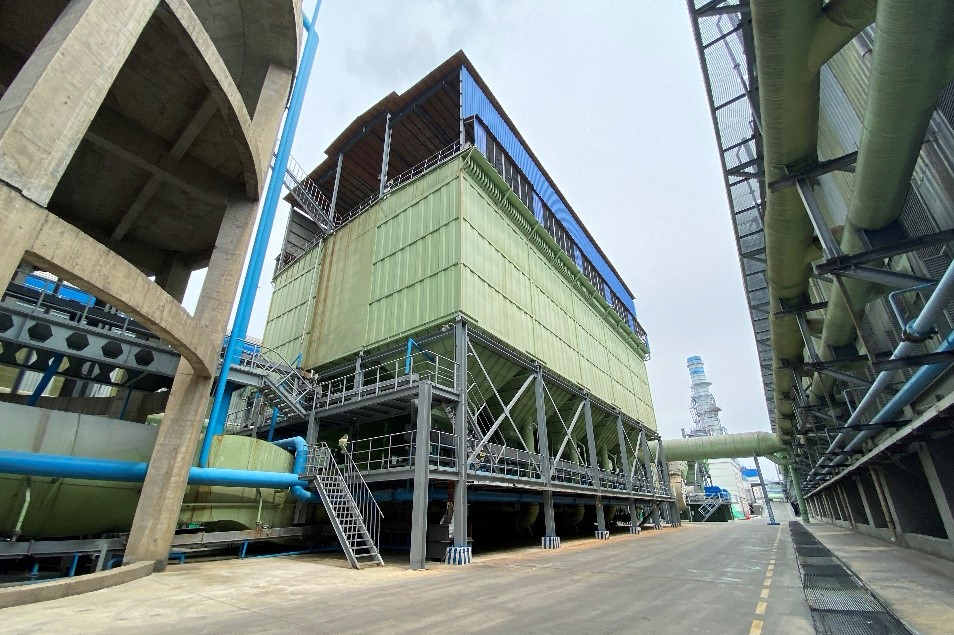

Overall appearance diagram of system equipment

purification effect picture after using Guangyuan Zhongfu technology

key technologies and complete sets of equipment for anode guide rod assembly repair process automation

the project has developed new technology of narrow seam gas protection automatic welding and resistance thermal pressure welding, key technology and complete set of equipment of the whole process automation of anode guide rod assembly repair, realizing the online and circulation of anode guide rod, sawing of waste steel claws, the whole process of feeding and alignment of steel rods to be welded, gun dropping of welding guns and welding repair is automated. This technology realizes the whole process automation of anode guide rod assembly maintenance, promotes the intelligent production of electrolytic aluminum enterprises, is of great significance to the aluminum industry to improve production efficiency, transform and upgrade, and effectively promotes the technological progress of aluminum electrolysis industry.

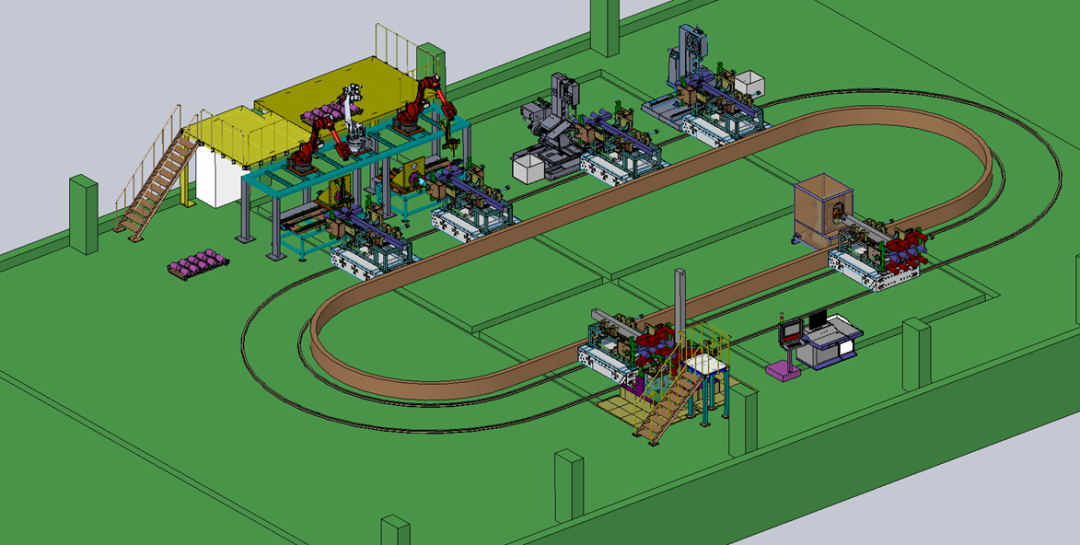

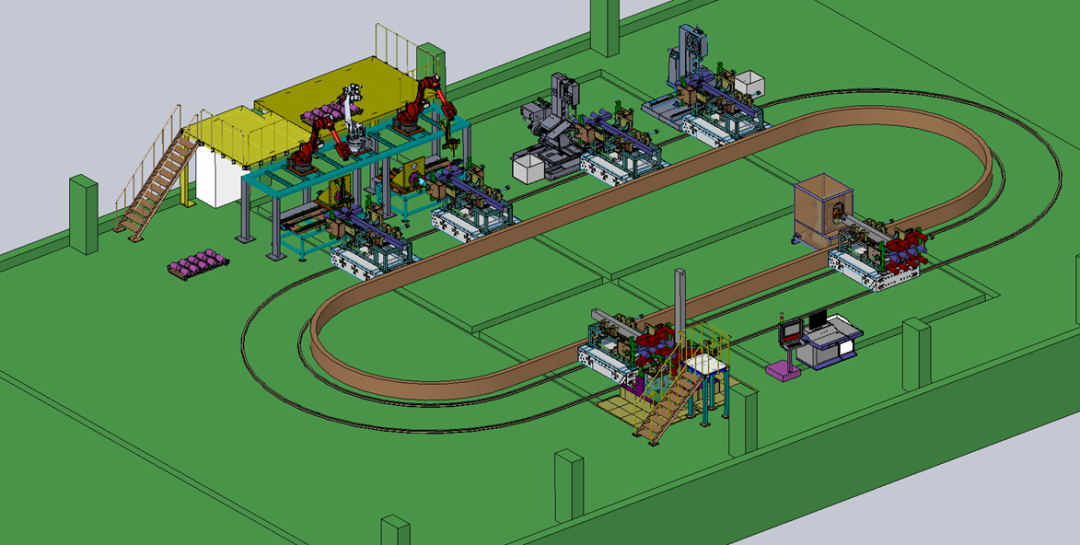

Anode steel talons full-process automatic welding repair production line implementation site

automatic production line plan